- Home

- Products

- Bandsaw Machines

- Straight-Cutting

- Behringer High-Performance Automatic Bandsaws HBM440ALU

If you want to find out more about

Behringer High-Performance Automatic Bandsaws HBM440ALU

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

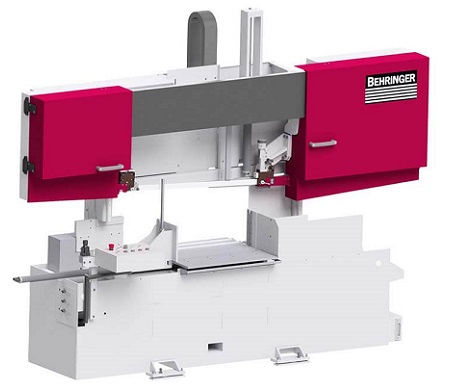

Behringer High-Performance Automatic Bandsaws HBM440ALU Unbeatable speed – even with the toughest jobs When it comes to cutting output, automation, and process reliability in the steel trade and production, nothing beats the Behringer High-Performance Automatic Bandsaws HBM440ALU. These high-performance automatic bandsaw machines are designed to meet the most demanding requirements and offer an impressive package of benefits. Whether you're working with non-ferrous metals, aluminum, steel, Inconel, or titanium, the HBM series bandsaw machines deliver unbeatable speed and precision. With its exceptional cutting performance, precision, and reliability, the Behringer High-Performance Automatic Bandsaws HBM440ALU ensures that you can tackle even the toughest jobs with ease. From large-scale steel production to smaller metalworking projects, the Behringer High-Performance Automatic Bandsaws HBM440ALU is the go-to solution for professionals in the industry. Sawing aluminum and non-ferrous metals economically The HBM ALU series is specially designed for sawing ingots and billets made of aluminum or comparable non-ferrous metals such as magnesium. They cut quickly, reliably, precisely, and with a small kerf, thus contributing to future-proof, resource-saving production. The HBM ALU series can be designed to suit the application, from simple automatic machines with chip conveyors to automated, interlinked saw cells with integrated chip extraction. Here are some features of Behringer High-Performance Automatic Bandsaws HBM440ALU, including: Speed-Cutting Technology The high-performance sawing unit can be fitted with the Behringer Speed-Cutting technology as an option. The combination of Speed-Cutting saw blade guides, a high-performance cooling system, a dynamically controlled saw feed and specially optimized Auto-Feed-Control allows you to get the maximum performance and tool life. Cast Iron Bandsaw Guide Manufactured by Behringer, the band guide provides a vibration-damping effect. It directly reduces vibration at the edge where the material is cut. As a result, the bandsaw blade tool life is increased. Servo Downfeed System The saw feed is carried out by means of a ball screw and servo motor with cutting pressure control. This results in significantly shorter idle times and more precise saw feeds. Your advantage: higher cutting performance and longer bandsaw blade tool life. Roller Band Guide with High-Performance Cooling Roller band guides ensure precise guidance of the saw band even at extremely high blade speeds. For a long service life, the bearings of the rollers are centrally lubricated by an automatic lubrication system, integrated into the bandsaw machine. Micro Spray System for process-safe lubrication of the saw band with spray oil. Due to the special arrangement of the spray nozzles, the saw band is reliably moistened even at high speed. Economical Use of Carbide Saw Blades Achieve the highest cutting performance when sawing with bimetal and carbide saw blades. This is made possible due to the robust design, the use of the latest servo technology, and well-dimensioned chip disposal. Chip Disposal Adapted to Application In the high-performance machining of aluminum and non-ferrous metals, massive quantities of chips are produced that must be removed reliably. Whether with a chip conveyor or connected to a central extraction system - the chip removal of the HBM series grows dynamically with your requirements. Other Features: Prepared for automation A powerful machine concept puts high demands on material handling. The high-performance bandsaws of the HBM series are often configured as automated sawing systems. Therefore, the machines are already prepared in the basic configuration for the connection of extensive material handling equipment. Precision Portal-Design Guide System The combination of a stable, low-vibration saw frame and the linear guide system in the portal design ensure the best cutting results and maximum service life. Automatic Guide Arm Optimum sawing result without any adjustments - even with frequently changing material sizes. LFC is the exclusive distributor of Behringer sawing machines in Singapore and Malaysia. The HBM440ALU can be configured perfectly to your requirements with numerous options. This is how you get the most out of your production. Our team will be pleased to advise you. Contact us for a discussion! LFC PTE LTD 8 Ubi Rd 2, #03-01, Zervex Singapore 408538 EMAIL sales@lfc.com.sg PHONE (65) 6749 9697

