- Home

- Products

- Cutting Tools

- Face Mill

- WIDIA Victory™ Face mills insert

If you want to find out more about

WIDIA Victory™ Face mills insert

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

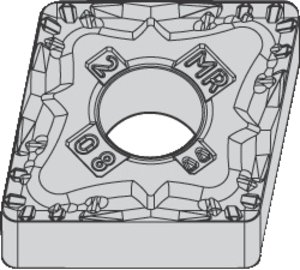

WIDIA™ brand inserts for the very popular and successful WIDIA Victory M1200™ face mill series are especially designed to provide excellent results in aluminum when machining the most common milling operations like roughing, semi-finishing, and finishing. Two separate geometries are being offered, and any shop milling aluminum and non-ferrous materials will benefit from using these two inserts in conjunction with the WIDIA Victory M1200 milling cutters. Their combination of toughness and wear resistance allow faster feed rates, and the 12 cutting edges per insert, as well as the reduced power consumption resulting from the free-cutting geometry, make them very economical to use. They are ideally suited for the majority of machining centers in use today using moderate to high spindle speeds and regular depths of cut (up to 4.5mm or 0.180 inch). The LDJ geometry featuring optimized rake angles is specifically designed to be free-cutting. This insert with 12 cutting edges is available in two grades, THMU and a TiB2-coated TN6501. Both inserts are peripherally ground and feature highly polished rake surfaces. THMU is the first choice for most non-ferrous materials while the TN6501 with its TiB2 coating offers even freer cutting in high silicon aluminum (>8%) due to the coating’s extremely low coefficient of friction. The LDJ3W geometry is a wiper-style geometry where excellent surface finish is required. It features 3 RH cutting edges and 3 LH cutting edges and is offered in the THMU and TN6501 grades also. Both the LDJ and LDJ3W inserts are extremely tough, wear resistant, and durable. They resist built-up edge, reduce burring, and increase surface finish results. WIDIA's Victory™ Insert Series features: Up to 30% longer tool life due to improved wear resistance. Get longer insert durability due to improved coating adhesion and edge toughness. The Right Insert for All of Your Turning Needs. Shorter cycle times because of increased speed and feed capabilities improves higher productivity and efficiency. Confidently select the right grade every time due to insert color code enables better wear detection for indexing. Get better Insert utilization due to the zirconium top layer with better surface finishes due to reduced friction and microchipping. Complete portfolio for steel, stainless steel, cast iron turning and Inserts for every application from roughing to fine finishing PDF catalog on metric can be downloaded here and on inches here

WIDIA™ brand inserts for the very popular and successful WIDIA Victory M1200™ face mill series are especially designed to provide excellent results in aluminum when machining the most common milling operations like roughing, semi-finishing, and finishing.

Two separate geometries are being offered, and any shop milling aluminum and non-ferrous materials will benefit from using these two inserts in conjunction with the WIDIA Victory M1200 milling cutters. Their combination of toughness and wear resistance allow faster feed rates, and the 12 cutting edges per insert, as well as the reduced power consumption resulting from the free-cutting geometry, make them very economical to use. They are ideally suited for the majority of machining centers in use today using moderate to high spindle speeds and regular depths of cut (up to 4.5mm or 0.180 inch).

The LDJ geometry featuring optimized rake angles is specifically designed to be free-cutting. This insert with 12 cutting edges is available in two grades, THMU and a TiB2-coated TN6501. Both inserts are peripherally ground and feature highly polished rake surfaces. THMU is the first choice for most non-ferrous materials while the TN6501 with its TiB2 coating offers even freer cutting in high silicon aluminum (>8%) due to the coating’s extremely low coefficient of friction.

The LDJ3W geometry is a wiper-style geometry where excellent surface finish is required. It features 3 RH cutting edges and 3 LH cutting edges and is offered in the THMU and TN6501 grades also. Both the LDJ and LDJ3W inserts are extremely tough, wear resistant, and durable. They resist built-up edge, reduce burring, and increase surface finish results.

Two separate geometries are being offered, and any shop milling aluminum and non-ferrous materials will benefit from using these two inserts in conjunction with the WIDIA Victory M1200 milling cutters. Their combination of toughness and wear resistance allow faster feed rates, and the 12 cutting edges per insert, as well as the reduced power consumption resulting from the free-cutting geometry, make them very economical to use. They are ideally suited for the majority of machining centers in use today using moderate to high spindle speeds and regular depths of cut (up to 4.5mm or 0.180 inch).

The LDJ geometry featuring optimized rake angles is specifically designed to be free-cutting. This insert with 12 cutting edges is available in two grades, THMU and a TiB2-coated TN6501. Both inserts are peripherally ground and feature highly polished rake surfaces. THMU is the first choice for most non-ferrous materials while the TN6501 with its TiB2 coating offers even freer cutting in high silicon aluminum (>8%) due to the coating’s extremely low coefficient of friction.

The LDJ3W geometry is a wiper-style geometry where excellent surface finish is required. It features 3 RH cutting edges and 3 LH cutting edges and is offered in the THMU and TN6501 grades also. Both the LDJ and LDJ3W inserts are extremely tough, wear resistant, and durable. They resist built-up edge, reduce burring, and increase surface finish results.

WIDIA's Victory™ Insert Series features:

- Up to 30% longer tool life due to improved wear resistance.

- Get longer insert durability due to improved coating adhesion and edge toughness. The Right Insert for All of Your Turning Needs.

- Shorter cycle times because of increased speed and feed capabilities improves higher productivity and efficiency.

- Confidently select the right grade every time due to insert color code enables better wear detection for indexing.

- Get better Insert utilization due to the zirconium top layer with better surface finishes due to reduced friction and microchipping.

- Complete portfolio for steel, stainless steel, cast iron turning and Inserts for every application from roughing to fine finishing

- PDF catalog on metric can be downloaded here and on inches here

TECHNICAL SPECIFICATION

WIDIA's Victory™ Insert Series

Selection Guidance for WIDIA's The carbide coating grade are as follows:

|

TN5515 Coated carbide grade TN5515 has an MT-CVD-TiN-TiCN-Al203 coating. Engineered for a balanced toughness and wear ratio. Ideal for light to medium machining of all cast irons. TN6510 Coated carbide grade TN6510 has a PVD-TiAlN multilayer. It performs well in light to medium machining of all cast irons. TN6520 Grade TN6520 has a PVD-TiAlN multilayer. It is engineeered for light and medium machining of all types of cast irons. TN6525 Carbide grade TN6525 has aPVD-TiAlN multilayer. It is ideal for light and medium machining applications in steels and high-strength nodular cast irons. TN6540 Coated carbide grade TN6540 has a PVD-TiAlN multilayer and is excellent for medium and heavy machining applications. It is ideal for use in all steels and nodular cast irons. |

|

Detailed WIDIA's insert catalog are available for download here

Request a Quote

Request A Quote

Please complete the below form to receive further information.