- Home

- Products

- Cutting Tools

- End Mills / Slot Drill

- WIDIA GP Solid Carbide End Mills

If you want to find out more about

WIDIA GP Solid Carbide End Mills

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Solid End Mills/High-Performance Solid Carbide End Mills/H/P Solid Carbide • VariMill™ Widia's VariMill GP offers plunging, slotting, and profiling for a wide range of materials and applications. Widia's VariMill GP are designed for either rouhing or finishing work which features high metal removal rates and good surface conditions at a value price. Widia's VariMill GP offers variety range of diameters, lengths, and corner styles (such as chamfered, sharp edge, and ball nose). Though primarily designed for roughing and finishing applications in the aerospace industry, VariMill II ER tools can be used as a solution for any titanium or stainless steel machining and are capable of slotting, ramping, and plunging. Widia's VariMill GP Eccentric relief are availabe on both 2 flute for high flexibility in unstable conditions and 4 flute for higher metal removal rates and prolonged tool life. Widia's VariMill GP is developed to answer your needs of versatility, compact inventory and economical. Like the VariMill II, VariMill II ER end mills have the eccentric relief (ER) available with this new tool’s cutting edges provides greater edge strength and enables high feeds and metal removal rates. The VariMill II ER end mill has a different taper core than VariMill I and II for increased stability and robust performance, and also differs from its predecessors in that it is designed for center cutting. VariMill II ER also is the first off-the-shelf tool to offer SAFE-LOCK™ by Haimer, which provides excellent stability, eliminates pull-out risk, and makes the tool more stable and concentric, overall. SAFE-LOCK is available on tools >1/2" (12mm) in diameter. WIDIA GP Solid Carbide End Mills Features: VariMill II ER tools can be used as a solution for any titanium or stainless steel machining and are capable of slotting, ramping, and plunging. More than 100 VariMill II ER standard line items will be available globally in diameters from 3/8–1" (10–25mm). Engineered with five unequally spaced flutes. Unequal flute spacing allow for center cutting within ramping angle of 3°. Optimized for difficult-to-machine work piece materials . Semi-finishing to finishing applications for high-speed machining capability. PDF catalog on metric can be downloaded here and on inches here

Solid End Mills/High-Performance Solid Carbide End Mills/H/P Solid Carbide • VariMill™

Widia's VariMill GP offers plunging, slotting, and profiling for a wide range of materials and applications. Widia's VariMill GP are designed for either rouhing or finishing work which features high metal removal rates and good surface conditions at a value price. Widia's VariMill GP offers variety range of diameters, lengths, and corner styles (such as chamfered, sharp edge, and ball nose). Though primarily designed for roughing and finishing applications in the aerospace industry, VariMill II ER tools can be used as a solution for any titanium or stainless steel machining and are capable of slotting, ramping, and plunging.

WIDIA GP Solid Carbide End Mills Features:

Widia's VariMill GP Eccentric relief are availabe on both 2 flute for high flexibility in unstable conditions and 4 flute for higher metal removal rates and prolonged tool life. Widia's VariMill GP is developed to answer your needs of versatility, compact inventory and economical. Like the VariMill II, VariMill II ER end mills have the eccentric relief (ER) available with this new tool’s cutting edges provides greater edge strength and enables high feeds and metal removal rates.

The VariMill II ER end mill has a different taper core than VariMill I and II for increased stability and robust performance, and also differs from its predecessors in that it is designed for center cutting. VariMill II ER also is the first off-the-shelf tool to offer SAFE-LOCK™ by Haimer, which provides excellent stability, eliminates pull-out risk, and makes the tool more stable and concentric, overall. SAFE-LOCK is available on tools >1/2" (12mm) in diameter.

WIDIA GP Solid Carbide End Mills Features:

- VariMill II ER tools can be used as a solution for any titanium or stainless steel machining and are capable of slotting, ramping, and plunging.

- More than 100 VariMill II ER standard line items will be available globally in diameters from 3/8–1" (10–25mm).

- Engineered with five unequally spaced flutes.

- Unequal flute spacing allow for center cutting within ramping angle of 3°.

- Optimized for difficult-to-machine work piece materials .

- Semi-finishing to finishing applications for high-speed machining capability.

- PDF catalog on metric can be downloaded here and on inches here

Overview

Built to last

Since 1929, WIDIA holds the world’s first patent for coating indexable inserts, taps and mills with Tungsten carbide application on cutting-tools. Widia cutting tools are recorded adheres to every DIN, ISO standard and several JIS standard for easier conversion and replacement.

