If you want to find out more about

DoALL Friction Saw Blade Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

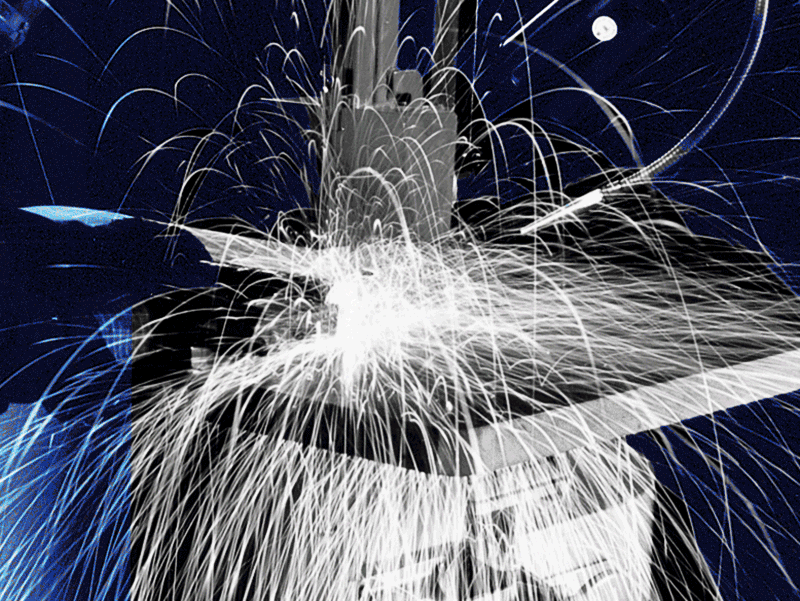

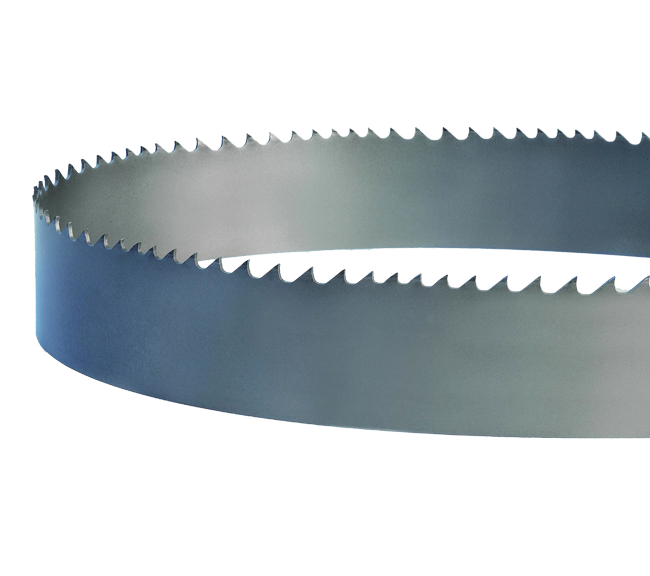

Best selling product since 1957, DoALL Friction Saw Blade is designed from silicon-enhanced carbon steel to improve the blade's surface properties when working with high friction, heat and vibration from cutting high tensile sheet with minimal or no lubrication (any ferrous material etc.). The mechanical properties, such as tensile strength, uniform elongation, and the combination of tensile strength/ductility of DoALL Friction Saw Blade were improved as the phosphorus (in the presence of silicon) was increased. This is attributed to the strain-induced transformation of retained austenite during tensile deformation in the cutting process. Compared to regular HSS model, DoALL Friction Saw Blade is more resistant to this extreme disturbance. Depends on your machinery set up, DoALL Friction Saw Blade performs consistently balanced between power delivery to cut ratio for a cost effective job. DoALL Friction Saw Blade is versatile and particularly suitable when you need the reliability in working with various corrugated zinc, layers of ferrous metal and iron blanks for CNC fabrication which may varies from each customer. Features Silicon-enhanced carbon steel Special wide set Hardened tooth tips Benefits Slower set wear and longer fatique life Applications Friction sawing of ferrous metals with any hardness up to 25 mm thick at speeds exceeding 1.500 m/min.

Best selling product since 1957, DoALL Friction Saw Blade is designed from silicon-enhanced carbon steel to improve the blade's surface properties when working with high friction, heat and vibration from cutting high tensile sheet with minimal or no lubrication (any ferrous material etc.). The mechanical properties, such as tensile strength, uniform elongation, and the combination of tensile strength/ductility of DoALL Friction Saw Blade were improved as the phosphorus (in the presence of silicon) was increased. This is attributed to the strain-induced transformation of retained austenite during tensile deformation in the cutting process. Compared to regular HSS model, DoALL Friction Saw Blade is more resistant to this extreme disturbance.

Depends on your machinery set up, DoALL Friction Saw Blade performs consistently balanced between power delivery to cut ratio for a cost effective job. DoALL Friction Saw Blade is versatile and particularly suitable when you need the reliability in working with various corrugated zinc, layers of ferrous metal and iron blanks for CNC fabrication which may varies from each customer.

Features

- Silicon-enhanced carbon steel

- Special wide set

- Hardened tooth tips

Benefits

- Slower set wear and longer fatique life

Applications

- Friction sawing of ferrous metals with any hardness up to 25 mm thick at speeds exceeding 1.500 m/min.

TECHNICAL SPECIFICATION

DoALL Friction Saw Blade Ordering Guide:

| Metric | Friction | ||

| Width | Gauge | 10 | |

| 13 | 0,8 | 310-037 | |

| 20 | 0,9 | 310-094 | |

| 25 | 0,9 | 310-136 | |

| 32 | 0,9 | 310-359* | |

| * | = Available in 91,4 m or 152,4 m coils | ||

You can also download DoALL Saw Blade catalogs here

Request a Quote

Request A Quote

Please complete the below form to receive further information.