- Home

- Products

- Cutting Tools

- Turning

- WIDIA™ Bar Peeling Toolholders

If you want to find out more about

WIDIA™ Bar Peeling Toolholders

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Indexable Milling • 90° Shoulder Mills • M690 Series • Tool Bodies M690 • Shell Mills SD1506 WIDIA™ Tools for Bar Peeling is a brilliant solution and economical machining operation used for either shaping and removing of crust, surface deformations, and seams formed on billets and tubes during hot rolling. Any fabrication of cylindrical surfaces on blank bars (e.g., round bars, wires, blocks, and pipes) can be worked until smooth finishes of the workpiece meets the microns tolerances and ovality to be subsequently machined on collet lathes or to undergo extrusion. Your investment on WIDIA™ Tool's clever designs, will allows your company to works with higher feed rates as during the bar peeling process of scales, cracks, and debris enclosures are creating lesser vibrations and lower heat unlike no other. The surface of workpiece, can be varying from 0.2mm to 3mm in thickness, is removed depending on the bar diameter by carbide inserts in the tool holder fitted to the cutting heads and moving with a rotary action. The bars are guided into the cutting zone, where they are centered by rollers, then extracted by the same method on the inlet side. The material moves linearly only during the peeling operation. The WIDIA product portfolio defines the ultimate standard for productivity-improving products. Best-in-class performance is an essential step toward best-in-class cost-cutting and improving your fabrication quality as in Aerospace, die/mold and many other industries regularly encounter high-strength, difficult-to-machine materials requiring high torques, feeds, and forces. Furthermore, PDF catalog on metric can be downloaded here and on inches here (103 MB) WIDIA™ Toolholder series for bar peeling specialty are: 1. WDHF 20, WDH 20, WDH 50 T, and WDH 50 Adjustable 2. WDH 50, WDH 50 K, and WDH 75 T 3. WDHE 80, WDH 100, WDH 360, and S 80

Indexable Milling • 90° Shoulder Mills • M690 Series • Tool Bodies M690 • Shell Mills SD1506

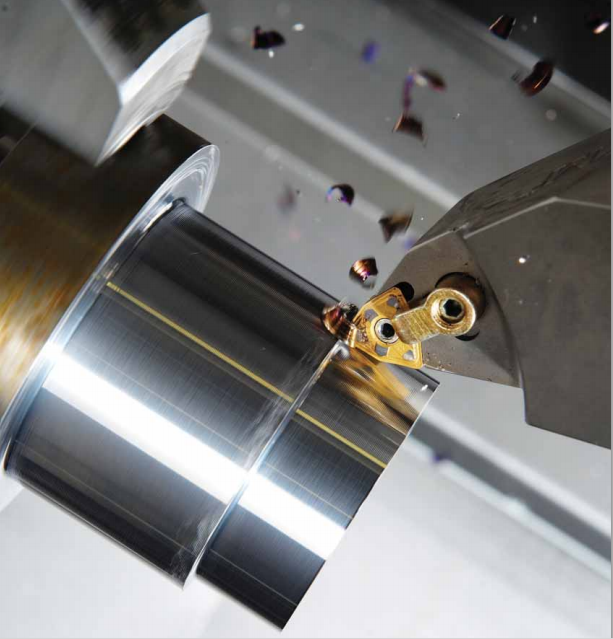

WIDIA™ Tools for Bar Peeling is a brilliant solution and economical machining operation used for either shaping and removing of crust, surface deformations, and seams formed on billets and tubes during hot rolling. Any fabrication of cylindrical surfaces on blank bars (e.g., round bars, wires, blocks, and pipes) can be worked until smooth finishes of the workpiece meets the microns tolerances and ovality to be subsequently machined on collet lathes or to undergo extrusion.

Your investment on WIDIA™ Tool's clever designs, will allows your company to works with higher feed rates as during the bar peeling process of scales, cracks, and debris enclosures are creating lesser vibrations and lower heat unlike no other. The surface of workpiece, can be varying from 0.2mm to 3mm in thickness, is removed depending on the bar diameter by carbide inserts in the tool holder fitted to the cutting heads and moving with a rotary action. The bars are guided into the cutting zone, where they are centered by rollers, then extracted by the same method on the inlet side. The material moves linearly only during the peeling operation.

The WIDIA product portfolio defines the ultimate standard for productivity-improving products. Best-in-class performance is an essential step toward best-in-class cost-cutting and improving your fabrication quality as in Aerospace, die/mold and many other industries regularly encounter high-strength, difficult-to-machine materials requiring high torques, feeds, and forces. Furthermore, PDF catalog on metric can be downloaded here and on inches here (103 MB)

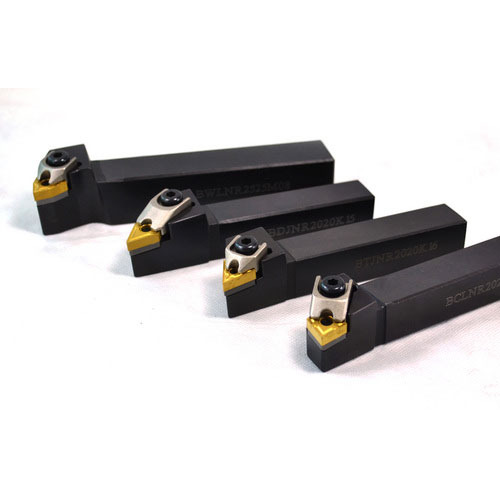

WIDIA™ Toolholder series for bar peeling specialty are:

1. WDHF 20, WDH 20, WDH 50 T, and WDH 50 Adjustable

2. WDH 50, WDH 50 K, and WDH 75 T

3. WDHE 80, WDH 100, WDH 360, and S 80

TECHNICAL SPECIFICATION

WIDIA™ Bar Peeling Toolholders

WDHF 20, WDH 20, WDH 50 T, and WDH 50 Adjustable

Request a Quote

Request A Quote

Please complete the below form to receive further information.