- Home

- Products

- Tool Holders

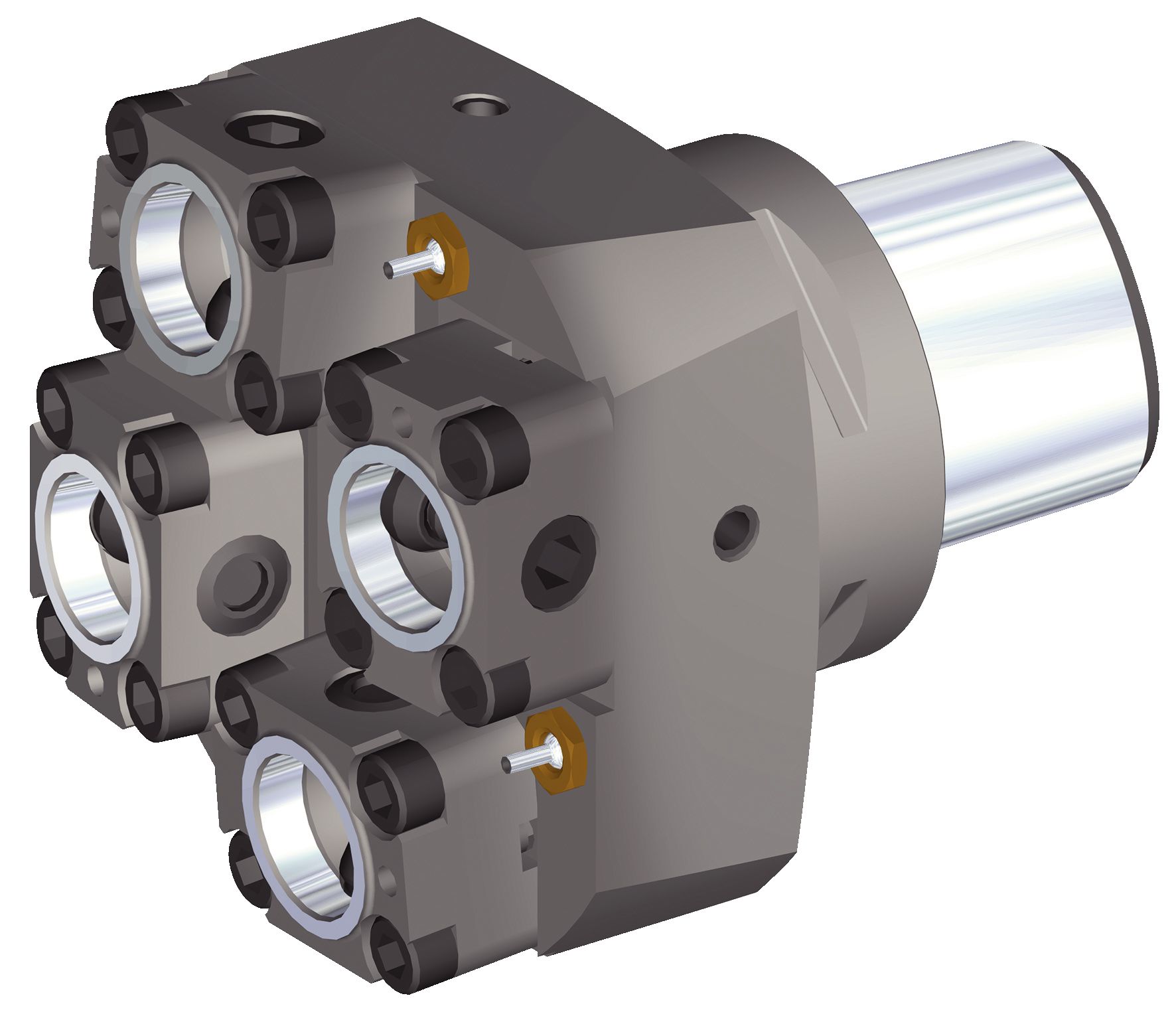

- WIDIA™ Erickson™ HSK Series high-precision collet chuck

If you want to find out more about

WIDIA™ Erickson™ HSK Series high-precision collet chuck

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

WIDIA™ devised high-precision collet chuck for multiple applications including milling, drilling, reaming, and tapping, while maintaining runout accuracies of 0.003 mm (0.0001 inches) at 3xD. Manufacturers of many high-precision components in industries such as aerospace, transportation, die and mold, are now benifitting between producing high-tolerance parts with the production capability of higher tensile work-piece and coping with reality of future prospect as well. Aerospace, die/mold and many other industries regularly encounter high-strength, difficult-to-machine materials requiring high torques, feeds, and forces. Hence, the danger of milling cutters being pulled out of the tool holder as the extreme forces has significantly increased. This is at least true for tool holders that offer precision clamping with good concentricity such as shrink-fit. Such toolholders work with frictional locking, but their clamping force is often not sufficient for roughing and The new WIDIA universal precision collet is available with Safe-Lock pull-out protection from Haimer. Helical grooves are ground into the shank of the milling tool that, together with the respective pin drivers in the chuck, prevent the tool from spinning or being pulled out of the holder altogether under extreme machining conditions. The helical path of the Safe-Lock grooves also allows for adjusting tool length, meaning tools can be reground and pre-set as usual. WDIA collet chuck solution upgrades fabricator's performance and final part tolerance as well as working faster and save working hours. The WIDIA™ High-Precision Collet Chuck Series features: Added versatility with the ability to continue using standard ER collets while upgrading to precision collets. This advantages are essential in economizing cost in tools procurement. Thicker chuck walls and a stronger outer form for added rigidity and lower vibration for longer spindle and tool life. A unique sealed-by-design precision collets (6 – 20 mm or 0.24 – 0.79 inches) for excellent coolant delivery and longer tool life. Improved clamping designs allows for better and repeatable balancing, all contributing to higher accuracy. Suitable for fully autonomous operation as the sturdy designs are sufficient in securing workpiece of high-strenght material. PDF catalog on metric can be downloaded here and on inches here

