- Home

- Products

- Limit Gauges

- Thread Gauges

- Ojiyas NPT Thread Plug Gauge

If you want to find out more about

Ojiyas NPT Thread Plug Gauge

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Ojiyas Gauges for ANSI Taper Pipe ThreadsGauges for ANSI taper pipe threads are used to inspect general sealable parts. Various gauge specifications are used, some of which have notches. Common thread plug and ring gauges have 3 step notches (L1). If the inspected taper thread conforms to the standard dimensions, the pipe end stops at the middle notch on the gauge. The other two notches are there to indicate the maximimum and minimum allowed dimensions. NPT National Pipe TaperTaper pipe threads (NPT) specified in American standard (ANSI) are used to connect pipes, plumbing parts, fluid equipments and etc. Their purpose is to increase the density resistance of the threaded parts. Ojiyas Gauges for taper pipe threads (NPT) are used for measuring dimension of such threads. NPTF National Pipe Taper Fuel and OilTaper pipe threads NPTF specified in American standard (ANSI) are meant for threads used to join ful or oil pipes in ships, automobiles, aircrafts and etc. These threads are designed to achieve dry seal joints without a sealing material. In NPTF threads, the density resistance of the thread parts can be obtained even without using seal compound. L1 plug and L1 ring are used to check the wrench-tight length (L3 and L2-L1) of external and internal threads. When the position of the notches of the two gauges, L1 and L3 plug, or L1 and L2 ring, tightens, it is not more than half a turn. The product's degree of taper is also guaranteed. WHY OJIYAS GAUGES? Precision Finishing Ojiyas (Ojiya Seiki Co., Ltd.) manufactures high quality thread gauge, measuring gauges and various inspection jigs. The company pursues a high level of precision manufacturing technologies and measurements to produce high quality products. Ojiyas products are widely used in various industries – automotive, aerospace, bicycle etc. Heat Treatment Ojiyas gauges undergo heat treatment to attain maximum hardness and increase its resistance to corrosion. Sub-Zero Treatment Sub-zero treatment of gauges changes the phase structure and improves the gauge’s quality and performance. Ojiyas gauges undergoes professional sub-zero treatment for better wear resistance & dimensional stability. You can find out more about the complete Ojiyas range of products by viewing the Ojiyas Catalog on our support page. LFC is the authorized distributor for Ojiyas in Singapore and Indonesia. Contact us if you wish to discuss your gauging applications further. LFC PTE LTD 8 Ubi Rd 2, #03-01, Zervex Singapore 408538 EMAIL sales@lfc.com.sg PHONE (65) 6749 9697

Ojiyas Gauges for ANSI Taper Pipe Threads

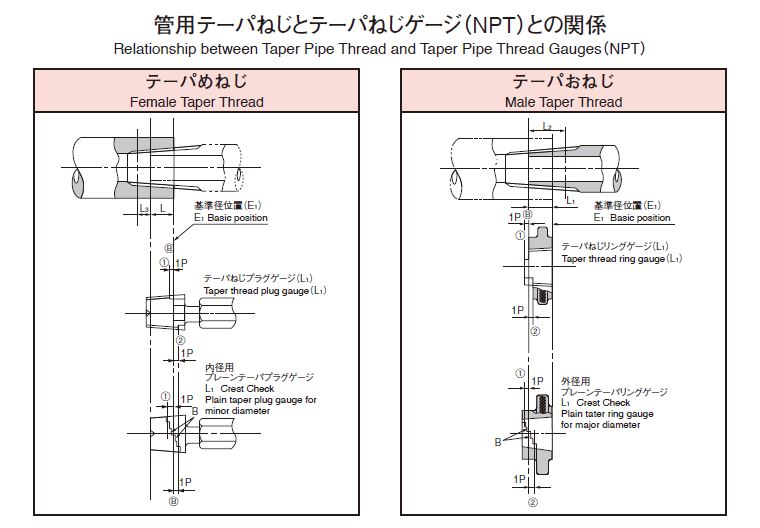

Gauges for ANSI taper pipe threads are used to inspect general sealable parts. Various gauge specifications are used, some of which have notches. Common thread plug and ring gauges have 3 step notches (L1). If the inspected taper thread conforms to the standard dimensions, the pipe end stops at the middle notch on the gauge. The other two notches are there to indicate the maximimum and minimum allowed dimensions.

NPT National Pipe Taper

Taper pipe threads (NPT) specified in American standard (ANSI) are used to connect pipes, plumbing parts, fluid equipments and etc. Their purpose is to increase the density resistance of the threaded parts. Ojiyas Gauges for taper pipe threads (NPT) are used for measuring dimension of such threads.

