What is a Connecting Rod?

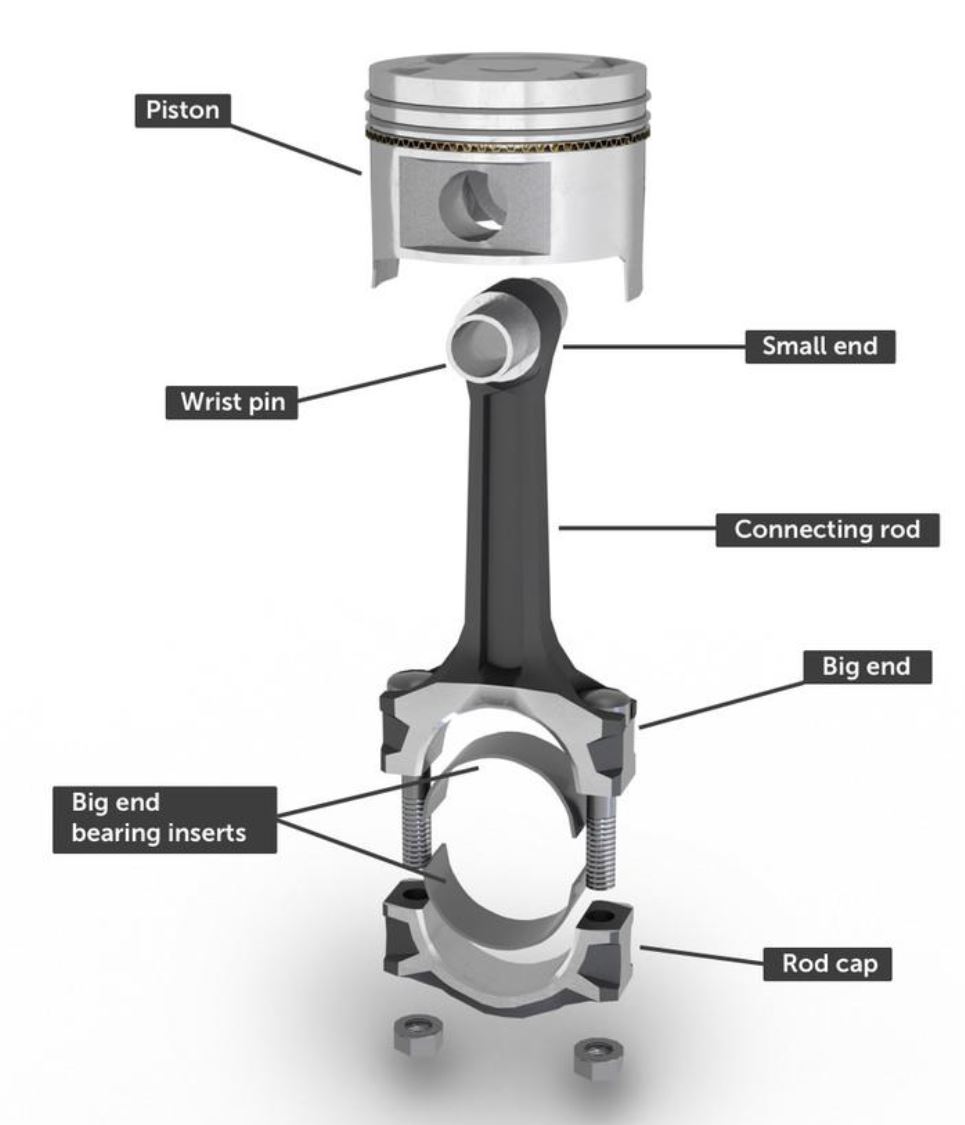

A connecting rod is also known as a conrod for short. Conrods are commonly found in internal combustion engines. A connecting rod for an internal combustion engine consists of the 'big end', 'rod' and 'small end'. The small end attaches itself to the gudgeon pin, which can swivel in the piston. Typically, the big end connects to the crankpin using a plain bearing to reduce friction.

Usually there is a pinhole bored through the bearing on the big end of the connecting rod so that lubricating oil squirts out onto the thrust side of the cylinder wall to lubricate the travel of the pistons and piston rings.

A connecting rod can rotate at both ends, so that the angle between the connecting rod and the piston can change as the rod moves up and down and rotates around the crankshaft. A connecting rod is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end.

Why Measure Conrods with Air Gauging?

Measuring connecting rods is not straightforward and takes time. This is especially so if the measurements are carried out on a CMM (Coordinate-measuring Machine). Hence, in the interest of time, our solution is based on air measurement.