Behringer High-Performance Automatic Bandsaws HBM440ALU

Unbeatable speed – even with the toughest jobs

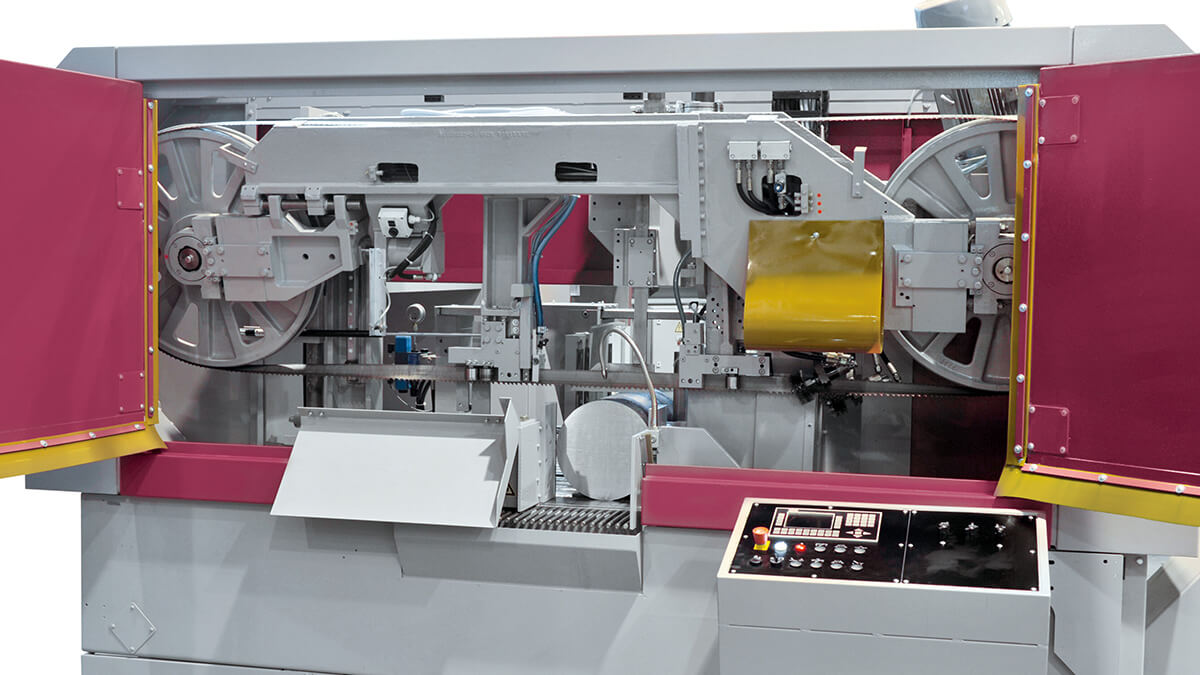

When it comes to cutting output, automation, and process reliability in the steel trade and production, nothing beats the Behringer High-Performance Automatic Bandsaws HBM440ALU. These high-performance automatic bandsaw machines are designed to meet the most demanding requirements and offer an impressive package of benefits. Whether you're working with non-ferrous metals, aluminum, steel, Inconel, or titanium, the HBM series bandsaw machines deliver unbeatable speed and precision. With its exceptional cutting performance, precision, and reliability, the Behringer High-Performance Automatic Bandsaws HBM440ALU ensures that you can tackle even the toughest jobs with ease. From large-scale steel production to smaller metalworking projects, the Behringer High-Performance Automatic Bandsaws HBM440ALU is the go-to solution for professionals in the industry.

Sawing aluminum and non-ferrous metals economically

The HBM ALU series is specially designed for sawing ingots and billets made of aluminum or comparable non-ferrous metals such as magnesium. They cut quickly, reliably, precisely, and with a small kerf, thus contributing to future-proof, resource-saving production. The HBM ALU series can be designed to suit the application, from simple automatic machines with chip conveyors to automated, interlinked saw cells with integrated chip extraction.