WIDIA™ devised high-precision collet chuck for multiple applications including milling, drilling, reaming, and tapping, while maintaining runout accuracies of 0.003 mm (0.0001 inches) at 3xD. Manufacturers of many high-precision components in industries such as aerospace, transportation, die and mold, are now benifitting between producing high-tolerance parts with the production capability of higher tensile work-piece and coping with reality of future prospect as well.

Aerospace, die/mold and many other industries regularly encounter high-strength, difficult-to-machine materials requiring high torques, feeds, and forces. Hence, the danger of milling cutters being pulled out of the tool holder as the extreme forces has significantly increased. This is at least true for tool holders that offer precision clamping with good concentricity such as shrink-fit. Such toolholders work with frictional locking, but their clamping force is often not sufficient for roughing and

The new WIDIA universal precision collet is available with Safe-Lock pull-out protection from Haimer. Helical grooves are ground into the shank of the milling tool that, together with the respective pin drivers in the chuck, prevent the tool from spinning or being pulled out of the holder altogether under extreme machining conditions. The helical path of the Safe-Lock grooves also allows for adjusting tool length, meaning tools can be reground and pre-set as usual. WDIA collet chuck solution upgrades fabricator's performance and final part tolerance as well as working faster and save working hours.

The WIDIA™ High-Precision Collet Chuck Series features:

- Added versatility with the ability to continue using standard ER collets while upgrading to precision collets. This advantages are essential in economizing cost in tools procurement.

- Thicker chuck walls and a stronger outer form for added rigidity and lower vibration for longer spindle and tool life.

- A unique sealed-by-design precision collets (6 – 20 mm or 0.24 – 0.79 inches) for excellent coolant delivery and longer tool life.

- Improved clamping designs allows for better and repeatable balancing, all contributing to higher accuracy.

- Suitable for fully autonomous operation as the sturdy designs are sufficient in securing workpiece of high-strenght material.

