If you want to find out more about

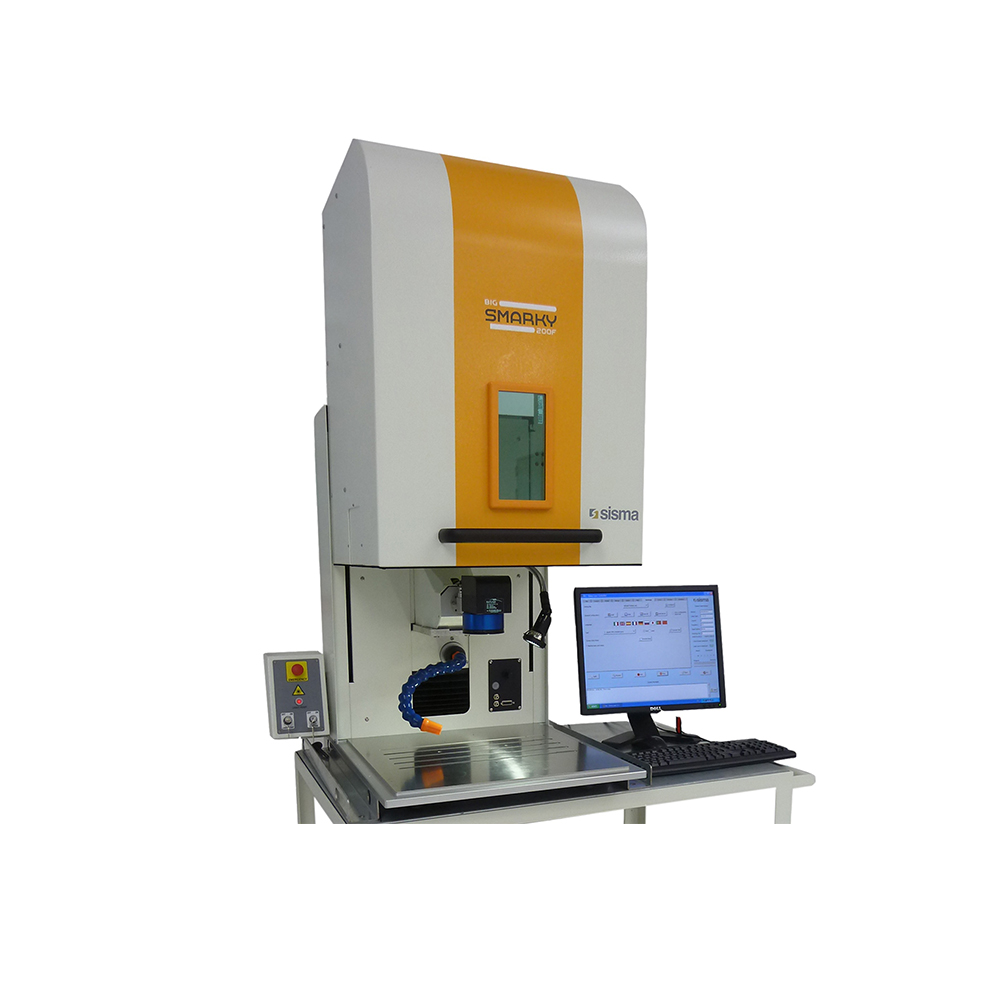

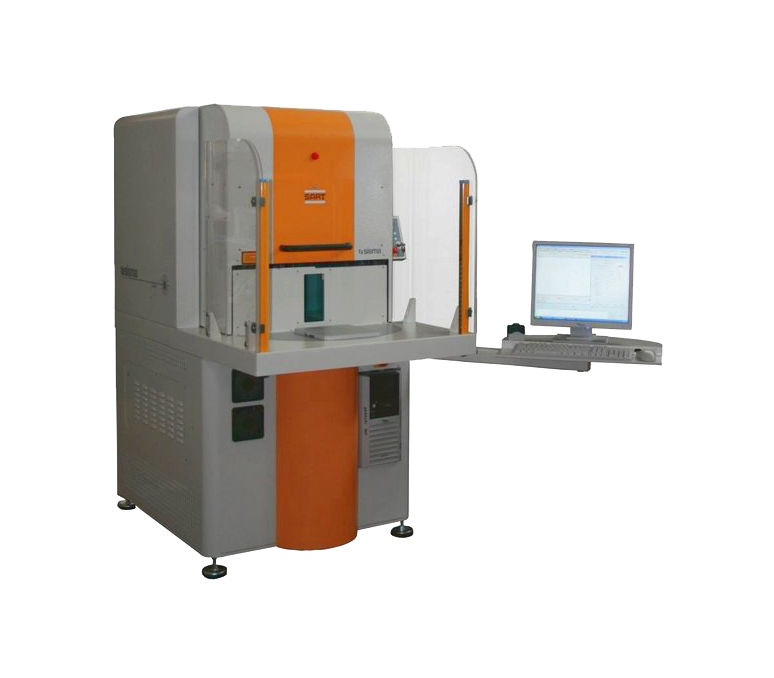

Sisma Laser Marking Smarky OEM Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Sisma OEM marking unit is the answer to your need of laser marking with slight depth engraving on all types of metallic material surface as in metalworking mould & dies, jewellery, solid material and hard composite plastic. You can easily which is easily configure the appropriate paraeter through Sisma's user friendly computer software. Sisma OEM's software are intuitive and fully compatible with all types of files like SVG, DXF, BMP, JPG even PLT formatted. From a simple batch plate signature on your products to creating and marking different types of data, bar codes and matrix data on your product's metal case, Sisma OEM can do it all. You can say goobye to the old chemical etching method, manual engraving, micro milling, rubber ball transfer stamp and transfer screen paint mesh which are messy and consistently requires skilled workers. The Sisma OEM marking machine itself is the only reasonable and economical investment in terms of seamless marking details, accuracy and user friendly software. Thanks to its class IV laser source level, you can have a concentrated heat source with narrower and faster marking rates than comparable brands. Sisma LOGO marking laser works by utilizing Fiber Ytterbium laser beam which emit light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser). Sisma LOGO works very well for marking barcode on CNC product, name plates or manufacturing batch plate, and various other seamless application on any type of metal and composite surface. Sisma Laser Marking Smarky OEM Series Features: Using the market's highest class IV laser source technology Includes intuitive software compatible with small to medium scale application Enclosed system and sealed laser source for minimal maintenance Suitable for production line which requires high quality marking on low volume application. Lasers can be supplied with some accessories like the rotating spindle, Z manual axis, plates feeder and guide-plate dragger

Sisma OEM marking unit is the answer to your need of laser marking with slight depth engraving on all types of metallic material surface as in metalworking mould & dies, jewellery, solid material and hard composite plastic. You can easily which is easily configure the appropriate paraeter through Sisma's user friendly computer software. Sisma OEM's software are intuitive and fully compatible with all types of files like SVG, DXF, BMP, JPG even PLT formatted.

From a simple batch plate signature on your products to creating and marking different types of data, bar codes and matrix data on your product's metal case, Sisma OEM can do it all. You can say goobye to the old chemical etching method, manual engraving, micro milling, rubber ball transfer stamp and transfer screen paint mesh which are messy and consistently requires skilled workers.

