- Home

- Products

- Bandsaw Machines

- Straight-Cutting

- Behringer High-Performance Automatic Bandsaw HBM440A

If you want to find out more about

Behringer High-Performance Automatic Bandsaw HBM440A

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Behringer High-Performance Automatic Bandsaw HBM440A Unbeatable speed – even with the toughest jobs The Behringer HBM series addresses the most stringent demands in terms of cutting output, automation and process reliability in the steel trade and production, BEHRINGER HBM series high-performance automatic bandsaw machines offer an impressive package of benefits. From non-ferrous metals and aluminum through steel to Inconel or titanium. The HBM series bandsaw machines are characterized by the combination of highest cutting performance, precision, and reliability. Highest performance through innovative Speed-Cutting technology The innovative Speed-Cutting technology of the HBM series allows process-reliable cutting performance that was previously unthinkable. It shows its full potential especially when cutting tool steels to stainless steels or high-alloy materials such as Inconel or Titanium in industry and the steel trade. Thanks to the combination of a powerful machine base, modern servo technology, innovative cooling system and process-reliable chip disposal, the HBM gets the maximum out of the tool used - regardless of whether it is a carbide or bi-metal blade. Features of the HBM440A Speed-Cutting Technology The high-performance sewing unit can be fitted with the Behringer Speed-Cutting technology as an option. The combination of Speed-Cutting saw blade guides, high-performance cooling system, dynamically controlled saw feed and specially optimized Auto-Feed-Control allows you to get the maximum performance and tool life. Cast Iron Bandsaw Guide Manufactured by Behringer, the band guide provides vibration damping effect. It directly reduces vibration at the edge where the material is cut. As a result, the bandsaw blade tool life is increased. Duplex Chip Brush With the Behringer quick-change device for tool-free brush changes, the teeth of the bandsaw blades are protected by a special engagement angle. Optimum Chip Disposal Highest cutting performance requires exacting standards of chip disposal. Optimal chip disposal is achieved thanks to the funnel-shaped machine base and the paddle-style chip conveyor with an integrated coolant tank. The ejection height of 800 mm or 1,200 mm option allows the use of large chip buckets. Servo Downfeed System The saw feed is carried out by means of a ball screw and servo motor with cutting pressure control. This results in significantly shorter idle times and more precise saw feeds. Your advantages: higher cutting performance and longer bandsaw blade tool life! HBM Band Guide with High-Performance Cooling Economical Use of Carbide Saw Blades Achieve the highest cutting performance when sawing with bimetal and carbide saw blades. This is made possible due to the robust design, the use of the latest servo technology and well-dimensioned chip disposal. Other Features: Prepared for automation A powerful machine concept puts high demands on material handling. The high-performance bandsaws of the HBM series are often configured as automated sawing systems. Therefore, the machines are already prepared in basic configuration for the connection of extensive material handling equipment. Sensitive BEHRINGER cutting pressure control Increases the cutting performance when sawing tubes and profiles, as it automatically adapts the saw feed of the machine to the changing material cross-sections. Due to the arrangement directly at the back of the blade, the system regulates quickly and precisely. Precision portal-design guide system The combination of stable, low vibration saw frame and the linear guide system in portal design ensure the best cutting results and maximum service life. Automatic guide arm Optimum sawing result without any adjustments - even with frequently changing material sizes. LFC is the exclusive distributor for Behringer sawing machines in Singapore and Malaysia. The HBM440A can be configured perfectly to your requirements with numerous options. This is how you get the most out of your production. Our team will be pleased to advise you. Contact us for a discussion! LFC PTE LTD 8 Ubi Rd 2, #03-01, Zervex Singapore 408538 EMAIL sales@lfc.com.sg PHONE (65) 6749 9697

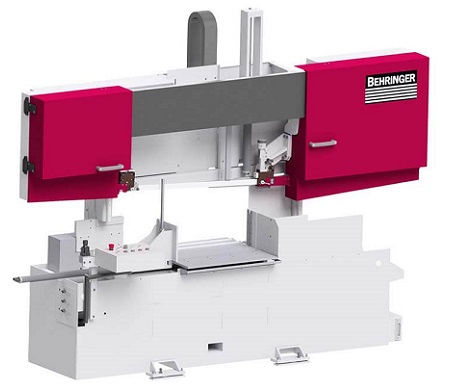

Behringer High-Performance Automatic Bandsaw HBM440A

Unbeatable speed – even with the toughest jobs

The Behringer HBM series addresses the most stringent demands in terms of cutting output, automation and process reliability in the steel trade and production, BEHRINGER HBM series high-performance automatic bandsaw machines offer an impressive package of benefits. From non-ferrous metals and aluminum through steel to Inconel or titanium. The HBM series bandsaw machines are characterized by the combination of highest cutting performance, precision, and reliability.