- PDF catalog on metric can be downloaded here and on inches here

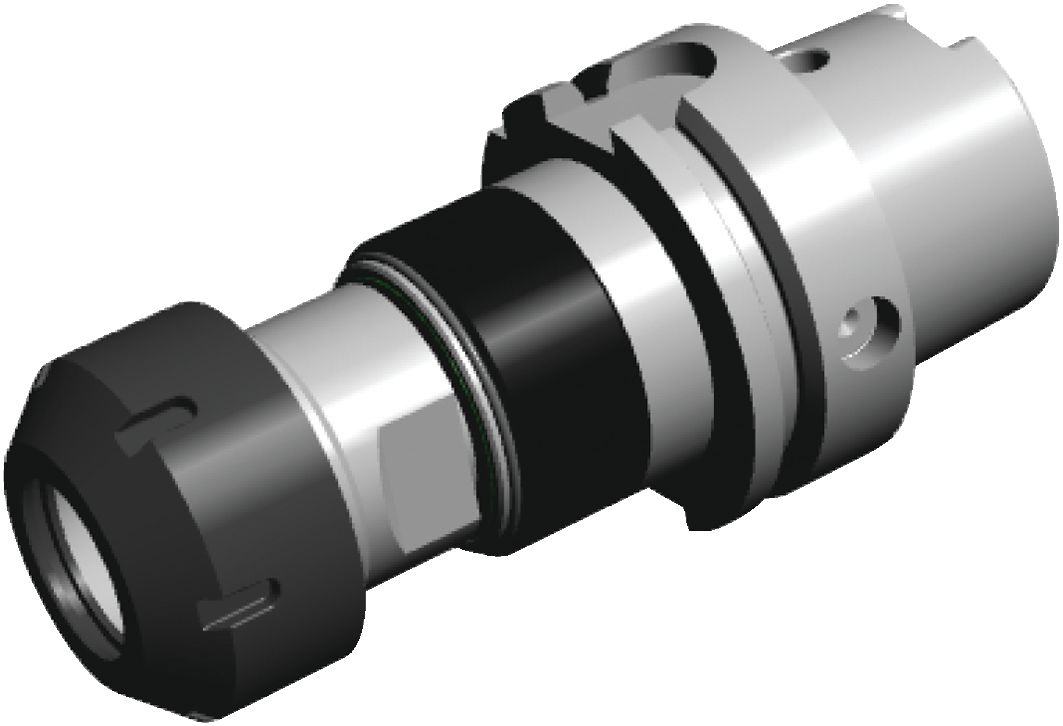

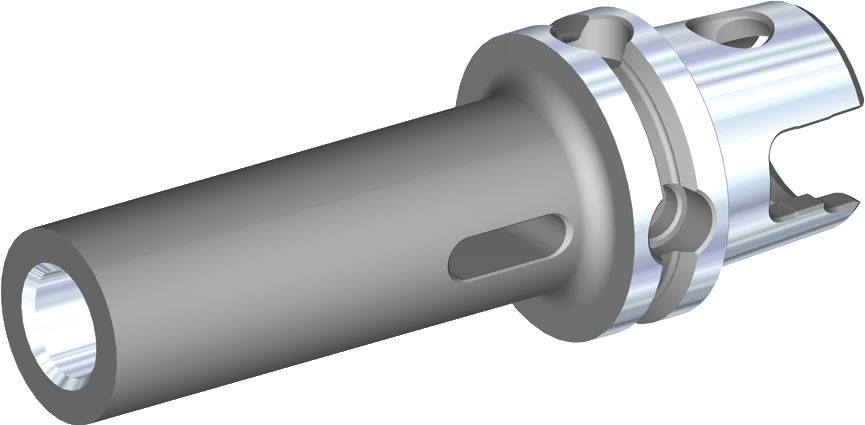

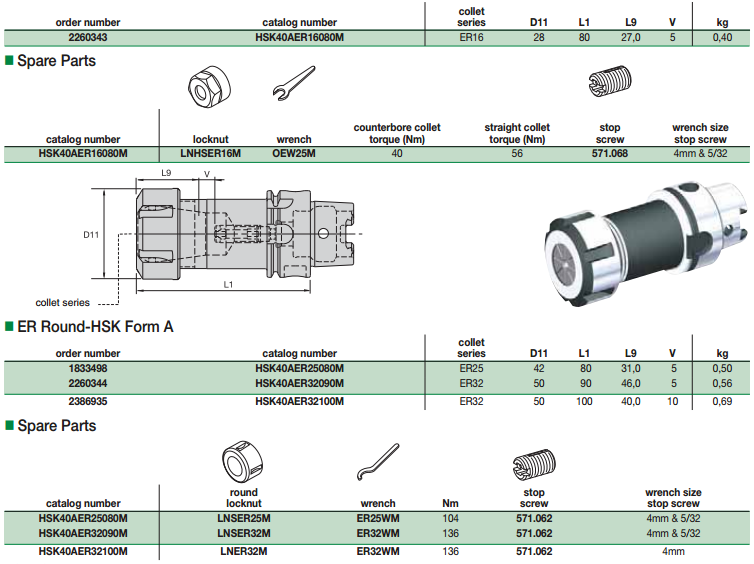

TECHNICAL SPECIFICATION

WIDIA™ Erickson™ HSK Series

The HSK40A tools are either prebalanced to a high specification or balanced-by-design and will perform effectively up to 15,000 RPM. For applications higher then 15,000 RPM, WIDIA™ recommends that the complete toolholder assembly (toolholder, coolant tubes, collets, hardware, and cutting tools) be balanced as one identity

WIDIA™ is a subsidiary company of Kennametal which specialize on manufacturing ultimate values of specific cutting and milling solution in Europe and India.

WIDIA™ manufactures bar peeling toolholders, tool heads, inserts, and accessories for all your bar peeling needs.

Request a Quote

Request A Quote

Please complete the below form to receive further information.