As mentioned in our earlier article, the air gauge can be used to do a combination of measurements. It is suitable to be used for measuring parts at multiple points and dimensions. This is because air gauges can be designed into a jig to measure complex geometric tolerance, like the conrods in this instance. This can be achieved by using displays with multiple channels.

Furthermore, the air gauge is useful for measuring conrods due to its ease of use, the operator will not be required to be specially trained to use the equipment. This is unlike the CMM which requires a learning curve to operate. It is also highly accurate and repeatable. It is also possible to measure the parts without cleaning them first, which makes it suitable for conrod measurement.

Solution

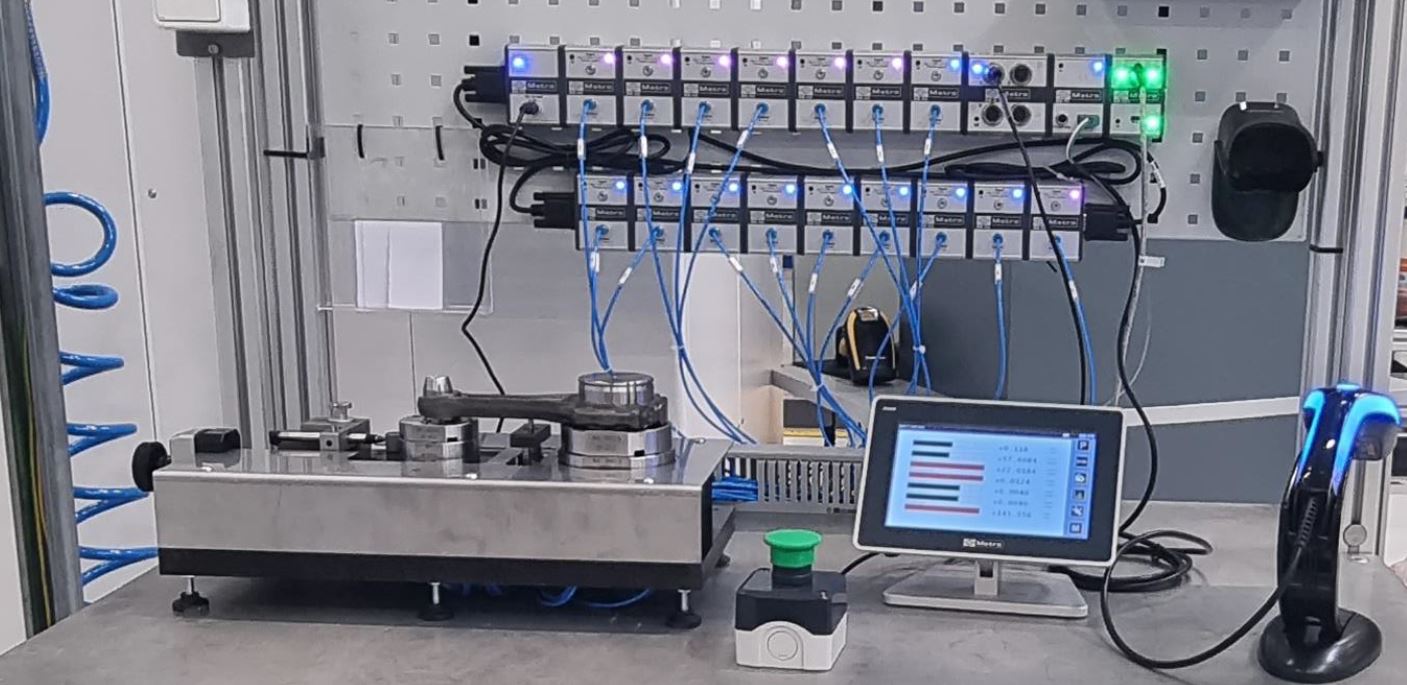

In this example here, what we want to achieve is to have a flexible control station. It should be able to measure 25 different types of conrods by air and probe in just a few seconds. The part number and other information will be introduced by the barcode scanner. Temperature compensation is also taken into account by using a K type probe. The measurement data will also need to be exported to the server after the measurement is taken.

