If you want to find out more about

Chennai Metco Petrography Sectioning Baincut Geo

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

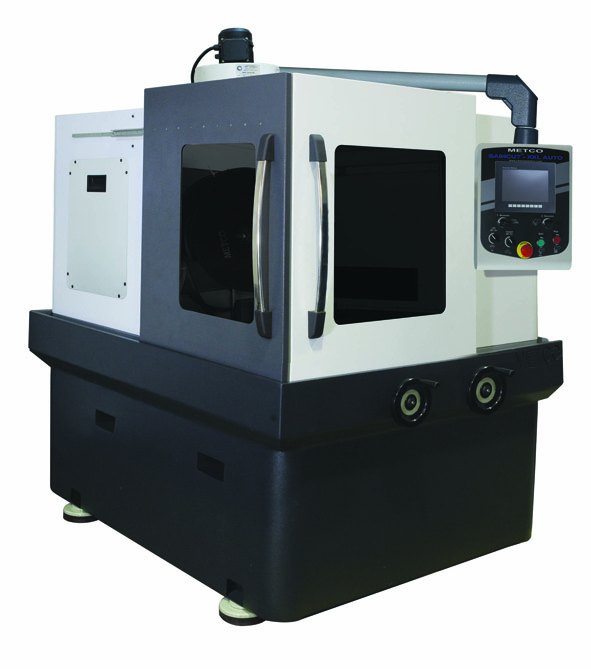

Chennai Metco Baincut Geo is a sturdy cutter for abrasive sectioning of rocks, ingots, ore, fossil, ceramic and mineral samples to classify the information acquired during the petrographic analysis. Powered by a heavy-duty 3 Phase 5 HP servo motor and fine abrasive disc, Chennai Metco Baincut Geo is suitable for thinner sectioning of the layered specimen with brittle properties or rare value. Equipped with Clamping Vice, Vertical Clamp, and a Double Saddle clamp, any shape of a specimen of a maximum ⌀ of 90 mm can be easily locked, you can have a highly predictive result and repeatable macro-surface quality with proper vice and locking setup. Sectioning a specimen with an appropriate method is the crucial step for studying the microstructure of materials. Various surfaces of the material with smaller sizes such as metals, fibers, plastic, ceramic and mineral samples with a medium level of toughness can be examined conveniently. The aim is to get an excellent surface condition with minimal damage. Material sectioning should be done with an abrasive cutter with a generous amount of coolant to prevent excessive heat from frictions which may alter the microstructure and produce false metallographic characterization. After the careful sectioning stage, a detailed analysis of minerals can be further examined by using optical mineralogy, so that the micro-texture and structure can be produced. A thinner and smoother macro surface will provide clearer quality imaging. For the modern petrographic lab, the Baincut Geo machine is essential with both wet and dry operations where further Electron microprobe analysis of individual grains is to be examined for rock chemical analysis (atomic absorption, X-ray fluorescence, and laser-induced breakdown spectroscopy). For finer surface preparation then the next step will be grinding and polishing finer abrasive particles with BAINPOL Auto PMV series until the desired surface quality is ready and the metallographic structure of the specimen can be observed and measured in detail with Vision engineering TIM5 or digital, optical, or electron microscopy. Chennai Metco Petrography Sectioning Baincut Geo Features: Secure vice and clamps for cutting specimens of up to 90 mm diameter 5 HP, 3-phase motor with a powerful torque to cut hard and brittle minerals Different abrasive disc sizes can be accommodated 8”/10”/12” Fluid X- Movement for Cross Sectioning – 50mm and Y Movement for Longitudinal Sectioning – 150mm Ergonomic manual Z movement handle Dry & Wet type system for different applications, 50 liters of coolant recirculation tank. Can also be improvised with an attached blower or suction hose for certain clean room application The door Limit Switch System in the machine ensures that the cutting process is stopped immediately when the door is opened. An emergency stopper is also provided along with the machine. Rigid stainless steel platform with 8 mm T Slot secure Internal illumination to help visual observation during cutting.

Chennai Metco Baincut Geo is a sturdy cutter for abrasive sectioning of rocks, ingots, ore, fossil, ceramic and mineral samples to classify the information acquired during the petrographic analysis. Powered by a heavy-duty 3 Phase 5 HP servo motor and fine abrasive disc, Chennai Metco Baincut Geo is suitable for thinner sectioning of the layered specimen with brittle properties or rare value. Equipped with Clamping Vice, Vertical Clamp, and a Double Saddle clamp, any shape of a specimen of a maximum ⌀ of 90 mm can be easily locked, you can have a highly predictive result and repeatable macro-surface quality with proper vice and locking setup.

Sectioning a specimen with an appropriate method is the crucial step for studying the microstructure of materials. Various surfaces of the material with smaller sizes such as metals, fibers, plastic, ceramic and mineral samples with a medium level of toughness can be examined conveniently. The aim is to get an excellent surface condition with minimal damage. Material sectioning should be done with an abrasive cutter with a generous amount of coolant to prevent excessive heat from frictions which may alter the microstructure and produce false metallographic characterization.

After the careful sectioning stage, a detailed analysis of minerals can be further examined by using optical mineralogy, so that the micro-texture and structure can be produced. A thinner and smoother macro surface will provide clearer quality imaging. For the modern petrographic lab, the Baincut Geo machine is essential with both wet and dry operations where further Electron microprobe analysis of individual grains is to be examined for rock chemical analysis (atomic absorption, X-ray fluorescence, and laser-induced breakdown spectroscopy). For finer surface preparation then the next step will be grinding and polishing finer abrasive particles with BAINPOL Auto PMV series until the desired surface quality is ready and the metallographic structure of the specimen can be observed and measured in detail with Vision engineering TIM5 or digital, optical, or electron microscopy.

Chennai Metco Petrography Sectioning Baincut Geo Features:

- Secure vice and clamps for cutting specimens of up to 90 mm diameter

- 5 HP, 3-phase motor with a powerful torque to cut hard and brittle minerals

- Different abrasive disc sizes can be accommodated 8”/10”/12”

- Fluid X- Movement for Cross Sectioning – 50mm and Y Movement for Longitudinal Sectioning – 150mm

- Ergonomic manual Z movement handle

- Dry & Wet type system for different applications, 50 liters of coolant recirculation tank.

- Can also be improvised with an attached blower or suction hose for certain clean room application

- The door Limit Switch System in the machine ensures that the cutting process is stopped immediately when the door is opened.

- An emergency stopper is also provided along with the machine.

- Rigid stainless steel platform with 8 mm T Slot secure

- Internal illumination to help visual observation during cutting.

TECHNICAL SPECIFICATION

Chennai Metco Petrography Sectioning Baincut Geo Ordering Guide:

| Specification | Chennai Metco Baincut Geo |

| Working Area | Dry and wet cutting with specimen diameter up to 90mm |

| 5 HP Motor, 3 Phase | |

| Abrasive wheel | Different Wheel size can be accommodated 8”/10”/12” |

| Operation range |

X- Movement for Cross Sectioning – 50mm Y Movement for Longitudinal Sectioning – 150mm Ergonomic Z Movement Handle Vice to hold normal diametric samples Vertical Clamp for holding of Irregular shaped specimens Double Saddle Clamp |

| Clamping vise | Stainless Steel Platform with 8mm T Slot |

| Illumination | LED Lamp in the working area for clear illumination |

Request a Quote

Request A Quote

Please complete the below form to receive further information.