Here are some features of Behringer High-Performance Automatic Bandsaws HBM440ALU, including:

|

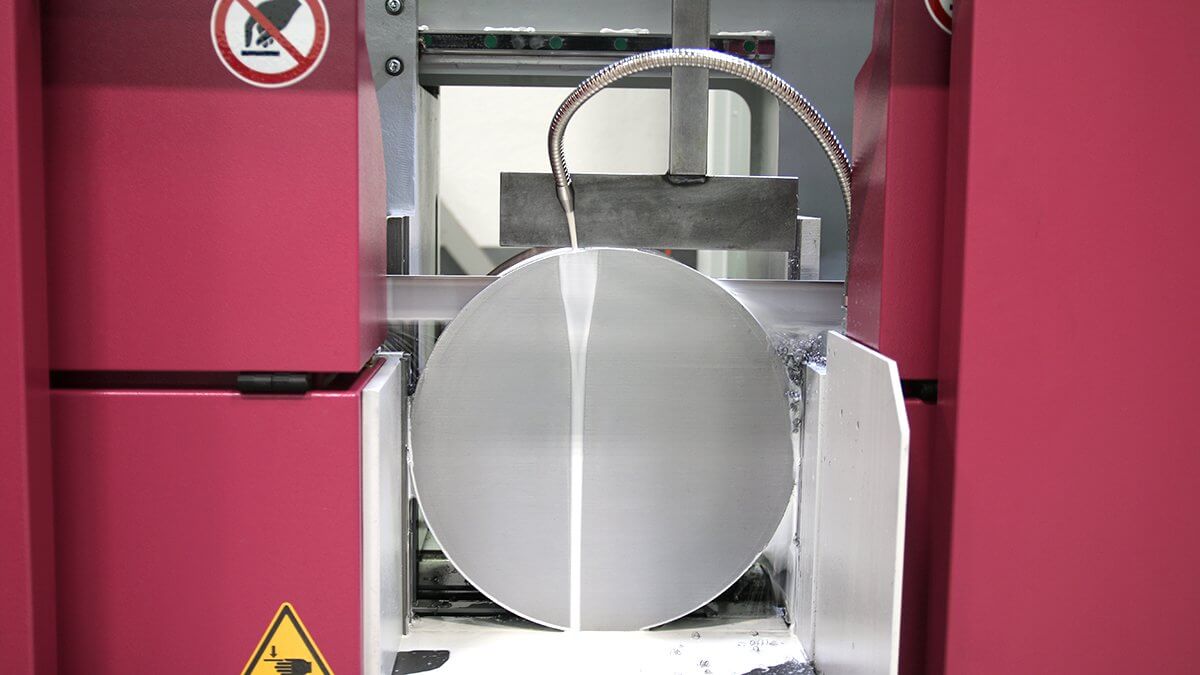

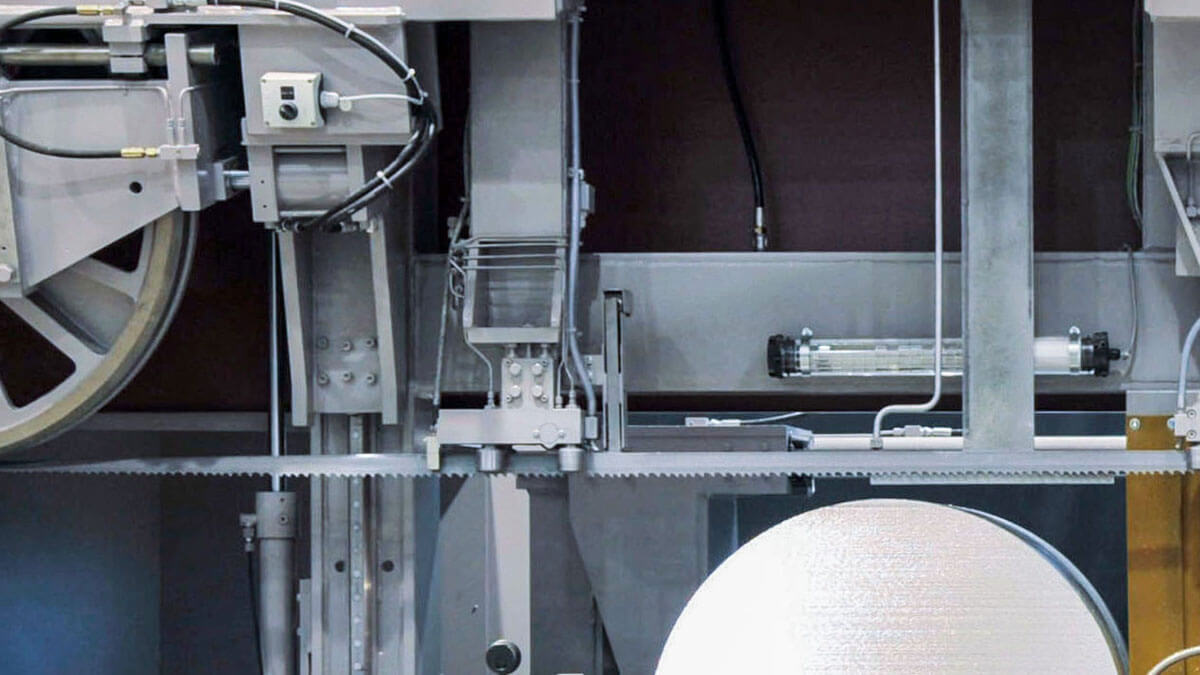

Speed-Cutting Technology The high-performance sawing unit can be fitted with the Behringer Speed-Cutting technology as an option. The combination of Speed-Cutting saw blade guides, a high-performance cooling system, a