- Home

- Products

- Circular Saw Machines

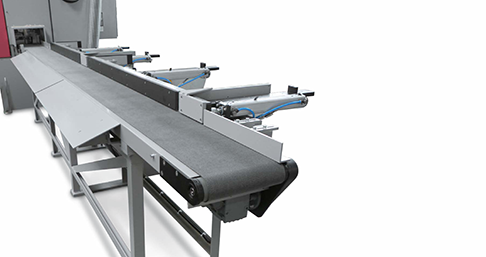

- Behringer Multi-Fluid Circular Saw Machine HC S Series

If you want to find out more about

Behringer Multi-Fluid Circular Saw Machine HC S Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Limits are newly defined. Shorter cycle times, higher output – the Multi-Fluid concept of the HCS MF-series opens new horizons of efficiency thanks to its pinpoint cooling during the cutting process. The Multi-Fluid system is excellent for high-alloy stainless steels and tool steels, nickel-based alloys like Inconel and Hastelloy as well as titanium alloys. Depending on the requirements, the following cooling/lubrication components can be combined most effectively: Coolant nozzles for wet processing Micro-spraying device for minimum quantity lubrication Cooling vortex tube for dry processing The results: effective cooling allows for high feed rates and shorter cutting cycles, while also increasing tool life considerably. Combined with the large saw blade diameter range (up to 520 mm), the HCS-MF automatic circular cold saws are unbeatable in their flexibility and profitability. Constant weight feature – 100 % good parts This feature is particularly useful for the forging industry. An automatic query of the material diameter ensures a constant weight of the pieces cut. Before the cut, the workpiece is measured and any variations in diameter are compensated by adjusting the cutting length accordingly. Ask our engineers for complete solutions for your requirements. It pays! Multi-Fluid cooling system Depending on the application or the material characteristics, the following three cooling/lubrication components can be combined most effectively: Coolant jet nozzles for wet processing Micro-spraying device for minimum quantity lubrication Cooling vortex tube for dry processing Blade vibration absorber (BVA)The perfect interaction between the largely-dimensioned carbide metal guides and an effective brush system, which proactively removes chips, ensures not only a maximum service life but also an optimized cutting surface and a precise and swift cutting operation. It can be easily adjusted to different blade thicknesses.

Limits are newly defined. Shorter cycle times, higher output – the Multi-Fluid concept of the HCS MF-series opens new horizons of efficiency thanks to its pinpoint cooling during the cutting process. The Multi-Fluid system is excellent for high-alloy stainless steels and tool steels, nickel-based alloys like Inconel and Hastelloy as well as titanium alloys.

Depending on the requirements, the following cooling/lubrication components can be combined most effectively:

- Coolant nozzles for wet processing

- Micro-spraying device for minimum quantity lubrication

- Cooling vortex tube for dry processing

The results: effective cooling allows for high feed rates and shorter cutting cycles, while also increasing tool life considerably. Combined with the large saw blade diameter range (up to 520 mm), the HCS-MF automatic circular cold saws are unbeatable in their flexibility and profitability.

Constant weight feature – 100 % good parts

This feature is particularly useful for the forging industry. An automatic query of the material diameter ensures a constant weight of the pieces cut. Before the cut, the workpiece is measured and any variations in diameter are compensated by adjusting the cutting length accordingly. Ask our engineers for complete solutions for your requirements. It pays!

Multi-Fluid cooling system

Depending on the application or the material characteristics, the following three cooling/lubrication components can be combined most effectively:

- Coolant jet nozzles for wet processing

- Micro-spraying device for minimum quantity lubrication

- Cooling vortex tube for dry processing

Blade vibration absorber (BVA)The perfect interaction between the largely-dimensioned carbide metal guides and an effective brush system, which proactively removes chips, ensures not only a maximum service life but also an optimized cutting surface and a precise and swift cutting operation. It can be easily adjusted to different blade thicknesses.

Overview

Customer value

Behringer machinery are rigid, torsionally-resistant and low-vibration sawing frames in a stable cast design and backlash-free pre-tensioned quadruple guides for precision sawing results. Behringer band saw is covered with two (2) years of limited warranty.

Built to last

BEHRINGER Vertical circular saw VMS is manufactured by BEHRINGER GmbH of which was founded in Germany 1919. after taking over circular sawing specialist EISELE in the year 2000, BEHRINGER GmbH has been one of the few complete suppliers in the sawing technology market

TECHNICAL SPECIFICATION

Behringer Eisele HCS Multi-Fluid

| Model | HC S 100 MF | HC S 130 MF | |

| Saw blade diameter | [mm] | 285 / 315 / 360 | 315 / 360 / 420 |

| BVA - Blade Vibration Absorber | optional | optional | |

| Cutting range 90° round | [mm] | 20 - 105 | 20 - 130 |

| Cutting range 90° square | [mm] | 20 x 20 - 90 x 90 | 20 x 20 - 110 x 110 |

| Standard blade speed | [1/min] | 20 - 250 | 20 - 250 |

| Drive power – frequency-controlled | [kW] | 22.5 | 22.5 |

| Min. rest piece length | [mm] | 70 | 70 |

| Feed length single stroke | [mm] | 1000 | 1000 |

| Max. material feed rate | [mm/sec] | 1000 | 1000 |

| Saw feed rate | [mm/sec] | 0,5 - 40 | 0,5 - 40 |

| Dimensions without magazine L x W x H |

[mm] | 2660 x 2650 x 2450 | 2660 x 2650 x 2450 |

| Weight without magazine (approx.) | [kg] | 5500 | 5500 |

| Model | HC S 160 MF | HC S 180 MF | |

| Saw blade diameter | [mm] | 360 / 420 / 460 / 480 | 460 / 520 |

| BVA - Blade Vibration Absorber | standard | standard | |

| Cutting range 90° round | [mm] | 20 - 160 | 40 - 180 |

| Cutting range 90° square | [mm] | 20 x 20 - 140 x 140 | 40 x 40 - 150 x 150 |

| Standard blade speed | [1/min] | 20 - 250 | 20 - 200 |

| Drive power – frequency-controlled | [kW] | 22.5 | 28 |

| Min. rest piece length | [mm] | 70 | 80 |

| Feed length single stroke | [mm] | 1000 | 1000 |

| Max. material feed rate | [mm/sec] | 1000 | 800 |

| Saw feed rate | [mm/sec] | 0,5 - 40 | 0,5 - 40 |

| Dimensions without magazine L x W x H |

[mm] | 2660 x 2650 x 2450 | 2660 x 2650 x 2450 |

| Weight without magazine (approx.) | [kg] | 5500 | 6000 |

Request a Quote

Request A Quote

Please complete the below form to receive further information.