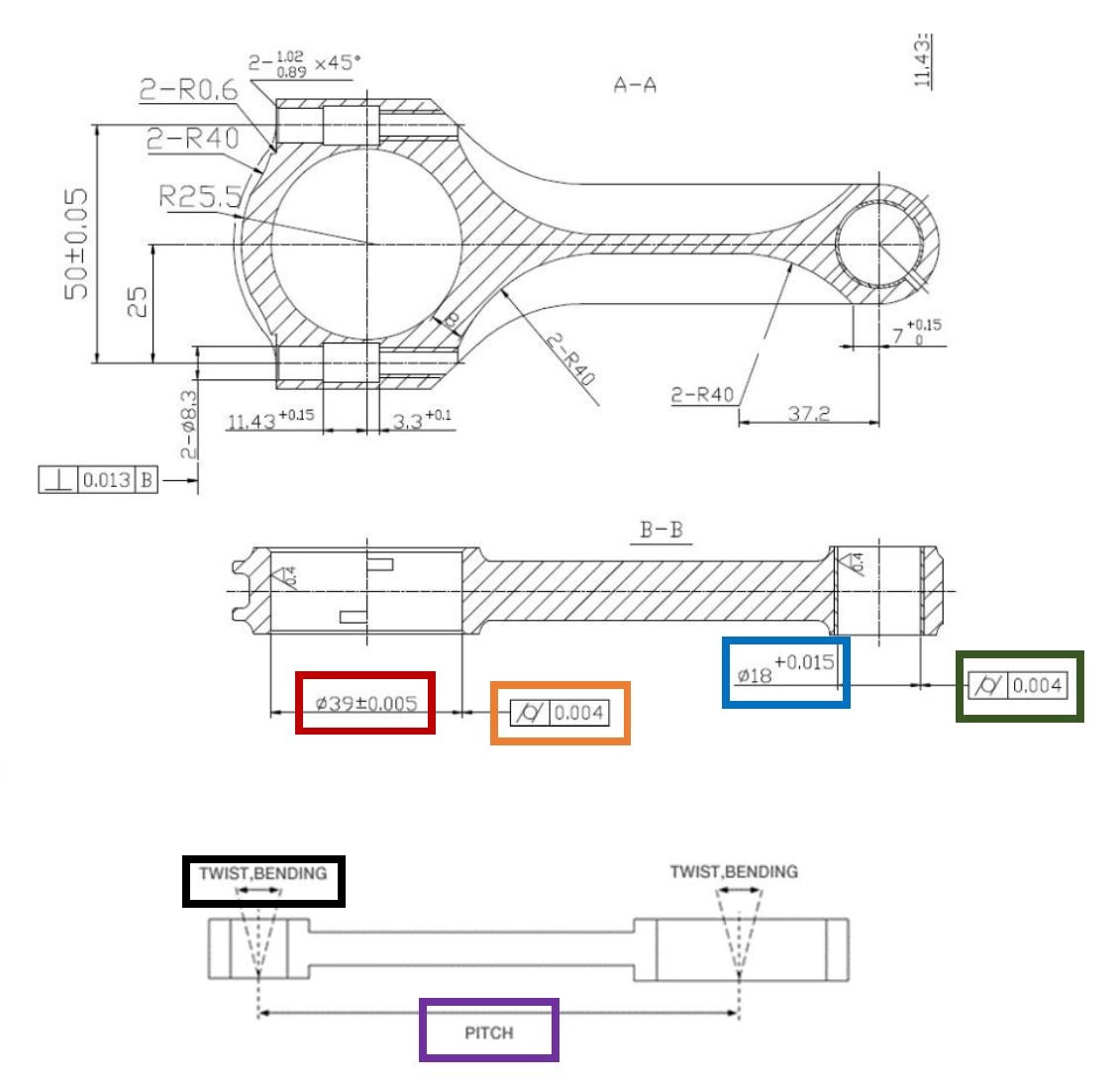

Here’s the list of measurements that will be done using air gauges:

- Diameter of the small end at 2 different levels

- Parallelism of the small end diameter

- Diameter of the big end at 2 different levels

- Parallelism of the small end diameter

- Bend of the small end compared to the big end

- Twist of the small end compared to the big end

The centreline distance (pitch) between the small and big ends will be measured by probe in this example.