Highest performance through innovative Speed-Cutting technology

The innovative Speed-Cutting technology of the HBM series allows process-reliable cutting performance that was previously unthinkable. It shows its full potential especially when cutting tool steels to stainless steels or high-alloy materials such as Inconel or Titanium in industry and the steel trade. Thanks to the combination of a powerful machine base, modern servo technology, innovative cooling system and process-reliable chip disposal, the HBM gets the maximum out of the tool used - regardless of whether it is a carbide or bi-metal blade.

Features of the HBM440A

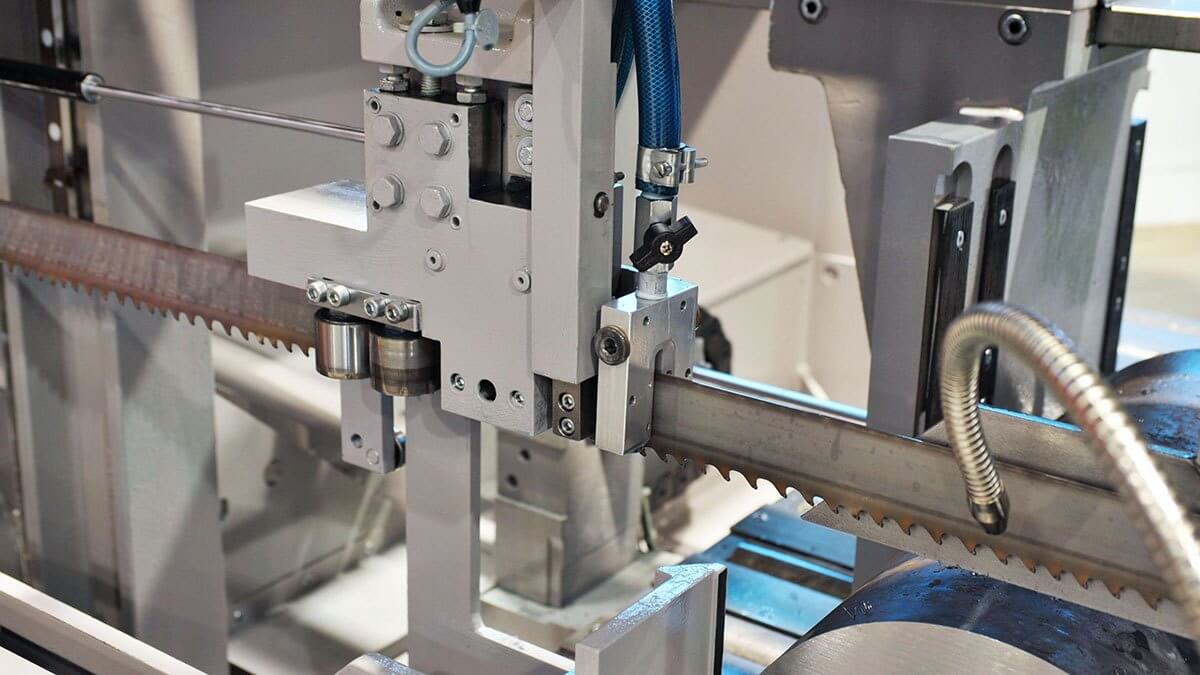

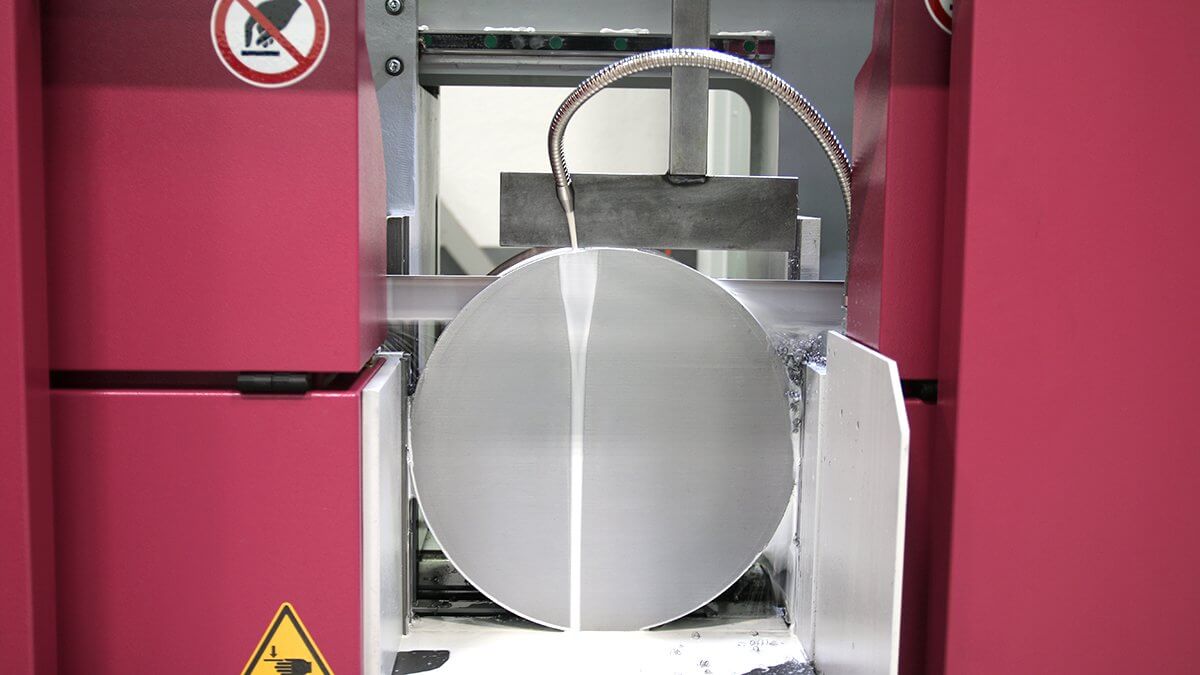

Speed-Cutting Technology

The high-performance sewing unit can be fitted with the Behringer Speed-Cutting technology as an option. The combination of Speed-Cutting saw blade guides, high-performance cooling system, dynamically controlled saw feed and specially optimized Auto-Feed-Control allows you to get the maximum performance and tool life.

Cast Iron Bandsaw Guide

Manufactured by Behringer, the band guide provides vibration damping effect. It directly reduces vibration at the edge where the material is cut. As a result, the bandsaw blade tool life is increased.