Customer values

With thousands of milling, turning, holemaking, and tooling systems products available you´ll find everything you need from one single source. Widia master the coating technology from TICN coating, CBN (Superhard cubic boron nittride /cBN) for Cast Iron / Sintered Metals, and PCD (diamond) tip for highly abrasive material.

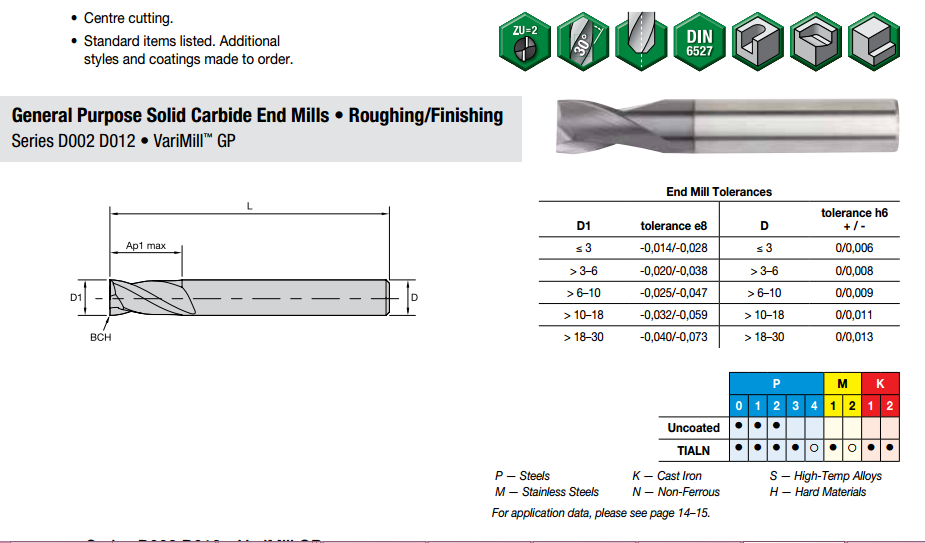

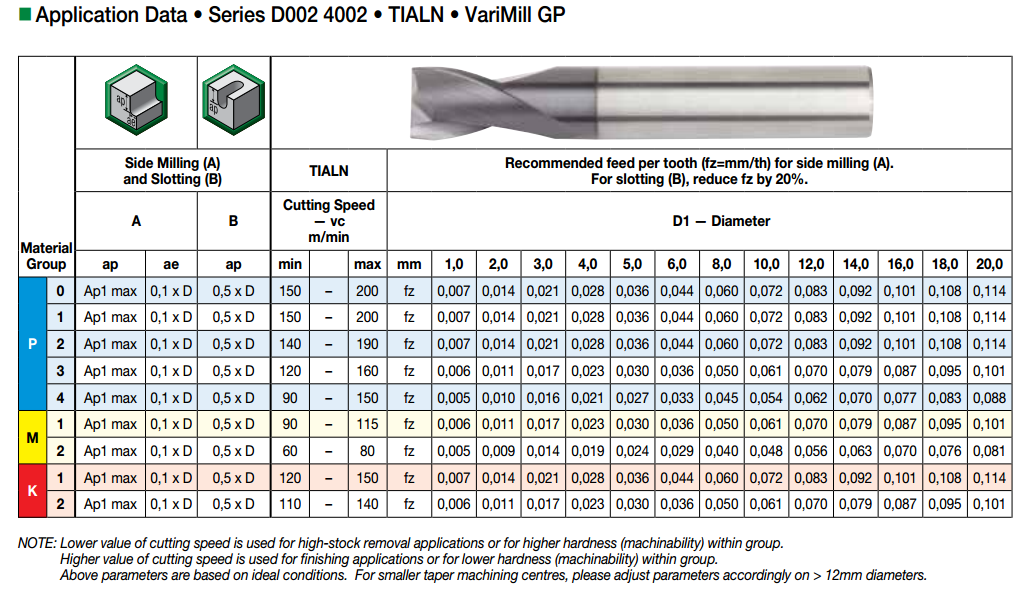

TECHNICAL SPECIFICATION

WIDIA VariMill™ GP End Mills

Click here for detailed technical specification.

Request a Quote

Request A Quote

Please complete the below form to receive further information.