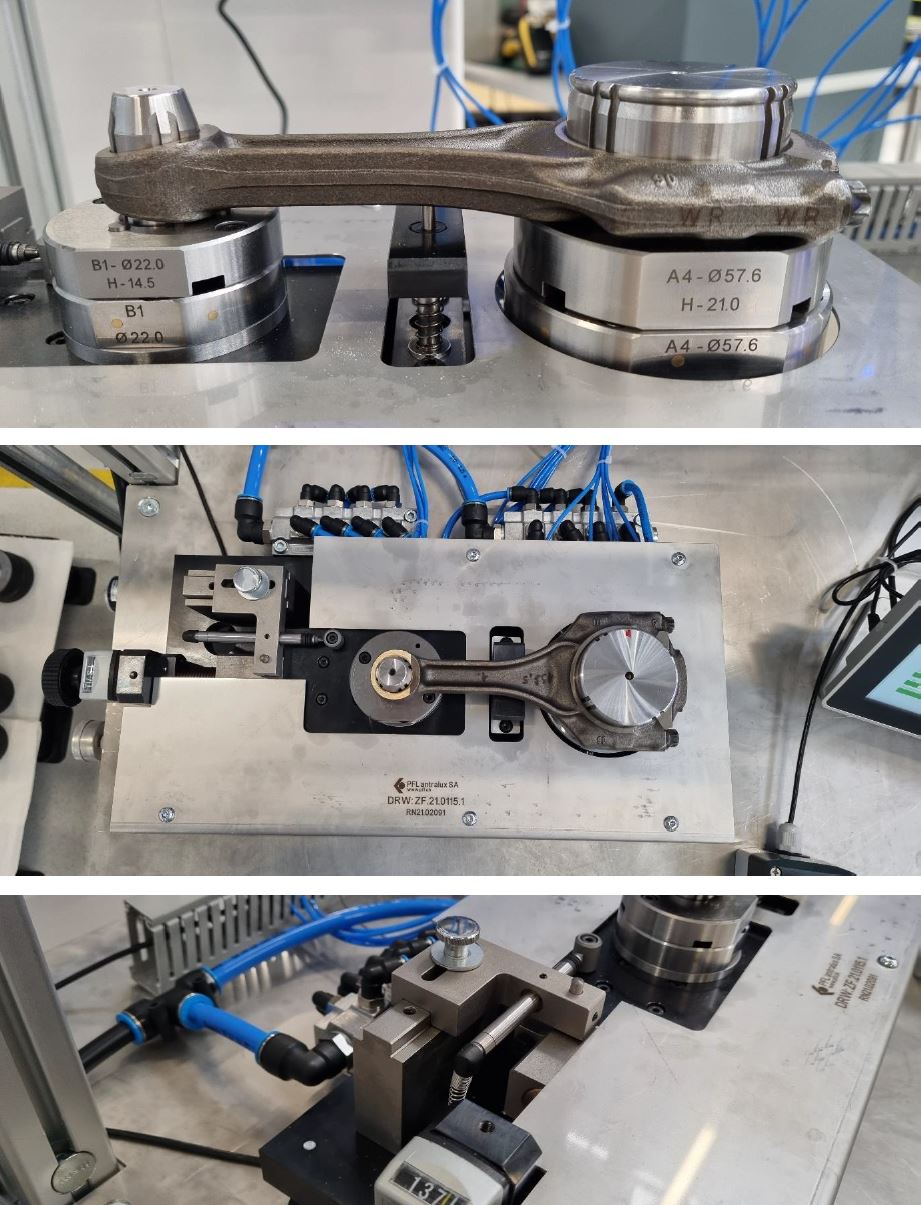

A custom measuring jig is fabricated as follows:

- Air plug gauges for small and big ends can be easily changed according to diameters and thickness.

- A complete set of air plug gauges covering the 25 different types of connecting rods has been delivered with the jig.

- Air plug gauge for the big end is mounted on a movable element to cover different centreline distances

Here is the list of measuring equipment used to build the conrod measuring station:

| Part Number | Qty | Description |

| 804.2400 | 1 | Sylvac Display unit D400S |

| 804.2105 | 1 | M_Bus 4i inductive probes module |

| 804.2170 | 1 | M_Bus TP temperature module |

| 804.2190 | 16 | M_Bus AG air module |

| 804-xxxx | 1 | M_Bus NET network (server) connection module |

| 804.223 | 1 | Air preparation kit |

| 900.1111 | 1 | Probe P5i |

| 925.5609 | 2 | RS Cable |

These are additional equipments that were used:

- Barcode scanner

- External switch

- Temperature sensor type K

In this example, the D400S played an important role in the measuring station as it provided many advantages. Firstly, we were able to have a simultaneous display of the dimensions being measured in one screen. All the configurations corresponding to the different types of conrods (25 different types in this instance) could be saved in the D400S. We were also able to connect a barcode scanner to introduce information to the D400S. We were also able to activate the temperature compensation with the use of an M_Bus TP temperature module. The D400S could also take care of the statistical analysis required and export the data to the user's server.

If you are looking to measure with air gauges or trying to set up an air gauge station. Contact us for a discussion. We always look forward to solving measurement problems together with you. We have also written an article on how you can measure your workpieces with air gauges previously. You can click on this link to read all about it. Sylvac develops, designs and manufactures digital measuring systems and instruments for industrial use. Drawing on a resourceful mix of expertise in electronics, mechanics and metrology, their high-precision products are renowned for innovation and highly prized Swiss quality. LFC is proud to be the exclusive distributor for Sylvac in Singapore. Talk to us if you are looking to digitally transform your quality control instruments.

References

-

Wikimedia Foundation. (2021, September 2). Connecting rod. Wikipedia. https://en.wikipedia.org/wiki/Connecting_rod.