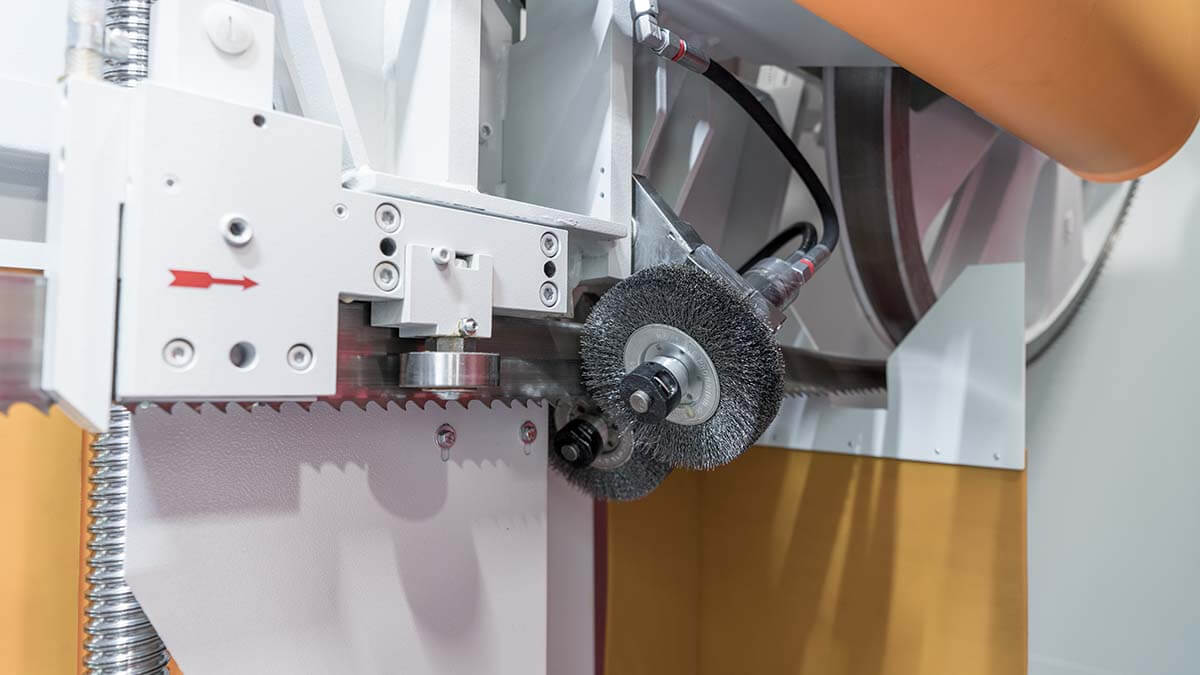

Duplex Chip Brush

With the Behringer quick-change device for tool-free brush changes, the teeth of the bandsaw blades are protected by a special engagement angle.

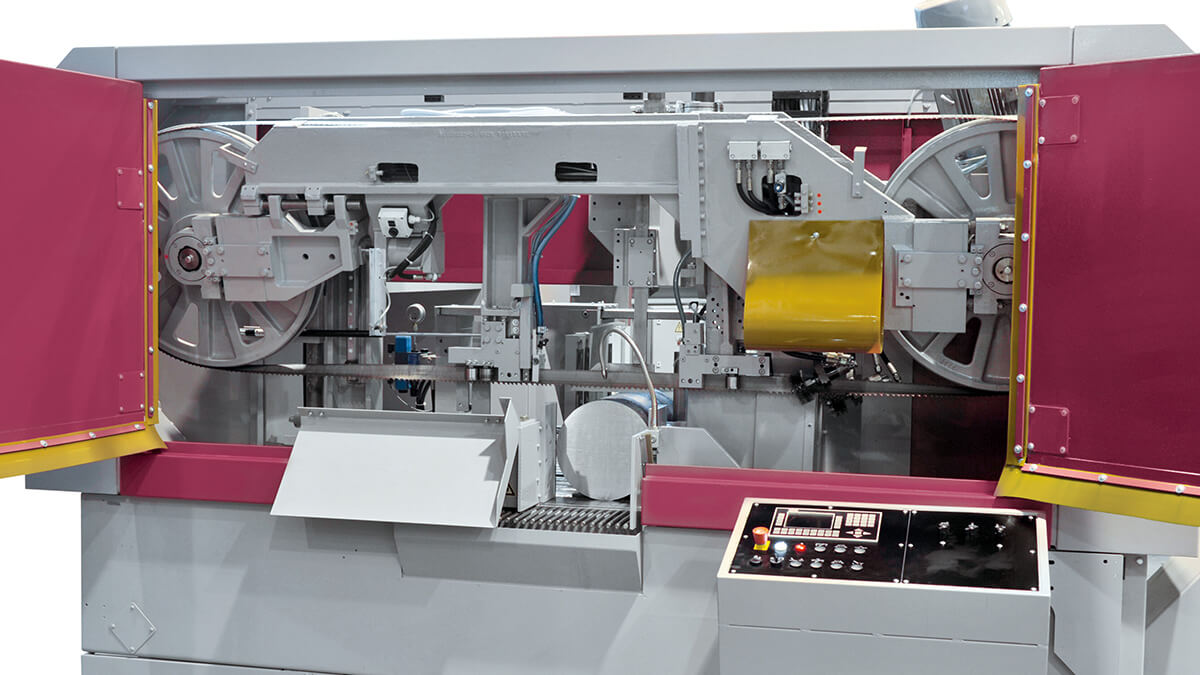

Optimum Chip Disposal

Highest cutting performance requires exacting standards of chip disposal. Optimal chip disposal is achieved thanks to the funnel-shaped machine base and the paddle-style chip conveyor with an integrated coolant tank. The ejection height of 800 mm or 1,200 mm option allows the use of large chip buckets.

