If you want to find out more about

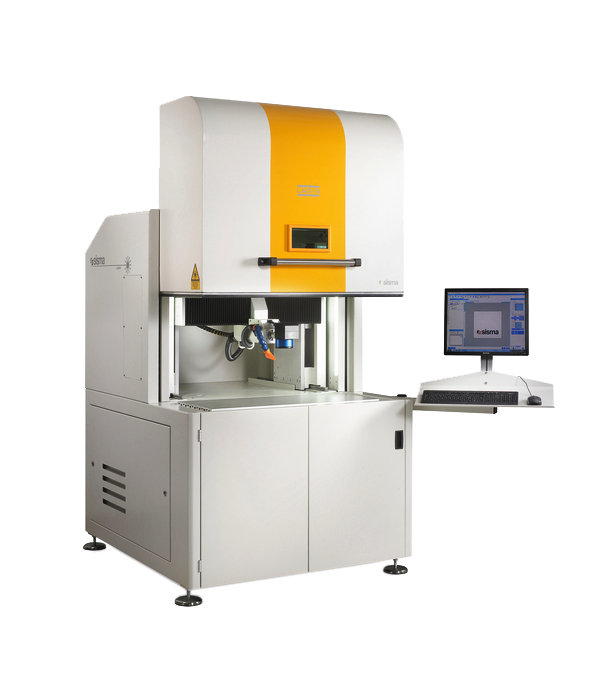

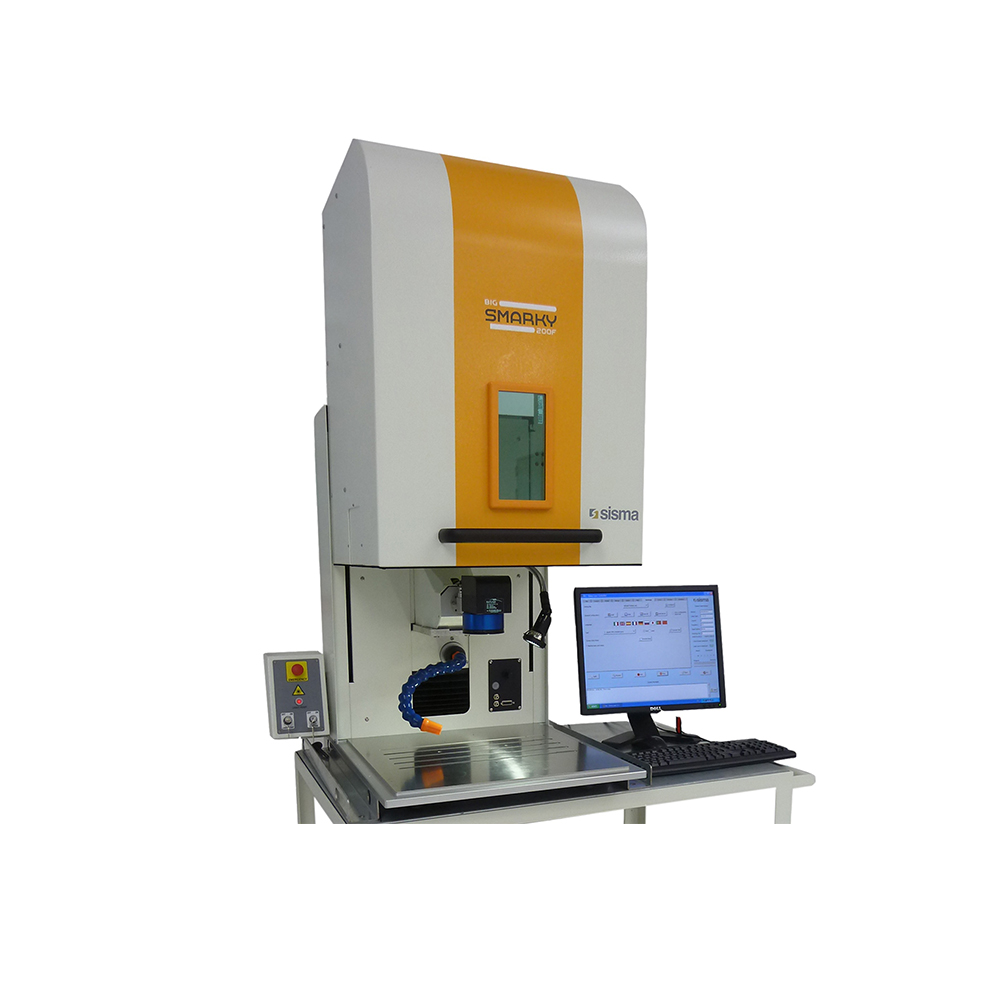

Sisma Laser Engraving BIG SMARK BSS 3D

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

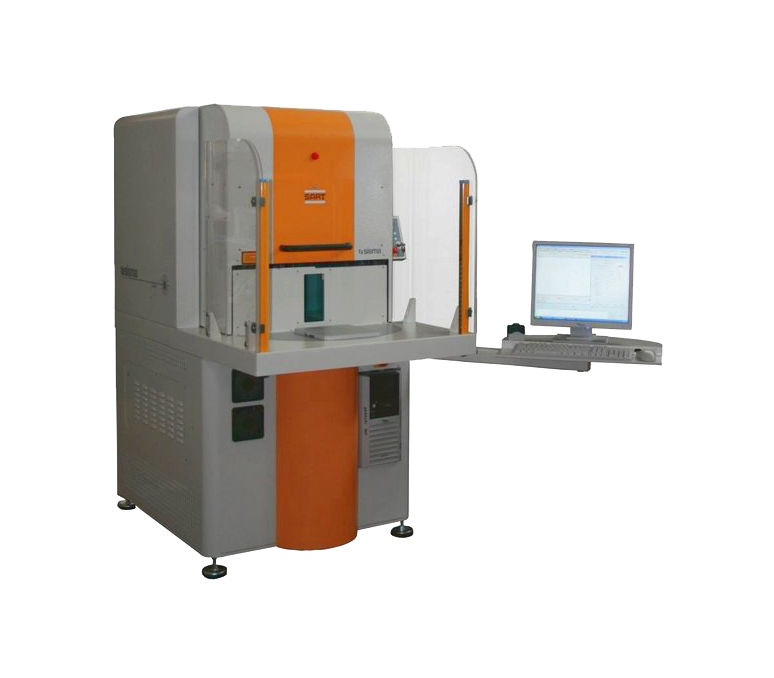

Sisma Laser Engraving BIG SMARK BSS 3D machine is devised as a versatile machine for precision engraving or deep marking at economicallly faster result. The Sisma Laser System is the specialist for 2D and 3D deep engraving on moulds, punches and electrodes through movement of the laser source on a portal with 3 axes with a range of 350 mm. From its user friendly SLC software, you can define the engraving parameter, axis, camera for object centering and positioning engraving cycles as well. The software is compatible with SVG, BMP, JPG, HTML and PLT format. You can have a beautifully accurate cutting far superior than CNC micro-milling machine even better than a Co2 laser machine. Your investment on Sisma Laser Engraving BIG SMARK BSS 3D will help you to forget all the headache on previously time consuming cutting and hazardous chemical etching routine. Thanks to its class IV laser source level, you can have a concentrated heat source with narrower and faster marking rates than comparable laser engaving brands. Sisma Laser Engraving BIG SMARK BSS 3D works by utilizing Fiber Ytterbium laser beam which emit light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser). Door can be slid all the way up to opens on 3 sides to facilitate easy access on its wide chamber (500x500 mm). This machine accomodate maximum height of piece 530 mm (F100) and can be attached with all Sisma accessories. Sisma Laser Engraving BIG SMARK BSS 3D works very well for engraving logo or initial on stainless workpiece, marking barcode on CNC product, cutting thin plate of hard metal, mould and die making, luxurious marine and consumer equipment, plumbing and lux faucet, name plates or