NPTF National Pipe Taper Fuel and Oil

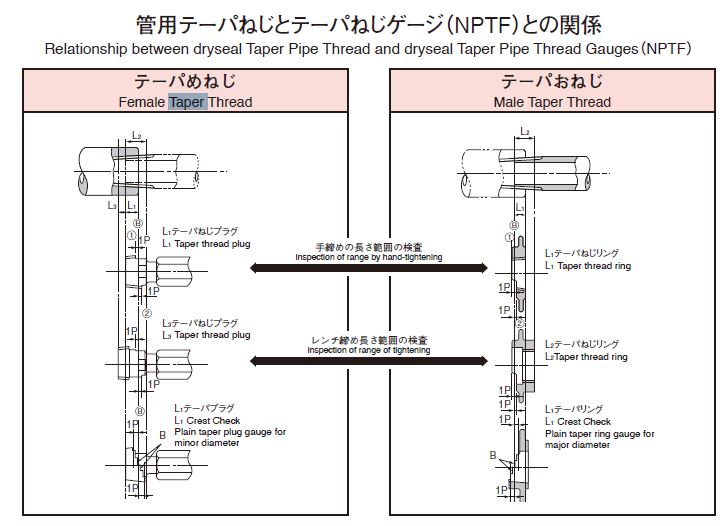

Taper pipe threads NPTF specified in American standard (ANSI) are meant for threads used to join ful or oil pipes in ships, automobiles, aircrafts and etc. These threads are designed to achieve dry seal joints without a sealing material. In NPTF threads, the density resistance of the thread parts can be obtained even without using seal compound. L1 plug and L1 ring are used to check the wrench-tight length (L3 and L2-L1) of external and internal threads. When the position of the notches of the two gauges, L1 and L3 plug, or L1 and L2 ring, tightens, it is not more than half a turn. The product's degree of taper is also guaranteed.

WHY OJIYAS GAUGES?

Precision Finishing

Ojiyas (Ojiya Seiki Co., Ltd.) manufactures high quality thread gauge, measuring gauges and various inspection jigs. The company pursues a high level of precision manufacturing technologies and measurements to produce high quality products. Ojiyas products are widely used in various industries – automotive, aerospace, bicycle etc.

Heat Treatment

Ojiyas gauges undergo heat treatment to attain maximum hardness and increase its resistance to corrosion.

Sub-Zero Treatment

Sub-zero treatment of gauges changes the phase structure and improves the gauge’s quality and performance. Ojiyas gauges undergoes professional sub-zero treatment for better wear resistance & dimensional stability.

You can find out more about the complete Ojiyas range of products by viewing the Ojiyas Catalog on our support page. LFC is the authorized distributor for Ojiyas in Singapore and Indonesia. Contact us if you wish to discuss your gauging applications further.

Overview

Built to last

Since 1966, OJIYA SEIKI is comitted towards devising the practical precision processing technologies which are durable and reliable. OJIYAS is the total solution towards precision measurement that will drive you to win the global competition.

Customer values

OJIYA SEIKI empower your fabrication quality control as the latest technology demands for compact machinery with ultimate precision. Every OJIYAS product are not only certified by the Japan quality assurance but also by the ISO9001:2000 on quality management and the ISO14001:2004 on environmental certification

TECHNICAL SPECIFICATION

Ojiyas Gauges for ANSI Taper Pipe Threads

There are many types of gauges for taper threads with various different notches. In general, the gauges for taper threads L1 having three notches, i.e., minimum limit position ①, basic position B and maximum limit position ②, are the most commonly used. The use of the taper thread gauges has been explained in the previous pages. However, since there is a specifi cation of truncation for major and minor diameters of thread height, it is recommended to measure major and minor diameters using plain taper gauges having 6-step notches. First, the pitch diameter of the taper thread is measured with a taper thread gauge. For example, when it is judged pass at near the notch of basic position B, then for major and minor diameters, is also similar. That is the item is judged pass when the pipes can go within limit range of B. For inspection of tight tolerances, taper thread plug L3 and taper thread ring L2 are used. Refer to the following page of NPTF type threads for the detail methods of inspection.

There are many types of taper thread gauges with various different notches. In general, the taper thread gauges L1 having three notches, i.e., minimum limit position ①, basic position B and maximum limit position ②, are the most commonly used. Similar to NPT type, it is recommended to measure major and minor diameters using plain taper gauge having 6-step notches. For inspection of thread of handtight engagement, taper thread plug gauge L1 and taper thread ring gauge L1 are used for measuring the female and male threads, respectively. For inspection of thread of wrench tolerances, taper thread plug gauge L3 and taper thread ring gauge L2 are used for female and male threads, respectively.

Request a Quote

Request A Quote

Please complete the below form to receive further information.