dynamically controlled saw feed and specially optimized Auto-Feed-Control allows you to get the maximum performance and tool life. |

|

|

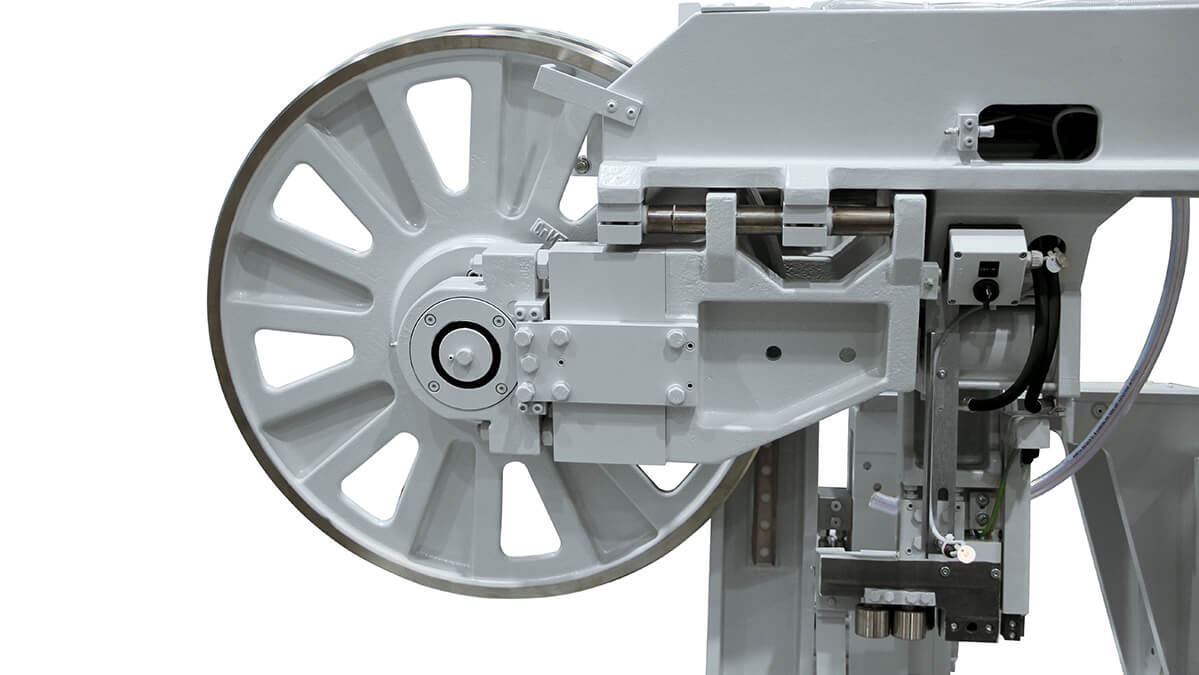

Cast Iron Bandsaw Guide Manufactured by Behringer, the band guide provides a vibration-damping effect. It directly reduces vibration at the edge where the material is cut. As a result, the bandsaw blade tool life is increased. |