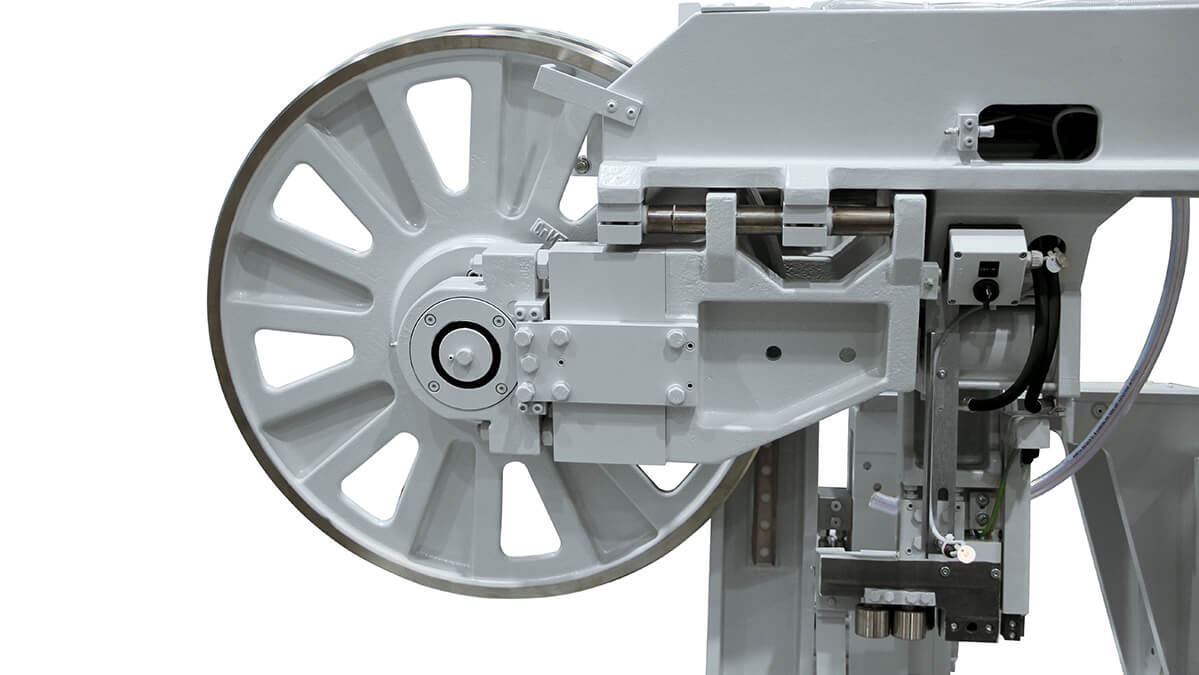

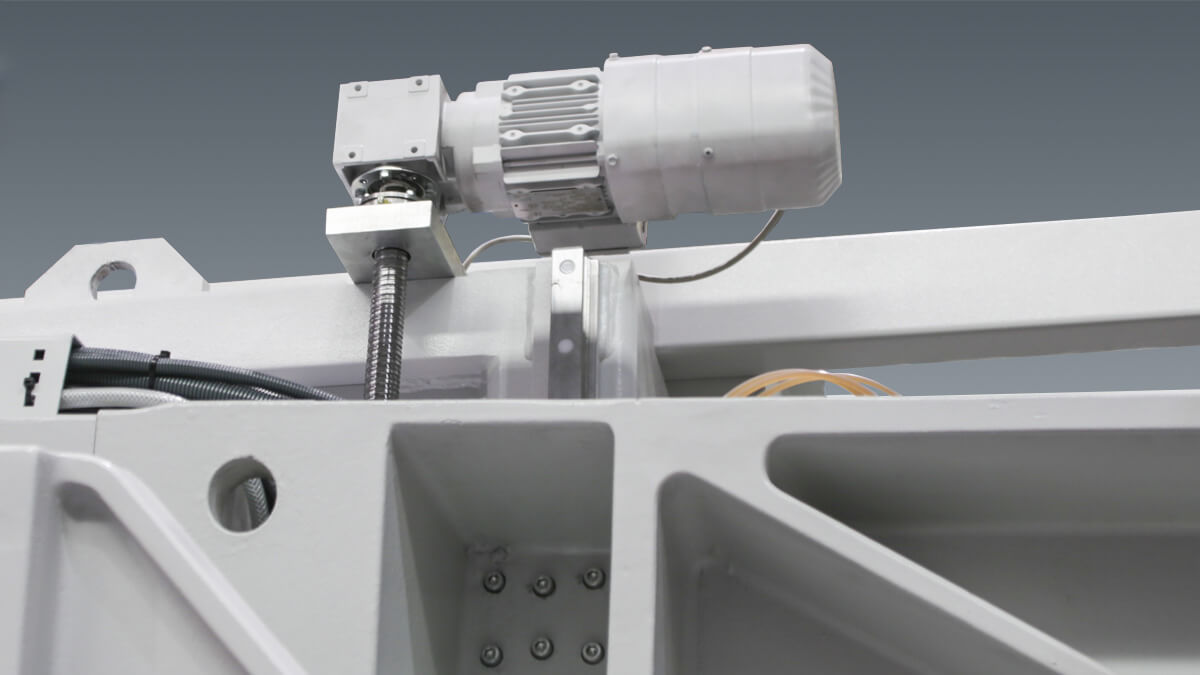

Servo Downfeed System

The saw feed is carried out by means of a ball screw and servo motor with cutting pressure control. This results in significantly shorter idle times and more precise saw feeds. Your advantages: higher cutting performance and longer bandsaw blade tool life!

HBM Band Guide with High-Performance Cooling

Economical Use of Carbide Saw Blades

Achieve the highest cutting performance when sawing with bimetal and carbide saw blades. This is made possible due to the robust design, the use of the latest servo technology and well-dimensioned chip disposal.

Other Features:

Prepared for automation

A powerful machine concept puts high demands on material handling. The high-performance bandsaws of the HBM series are often configured as automated sawing systems. Therefore, the machines are already prepared in basic configuration for the connection of extensive material handling equipment.

Sensitive BEHRINGER cutting pressure control

Increases the cutting performance when sawing tubes and profiles, as it automatically adapts the saw feed of the machine to the changing material cross-sections. Due to the arrangement directly at the back of the blade, the system regulates quickly and precisely.

Precision portal-design guide system

The combination of stable, low vibration saw frame and the linear guide system in portal design ensure the best cutting results and maximum service life.

Automatic guide arm

Optimum sawing result without any adjustments - even with frequently changing material sizes.