The Sisma OEM marking machine itself is the only reasonable and economical investment in terms of seamless marking details, accuracy and user friendly software. Thanks to its class IV laser source level, you can have a concentrated heat source with narrower and faster marking rates than comparable brands. Sisma LOGO marking laser works by utilizing Fiber Ytterbium laser beam which emit light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser). Sisma LOGO works very well for marking barcode on CNC product, name plates or manufacturing batch plate, and various other seamless application on any type of metal and composite surface.

Sisma Laser Marking Smarky OEM Series Features:

- Using the market's highest class IV laser source technology

- Includes intuitive software compatible with small to medium scale application

- Enclosed system and sealed laser source for minimal maintenance

- Suitable for production line which requires high quality marking on low volume application.

- Lasers can be supplied with some accessories like the rotating spindle, Z manual axis, plates feeder and guide-plate dragger

Overview

Durability

User Friendly

TECHNICAL SPECIFICATION

Sisma Smarky OEM Series Ordering Guide:

| OEM 10 W | OEM 12 W | OEM 20 W | |

| Wavelength | 1064 nm | 1070 nm | 1070 nm |

| Laser technology | YV04 | Yb | Yb |

| Repetition rate range | 2 - 100 KHz | 2 - 1,000 KHz | 2 - 200 KHz |

| Pulse width | 35 ns | 9 - 250 ns | 200 ns |

| Max. pulse energy | 0.7 mJ | 0.6 mJ | 0.8 mJ |

| M2 | ≤1.5 | ≤1.6 | ≤1.5 |

| Beam spot diameter f160 | 20 µm | 16 µm | 20 µm |

| Supplied accessories | Embedded PC | - | - |

Sisma Smarky OEM Series Alternatives:

| OEM Plus 10 W | OEM Plus 12 W | OEM Plus 20 W | OEM Plus 40 W | OEM Plus 50 W | |

| Wavelength [nm] | 1064 nm | 1070 nm | 1070 nm | 1070 nm | 1070 nm |

| Laser technology | YV04 | Yb | Yb | Yb | Yb |

| Repetition rate range [KHz] | 2 - 100 KHz | 2 - 1,000 KHz | 2 - 200 KHz | 2 - 1,000 KHz | 50 - 200 KHz |

| Pulse width [ns] | 35 ns | 9 - 250 ns | 200 ns | 9 - 250 ns | 200 ns |

| Max. pulse energy [mJ] | 0.7 mJ | 0.6 mJ | 0.8 mJ | 1.25 mJ | 1 mJ |

| M2 | ≤1.8 | ≤1.6 | ≤1.5 | 3 | 2 |

| Beam spot diameter f160 | 20 µm | 16 µm | 20 µm | 30 µm | 25 µm |

| Supplied accessories |

Z motorized axis, fumes aspirator, 3D, feeding plate, spindle |

Z motorized axis, fumes aspirator, 3D, feeding plate, spindle |

Z motorized axis, fumes aspirator, 3D, feeding plate, spindle |

Z motorized axis, fumes aspirator, 3D, feeding plate, spindle |

Z motorized axis, fumes aspirator, 3D, feeding plate, spindle |

Request a Quote

Request A Quote

Please complete the below form to receive further information.