- Home

- Products

- Image Analysis

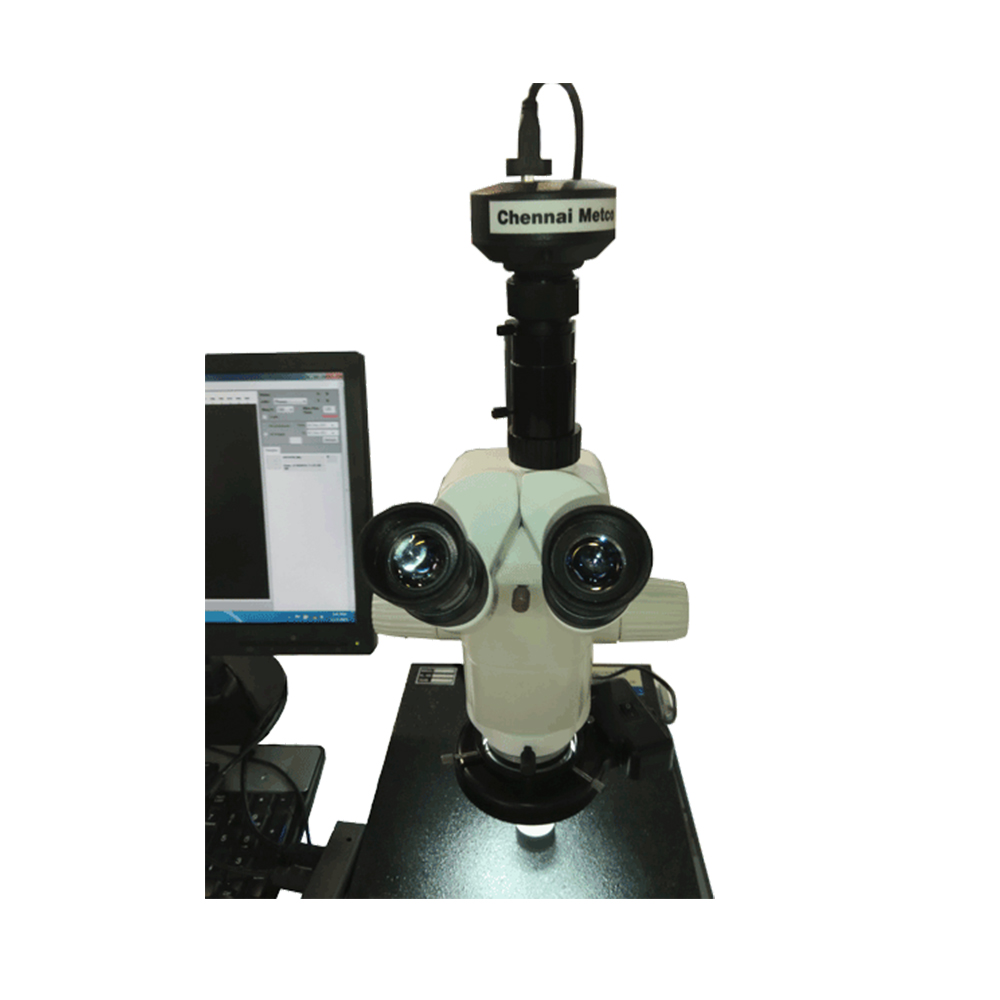

- Chennai Metco Image Macro Analysis Weld Met Software

If you want to find out more about

Chennai Metco Image Macro Analysis Weld Met Software

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Chennai Metco Image Macro Analysis Weld Met Software 1.0 has been devised as an image processing software that can help you to inspect the critical quality of welding based on its macrostructure. In manufacturing, welds are used to join two or more metal surfaces with varieties of results and microstructural connections. Because these connections may encounter loads and fatigue during the product lifetime, there is a chance they may fail if not inspected to a certified specification. Methods of weld testing and analysis are used to assure the quality and correctness of the weld after it is completed which also refers to testing and imagery analysis focused on the technological actions to check for the presence, position, and extent of welds. Chennai Metco Image Macro Analysis Weld Met Software can also be used as complementary software to the company's other destructive methods including acid etch testing, back bend testing, tensile strength break testing, nick break testing, and free bend testing. In any case, graphical image evidence is also essential in making the testing reports on the non-destructive methods, which include; fluorescent penetrate tests, magnaflux tests, eddy current (electromagnetic) tests, hydrostatic testing, tests using magnetic particles, X-rays and gamma ray-based methods and acoustic emission techniques. Other methods including ferrite and hardness testing are also applicable for macro image analysis. Quantifying metallographic features such as grain size, porosity, phase analysis, metallurgical inclusions, nodularity, coating thickness and other metallurgical testing features including measuring the thickness of the welded joints are the basic need for Characterization. And this characterization could be done with ease, with the wide range of image analysis software offered by Chennai Metco Weld Met. Chennai Metco Image Macro Analysis Weld Met Software Features: Chennai Metco Image Macro Analysis Weld Met Software can also be used as complementary software to the company's other destructive methods including acid etches testing, back bend testing, tensile strength break testing, nick break testing, and free bend testing. User-friendly software GUI with the typical looks Analyze the weld quality parameters like depth penetration, percentage penetration, leg lengths, throat and roots, and many more. Inspection is manually conducted by an inspector using imaging equipment such as a microscope or other means.

Chennai Metco Image Macro Analysis Weld Met Software 1.0 has been devised as an image processing software that can help you to inspect the critical quality of welding based on its macrostructure. In manufacturing, welds are used to join two or more metal surfaces with varieties of results and microstructural connections. Because these connections may encounter loads and fatigue during the product lifetime, there is a chance they may fail if not inspected to a certified specification.

Methods of weld testing and analysis are used to assure the quality and correctness of the weld after it is completed which also refers to testing and imagery analysis focused on the technological actions to check for the presence, position, and extent of welds. Chennai Metco Image Macro Analysis Weld Met Software can also be used as complementary software to the company's other destructive methods including acid etch testing, back bend testing, tensile strength break testing, nick break testing, and free bend testing. In any case, graphical image evidence is also essential in making the testing reports on the non-destructive methods, which include; fluorescent penetrate tests, magnaflux tests, eddy current (electromagnetic) tests, hydrostatic testing, tests using magnetic particles, X-rays and gamma ray-based methods and acoustic emission techniques. Other methods including ferrite and hardness testing are also applicable for macro image analysis.

Quantifying metallographic features such as grain size, porosity, phase analysis, metallurgical inclusions, nodularity, coating thickness and other metallurgical testing features including measuring the thickness of the welded joints are the basic need for Characterization. And this characterization could be done with ease, with the wide range of image analysis software offered by Chennai Metco Weld Met.

Chennai Metco Image Macro Analysis Weld Met Software Features:

- Chennai Metco Image Macro Analysis Weld Met Software can also be used as complementary software to the company's other destructive methods including acid etches testing, back bend testing, tensile strength break testing, nick break testing, and free bend testing.

- User-friendly software GUI with the typical looks

- Analyze the weld quality parameters like depth penetration, percentage penetration, leg lengths, throat and roots, and many more.

- Inspection is manually conducted by an inspector using imaging equipment such as a microscope or other means.

TECHNICAL SPECIFICATION

Chennai Metco Image Macro Analysis Weld Met Software Ordering Guide:

Contact us for details

Request a Quote

Request A Quote

Please complete the below form to receive further information.