If you want to find out more about

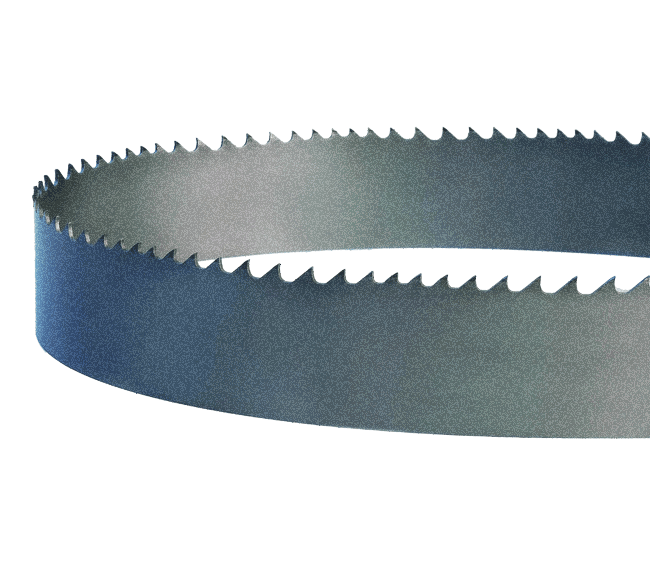

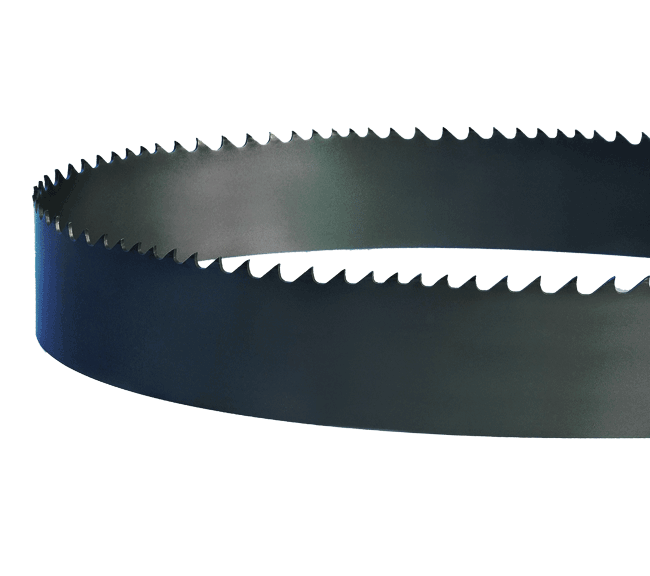

DoALL Tungsten Carbide Saw Blade T7P Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

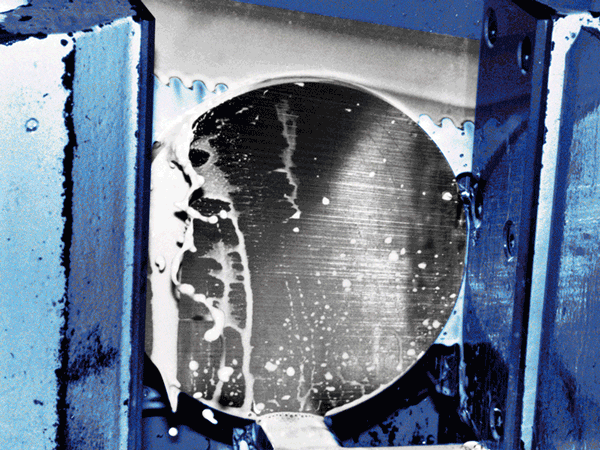

DoALL Tungsten Carbide Saw T7P is designed with tungsten carbide as the main material, as it can resist high temperatures and is extremely reliable in cutting superalloys on various bandsaws and reciprocating saws. The DoALL Tungsten Carbide Saw Blade T7P overall is two times stiffer than regular steel, with a Young's modulus of approximately 530–700 GPa and is much denser than any regular steel even titanium. DoALL Tungsten Grit Segmented Saw Blade T7P is very abrasion resistant and withstand higher temperatures than standard high speed steel saw. DoALL Tungsten Grit Segmented Saw Blade T7P maintain a sharp cutting edge better and generally produce a better finish on parts. DoALL Tungsten Carbide Saw Blade T7P allows a faster rate of cutting and reliable especially when you are working on busy queue. Depends on your machinery set up, DoALL Tungsten Carbide Saw Blade T7P performs consistently balanced between power delivery versus cutting ratio for a cost effective job on cutting High-Nickel Alloys. DoALL Tungsten Carbide Saw Blade T7P is particularly suitable when you need the reliability and versatility in working with oil and gas tube, ammunition, high compression chemical tube and varieties of titanium blanks in CNC fabrication. Features Tungsten Carbide tooth Positive rake tooth Benefits Most heat resistant Aggressive sawing with a smooth finish Enhanced penetration for the toughest metals Applications Large diameter super alloys, high nickel alloys, titanium etc.

DoALL Tungsten Carbide Saw T7P is designed with tungsten carbide as the main material, as it can resist high temperatures and is extremely reliable in cutting superalloys on various bandsaws and reciprocating saws. The DoALL Tungsten Carbide Saw Blade T7P overall is two times stiffer than regular steel, with a Young's modulus of approximately 530–700 GPa and is much denser than any regular steel even titanium. DoALL Tungsten Grit Segmented Saw Blade T7P is very abrasion resistant and withstand higher temperatures than standard high speed steel saw. DoALL Tungsten Grit Segmented Saw Blade T7P maintain a sharp cutting edge better and generally produce a better finish on parts. DoALL Tungsten Carbide Saw Blade T7P allows a faster rate of cutting and reliable especially when you are working on busy queue.

Depends on your machinery set up, DoALL Tungsten Carbide Saw Blade T7P performs consistently balanced between power delivery versus cutting ratio for a cost effective job on cutting High-Nickel Alloys. DoALL Tungsten Carbide Saw Blade T7P is particularly suitable when you need the reliability and versatility in working with oil and gas tube, ammunition, high compression chemical tube and varieties of titanium blanks in CNC fabrication.

Features

- Tungsten Carbide tooth

- Positive rake tooth

Benefits

- Most heat resistant

- Aggressive sawing with a smooth finish

- Enhanced penetration for the toughest metals

Applications

- Large diameter super alloys, high nickel alloys, titanium etc.

Overview

Customer values

Built to perfoms

TECHNICAL SPECIFICATION

DoALL Tungsten Carbide Saw Blade T7P Ordering Guide:

| Metric | T7P | |||||

| Width | Gauge | 0,7-1 | 1-1,3 | 1,3-2 | 2-3 | 3-4 |

| 27 | 0,9 | 332-234 | ||||

| 34 | 1,1 | 332-323 | 332-334 | |||

| 41 | 1,4 | 332-432 | 332-423 | 332-434 | ||

| 54 | 1,6 | 332-571 | 332-511 | 332-532 | 332-523 | |

| 67 | 1,6 | 332-671 | 332-611 | 332-632 | ||

| 80 | 1,6 | 332-771 | 332-711 | |||

You can also download DoALL Saw Blade catalogs here

Request a Quote

Request A Quote

Please complete the below form to receive further information.