manufacturing batch plate, and various other relief making application on any type of metal and composite surface. With Sisma's BIG SMARKY, you can do versatile marking and 2D-3D engraving with premium quality on individual work-piece. Consistency and reproducibility on mass-production thanks to the automatic pallet wharehouse also with vision control system. However, if you are looking for much laser engraving on bigger workpiece and faster pace of production, you might also wants to consider Sisma LWS. Sisma Laser Engraving BIG SMARK BSS 3D Features: Higher power than Sisma BSP Series. The centering itself can be done through an high resolution ultra compact camera; working cycles, positioning and programming are managed from the master software. Optimized for 3D deep engraving on alloy, stainless steel engraving, jewellery, precious minerals and tougher metallic surface. Cleaner working environment with fine finishing, no need for futher abrasives. Much safer and practical compared to regular milling with mixed qualities which followed by hazardous chemical etching & engraving. Using the market's highest class IV laser source technology which produce seamless marking surface. Windows PC based on PLC interface, data network (ethernet), digital I/O Manually adjusted Z shaft distance for larger object. Includes intuitive software compatible with small to medium scale application. Enclosed system and sealed laser source for minimal maintenance. Suitable for production line which requires high quality marking on medium volume application. Non consumable application unlike Co2 laser marking machine. Object stage can be attached with vise, XY table and micrometer stage. Can also be supplied with cooling panel for much efficient operation Sisma Laser Engraving BIG SMARK BSS 3D optional accessory: High precision rotary axis, static clamping device. Ragging system with winder, dynamic measuring device, Fumes aspirator