LFC is the exclusive distributor for Behringer sawing machines in Singapore and Malaysia. The HBM440A can be configured perfectly to your requirements with numerous options. This is how you get the most out of your production. Our team will be pleased to advise you. Contact us for a discussion!

Overview

Customer value

Behringer are rigid, torsionally-resistant and low-vibration sawing frames in a stable cast design and backlash-free pre-tensioned quadruple guides for precision sawing results and low maintenance with two(2) years of limited warranty

Built to last

BEHRINGER GmbH was founded in Germany 1919. after taking over circular sawing specialist EISELE in the year 2000, BEHRINGER GmbH has been the leading suppliers in the sawing technology market

TECHNICAL SPECIFICATION

| Cutting Range | |

| Cutting range 90° round | 440 mm |

| Cutting range 90° flat | 440 x 440 mm |

| Smallest dimension to be sawn round | 15 mm |

| Smallest dimension to be sawn flat | 12 x 12 mm |

| Performance Characteristics | |

| Feeding length single stroke | 600 mm |

| Drive Power | 5.5 kW |

| Blade Speed | 13 - 130 m/min |

| Saw Blade Dimension | 6,700 x 54 x 1.3 mm |

| Rest piece length in automatic operation | 35 mm |

| Total power |

12 kW |

| Saw feed | servo-feed via ball screw |

| Material feed |

ball screw |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

| Dimension & Weight | |

| Length | 2,650 mm |

| Width | 4,385 mm |

| Height | 2,700 mm |

| Weight | 4,600 kg |

| Material support height | 800 mm |

Request a Quote

Request A Quote

Please complete the below form to receive further information.