- Home

- Products

- Cutting Tools

- End Mills / Slot Drill

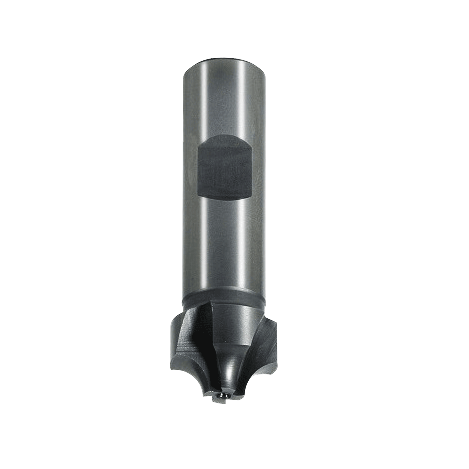

- Widia Solid Carbide End Mills 1 Flute 524149

If you want to find out more about

Widia Solid Carbide End Mills 1 Flute 524149

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Solid End Mills/High-Performance Solid Carbide End Mills/H/P Solid Carbide • Aluminum/Metric/List 524149 Widia Solid Carbide End Mills are made of Widia patented micro-grain carbide which produces higher toughness, hardness, and bending strength. Widia is now capable of combining the manufacturing prowess of Widia's typical HSS-Cobalt with the most up-to-date coating technology of aluminum titanium nitride (AlTiN; for aluminum contents higher than 50 at.%). The innovative combination stands for a group of metastable hard coatings consisting of the metallic elements aluminum and titanium, and nitrogen for your stability and wears resistance with a higher surface quality of the material to be machined. WIDIA™ Victory™ is the new benchmark for High-Performance Solid End Milling, giving you a solid performance advantage. Thanks to the combination of the highest concentricity accuracy and multi-layered coating on the shank, you can have increased oxidation resistance at elevated temperatures due to the formation of a protective aluminum-oxide layer at the surface. Your investment in Widia Solid Carbide End Mills will allow you to take on various jobs of slotting, peripheral, ramping, plunging, helical interpolation, or high-speed machining. With the smarter application of cutting parameters and reliable machinery, you can work Fine-finishing, finishing, rough finishing, and rough with the same tool with Different spiral angles (35°–38°). Widia Solid Carbide End Mills Series 524149 Features: Optimized for Aluminum, composite structures such as High-density polyethylene (HDPE) or polyethylene high-density (PEHD). Available size from ⌀3mm t0 12mm with material grade K10F-DCL Single flutes with a helical angle of 30° for improved edge strength and stability with a better surface finish Suitable for all-round slotting, peripheral, ramping, plunging, helical interpolation, or high-speed machining Corner style with square ends, suitable for ramping on blank surfaces, slotting, and radial cutting. Increased oxidation resistance at elevated temperatures due to coating technology of aluminum titanium nitride (AlTiN; for aluminum contents higher than 50 at.%) at the surface Longer tool life than regular model (> 30%) Significantly reduced part costs due to higher surface quality, stability, and process security

Solid End MillsHigh-Performance Solid Carbide End MillsH/P Solid Carbide • AluminumMetricList 524149

Widia Solid Carbide End Mills are made of Widia patented micro-grain carbide which produces higher toughness, hardness, and bending strength. Widia is now capable of combining the manufacturing prowess of Widia's typical HSS-Cobalt with the most up-to-date coating technology of aluminum titanium nitride (AlTiN; for aluminum contents higher than 50 at.%). The innovative combination stands for a group of metastable hard coatings consisting of the metallic elements aluminum and titanium, and nitrogen for your stability and wears resistance with a higher surface quality of the material to be machined.

WIDIA™ Victory™ is the new benchmark for High-Performance Solid End Milling, giving you a solid performance advantage. Thanks to the combination of the highest concentricity accuracy and multi-layered coating on the shank, you can have increased oxidation resistance at elevated temperatures due to the formation of a protective aluminum-oxide layer at the surface.

Your investment in Widia Solid Carbide End Mills will allow you to take on various jobs of slotting, peripheral, ramping, plunging, helical interpolation, or high-speed machining. With the smarter application of cutting parameters and reliable machinery, you can work Fine-finishing, finishing, rough finishing, and rough with the same tool with Different spiral angles (35°–38°).

Widia Solid Carbide End Mills Series 524149 Features:

- Optimized for Aluminum, composite structures such as High-density polyethylene (HDPE) or polyethylene high-density (PEHD).

- Available size from ⌀3mm t0 12mm with material grade K10F-DCL

- Single flutes with a helical angle of 30° for improved edge strength and stability with a better surface finish

- Suitable for all-round slotting, peripheral, ramping, plunging, helical interpolation, or high-speed machining

- Corner style with square ends, suitable for ramping on blank surfaces, slotting, and radial cutting.

- Increased oxidation resistance at elevated temperatures due to coating technology of aluminum titanium nitride (AlTiN; for aluminum contents higher than 50 at.%) at the surface

- Longer tool life than regular model (> 30%)

- Significantly reduced part costs due to higher surface quality, stability, and process security

TECHNICAL SPECIFICATION

Widia Solid Carbide End Mills Ordering Guide:

| order number | K10F-DCL | Adapter Style Machine Side | D1 | D | length of cut Ap1 max | length L |

| 2651100 » | 524149-000030 | Straight-Cylindrical | 3,0 | 6 | 12,00 | 50 |

| 2651314 » | 524149-000040 | Straight-Cylindrical | 4,0 | 6 | 15,00 | 60 |

| 2651317 » | 524149-000050 | Straight-Cylindrical | 5,0 | 6 | 17,00 | 60 |

| 2651318 » | 524149-000060 | Straight-Cylindrical | 6,0 | 6 | 20,00 | 60 |

| 2651319 » | 524149-000080 | Straight-Cylindrical | 8,0 | 10 | 25,00 | 75 |

| 2651320 » | 524149-000100 | Straight-Cylindrical | 10,0 | 8 | 25,00 | 75 |

| 2651321 » | 524149-000120 | Straight-Cylindrical | 12,0 | 12 | 25,00 | 75 |

|

NOTE: Lower value of cutting speed is used for high stock removal applications or for higher hardness (machinability) within group. Higher value of cutting speed is used for finishing applications or for lower hardness (machinability) within group. Above parameters are based on ideal conditions. |

Widia Solid Carbide End Mills 1 Flute 524149 Tolerance of cut:

| End Mill Tolerances | |||

| D1 | tolerance h10 + / - | D | tolerance h6 + / - |

| ≤ 3 | 0/0,040 | ≤ 3 | 0/0,006 |

| > 3–6 | 0/0,048 | > 3–6 | 0/0,008 |

| > 6–10 | 0/0,058 | > 6–10 | 0/0,009 |

| > 10–18 | 0/0,070 | > 10–18 | 0/0,011 |

| > 18–30 | 0/0,084 | > 18–30 | 0/0,013 |

Request a Quote

Request A Quote

Please complete the below form to receive further information.