Sisma Laser Engraving BIG SMARK BSS 3D machine is devised as a versatile machine for precision engraving or deep marking at economicallly faster result. The Sisma Laser System is the specialist for 2D and 3D deep engraving on moulds, punches and electrodes through movement of the laser source on a portal with 3 axes with a range of 350 mm. From its user friendly SLC software, you can define the engraving parameter, axis, camera for object centering and positioning engraving cycles as well. The software is compatible with SVG, BMP, JPG, HTML and PLT format. You can have a beautifully accurate cutting far superior than CNC micro-milling machine even better than a Co2 laser machine.

Your investment on Sisma Laser Engraving BIG SMARK BSS 3D will help you to forget all the headache on previously time consuming cutting and hazardous chemical etching routine. Thanks to its class IV laser source level, you can have a concentrated heat source with narrower and faster marking rates than comparable laser engaving brands. Sisma Laser Engraving BIG SMARK BSS 3D works by utilizing Fiber Ytterbium laser beam which emit light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser). Door can be slid all the way up to opens on 3 sides to facilitate easy access on its wide chamber (500x500 mm). This machine accomodate maximum height of piece 530 mm (F100) and can be attached with all Sisma accessories.

Sisma Laser Engraving BIG SMARK BSS 3D works very well for engraving logo or initial on stainless workpiece, marking barcode on CNC product, cutting thin plate of hard metal, mould and die making, luxurious marine and consumer equipment, plumbing and lux faucet, name plates or manufacturing batch plate, and various other relief making application on any type of metal and composite surface. With Sisma's BIG SMARKY, you can do versatile marking and 2D-3D engraving with premium quality on individual work-piece. Consistency and reproducibility on mass-production thanks to the automatic pallet wharehouse also with vision control system. However, if you are looking for much laser engraving on bigger workpiece and faster pace of production, you might also wants to consider Sisma LWS.

Sisma Laser Engraving BIG SMARK BSS 3D Features:

- Higher power than Sisma BSP Series.

- The centering itself can be done through an high resolution ultra compact camera; working cycles, positioning and programming are managed from the master software.

- Optimized for 3D deep engraving on alloy, stainless steel engraving, jewellery, precious minerals and tougher metallic surface.

- Cleaner working environment with fine finishing, no need for futher abrasives.

- Much safer and practical compared to regular milling with mixed qualities which followed by hazardous chemical etching & engraving.

- Using the market's highest class IV laser source technology which produce seamless marking surface.

- Windows PC based on PLC interface, data network (ethernet), digital I/O

- Manually adjusted Z shaft distance for larger object.

- Includes intuitive software compatible with small to medium scale application.

- Enclosed system and sealed laser source for minimal maintenance.

- Suitable for production line which requires high quality marking on medium volume application.

- Non consumable application unlike Co2 laser marking machine.

- Object stage can be attached with vise, XY table and micrometer stage.

- Can also be supplied with cooling panel for much efficient operation

Sisma Laser Engraving BIG SMARK BSS 3D optional accessory:

- High precision rotary axis, static clamping device.

- Ragging system with winder, dynamic measuring device,

- Fumes aspirator

TECHNICAL SPECIFICATION

Sisma Laser Engraving BIG SMARK BSS 3D Ordering Guide:

| Model |

BIG SMARK 200F-3D |

BIG SMARK 400F-3D |

| Output power | 20 W | 40 W |

| Peak power | 12 kW | 12 kW |

| Pulse frequency | 1-200 kHz | 1-200 kHz |

| Wave lenght | 1064 nm | 1064 nm |

| Focal | F100, F160 (std), F254 mm | F100, F160 (std), F254 mm |

| Power supply | 230V, 50/60Hz 1ph - 1KW | 230V, 50/60Hz 1ph - 1KW |

| Cooling system | Air | Air |

| Working area with focal F160 |

100x100 mm | 100x100 mm |

| Dimensions | 1190x1900x1795 mm | 1190x1900x1795 mm |

| Net weight | 960 Kg | 960 Kg |

|

Notes: Constant ray of laser may result in higher temperature and affect the performance. Better circulation of cold air and fumes respirator are advised with pulsed mode operation for a much efficient approach. When you are using the machine with longer working time, make sure to install additional cooling panel to avoid unnecessary down time. However, if you are looking for much affordable alternative for marking laser on smaller range, you might also wants to consider Sisma Marking Laser LOGO Series, or if you would like a mould repair laser welding unit, you can opt for Sisma SWA mold repair specialist. |

Request a Quote

Request A Quote

Please complete the below form to receive further information.