|

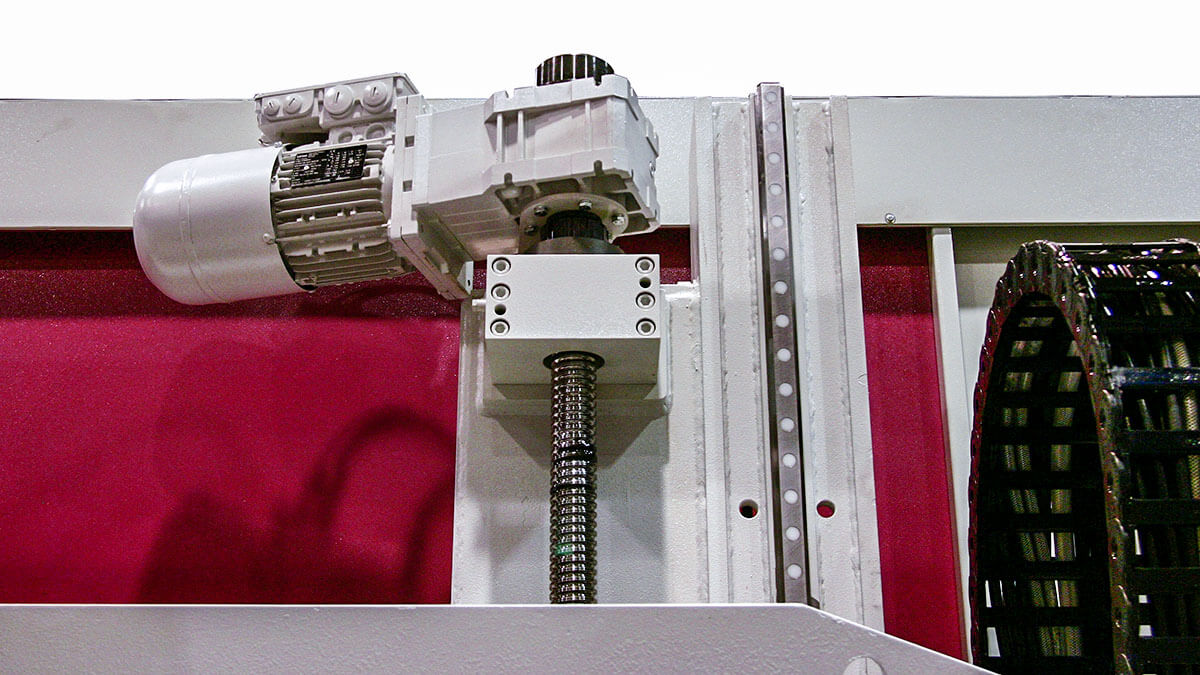

Servo Downfeed System The saw feed is carried out by means of a ball screw and servo motor with cutting pressure control. This results in significantly shorter idle times and more precise saw feeds. Your advantage: higher cutting performance and longer bandsaw blade tool life. |

|

|

Roller Band Guide with High-Performance Cooling Roller band guides ensure precise guidance of the saw band even at extremely high blade speeds. For a long service life, the bearings of the rollers are centrally lubricated by an automatic lubrication system, integrated into the bandsaw machine. Micro Spray System for process-safe lubrication of the saw band with spray oil. Due to the special arrangement of the spray nozzles, the saw band is reliably moistened even at high speed. |

|

Economical Use of Carbide Saw Blades Achieve the highest cutting performance when sawing with bimetal and carbide saw blades. This is made possible due to the robust design, the use of the latest servo technology, and well-dimensioned chip disposal. |

|

|

Chip Disposal Adapted to Application In the high-performance machining of aluminum and non-ferrous metals, massive quantities of chips are produced that must be removed reliably. Whether with a chip conveyor or connected to a central extraction system - the chip removal of the HBM series grows dynamically with your requirements. |

Other Features:

Prepared for automation

A powerful machine concept puts high demands on material handling. The high-performance bandsaws of the HBM series are often configured as automated sawing systems. Therefore, the machines are already prepared in the basic configuration for the connection of extensive material handling equipment.

Precision Portal-Design Guide System

The combination of a stable, low-vibration saw frame and the linear guide system in the portal design ensure the best cutting results and maximum service life.

Automatic Guide Arm

Optimum sawing result without any adjustments - even with frequently changing material sizes.

LFC is the exclusive distributor of Behringer sawing machines in Singapore and Malaysia. The HBM440ALU can be configured perfectly to your requirements with numerous options. This is how you get the most out of your production. Our team will be pleased to advise you. Contact us for a discussion!

Overview

TECHNICAL SPECIFICATION

| Cutting Range | |

| Cutting range 90° round | 440 mm |

| Cutting range 90° flat | 440 x 440 mm |

| Smallest dimension to be sawn round | 20 mm |

| Smallest dimension to be sawn flat | 20 x 15 mm |

| Performance Characteristics | |

| Feeding length single stroke | 600 mm |

| Drive Power | 22 kW |

| Blade Speed | 300 - 1300 m/min |

| Saw Blade Dimension | 7,200 x 34 x 1.1 mm |

| Rest piece length in automatic operation | 50 mm |

| Total power |

29 kW |

| Saw feed | servo-feed via ball screw |

| Material feed |

ball screw |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

| Dimension & Weight | |

| Length | 2,650 mm |

| Width | 4,385 mm |

| Height | 2,700 mm |

| Weight | 4,700 kg |

| Material support height | 800 mm |

Request a Quote

Request A Quote

Please complete the below form to receive further information.