- Home

- Products

- Optical

- Scan Measurement

- Sylvac Non-Contact Optical Measuring Scan F60

If you want to find out more about

Sylvac Non-Contact Optical Measuring Scan F60

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Sylvac Non-Contact Optical Measuring Scan F60 is a vertical scanner with an exclusive helix tilting system that enables measurements of cylindrical components to be taken up to Ø 60mm in diameter and 300mm in length with a 30° inclination. Sylvac Non-Contact Optical Measuring Scan F60 works using the drop shadow principle; the device makes an optical scan of the component to produce a highly magnified, high-resolution image, on which it measures dimensions such as lengths, diameters, angles, radii, chamfers, threads, etc. There is also a component rotation system so that any form errors such as runout, cylindricity, etc. can be measured. You can also use this device for an improvised gauging rig with Sylvac's gaging multiplexer software. The Non-Contact Optical Measuring Scan F60 is suitable for the first-off part, control in the process (SPC), sampling, or 100% inspection. The system incorporates the highest resolution CCD sensors that combine 2 x 7.000 elements linear arrays, with a patented 7.5° system, which would correspond to a camera with a resolution of 200 megapixels. As the part profile is projected, these sensors, which are capable of detecting the slightest changes at the pixel level, act as a light-sensitive rule. Sylvac Non-Contact Optical Measuring Scan F60 will unlock higher levels of precision without the additional cost to human resources. Sylvac Non-Contact Optical Measuring Scan F60 will give you a competitive edge with the instant return, especially when working on critical cylindrical concentricity components, such as aerospace drive shafts, electrical motors, drills and cutting tools, automotive shafts, medical devices, connectors, dental screws and implants, hydraulics parts, rollers, turbines parts, CNC turned parts, etc. Sylvac Non-Contact Optical Measuring Scan F60 Features: Concept Reflex SCAN is patented for measuring cylindrical workpieces without preprogramming Complete the 2D part scan in less than 3 sec Reduce inspection time Reduce scrap Increase productivity Quick return on investment, typically within 6 months New software Reflec SCAN+

Sylvac Non-Contact Optical Measuring Scan F60 is a vertical scanner with an exclusive helix tilting system that enables measurements of cylindrical components to be taken up to Ø 60mm in diameter and 300mm in length with a 30° inclination.

Sylvac Non-Contact Optical Measuring Scan F60 works using the drop shadow principle; the device makes an optical scan of the component to produce a highly magnified, high-resolution image, on which it measures dimensions such as lengths, diameters, angles, radii, chamfers, threads, etc. There is also a component rotation system so that any form errors such as runout, cylindricity, etc. can be measured. You can also use this device for an improvised gauging rig with Sylvac's gaging multiplexer software.

The Non-Contact Optical Measuring Scan F60 is suitable for the first-off part, control in the process (SPC), sampling, or 100% inspection. The system incorporates the highest resolution CCD sensors that combine 2 x 7.000 elements linear arrays, with a patented 7.5° system, which would correspond to a camera with a resolution of 200 megapixels. As the part profile is projected, these sensors, which are capable of detecting the slightest changes at the pixel level, act as a light-sensitive rule.

Sylvac Non-Contact Optical Measuring Scan F60 will unlock higher levels of precision without the additional cost to human resources. Sylvac Non-Contact Optical Measuring Scan F60 will give you a competitive edge with the instant return, especially when working on critical cylindrical concentricity components, such as aerospace drive shafts, electrical motors, drills and cutting tools, automotive shafts, medical devices, connectors, dental screws and implants, hydraulics parts, rollers, turbines parts, CNC turned parts, etc.

Sylvac Non-Contact Optical Measuring Scan F60 Features:

- Concept Reflex SCAN is patented for measuring cylindrical workpieces without preprogramming

- Complete the 2D part scan in less than 3 sec

- Reduce inspection time

- Reduce scrap

- Increase productivity

- Quick return on investment, typically within 6 months

- New software Reflec SCAN+

TECHNICAL SPECIFICATION

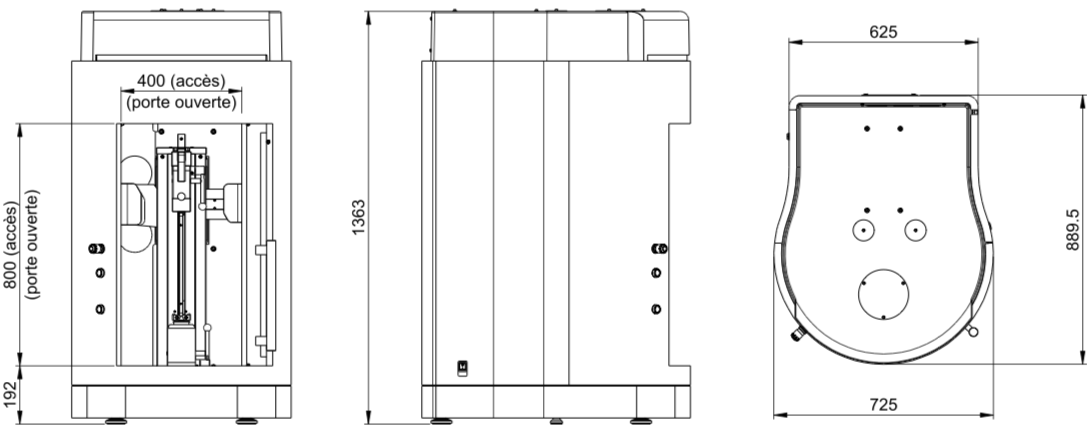

Sylvac Non-Contact Optical Measuring Scan F60 Dimensions:

Sylvac Non-Contact Optical Measuring Scan F60 Ordering Guide:

| 902.4060 | 902.4065 | ||||

| Sylvac SCAN F60 | Sylvac SCAN F60T | ||||

| Diameter | Length | Diameter | Length | ||

| Measuring range | mm | 64 | 300 | 64 | 300 |

| Resolution up to | mm | 0.0001 | 0.0001 | 0.0001 | 0.0001 |

| Mas. error | µm | (1 + D[mm]/100) µm | (3 + L[mm]/200) µm | (1 + D[mm]/100) µm | (3 + L[mm]/200) µm |

| Repeatability | µm | 0.5 | 1.0 | 0.5 | 1.0 |

| Holding capacity diameter | mm | 120 | 315 | 120 | 315 |

| Headstock | Rotary headstock for static and dynamic measurements | ||||

| tilting for thread measurement | - | • 30° | |||

| Max. weight of part | kg | 10 | |||

| Machine's weight | kg | 265 | |||

Request a Quote

Request A Quote

Please complete the below form to receive further information.