If you want to find out more about

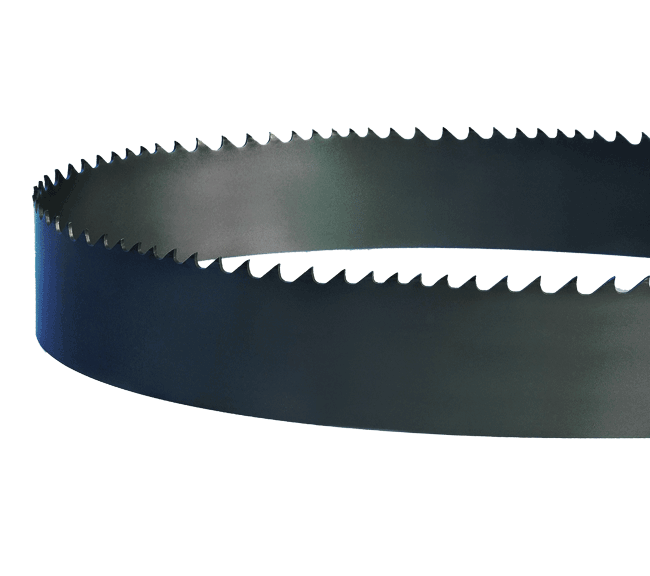

DoALL Bi-Metal Bandsaw Blade Penetrator Prime

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Premium blade for moderate to difficult alloys on a power saw for high-production cutting with extended blade life. DoALL Penetrator Prime Saw is designed with powder metal tooth with a hardness of 70 HRc and high positive rake angle, curvilinear tooth foam. DoALL Penetrator Prime Saw is the most wear-resistant Bi-metal tooth. Premium blade for moderate to difficult alloys on the power saw for high production cutting with extended blade life. DoALL Penetrator prime is fast cutting and wear-resistant blade designed for production sawing. Use these blades to saw moderate to difficult alloys in power saws for high production rates with extended blade life such as Aluminium, copper, brass, free machining steels, mild steels, low carbon, alloy steels, high carbon, tool steels, die steels, stainless steels, titanium, nickel-based alloys, high nickel alloys, and superalloys. Premium blade for difficult alloys Medium to difficult alloys High production sawing Single, bundle, or nest Features : Powder metal tooth with a hardness of 70 HRc Highly positive rake angle curvilinear tooth Benefits : Fast-cutting, wear-resistant blade Designed for production sawing Applications : Moderate to difficult alloys on power saws for high-production cutting with extended blade life

Premium blade for moderate to difficult alloys on a power saw for high-production cutting with extended blade life. DoALL Penetrator Prime Saw is designed with powder metal tooth with a hardness of 70 HRc and high positive rake angle, curvilinear tooth foam. DoALL Penetrator Prime Saw is the most wear-resistant Bi-metal tooth. Premium blade for moderate to difficult alloys on the power saw for high production cutting with extended blade life.

DoALL Penetrator prime is fast cutting and wear-resistant blade designed for production sawing. Use these blades to saw moderate to difficult alloys in power saws for high production rates with extended blade life such as Aluminium, copper, brass, free machining steels, mild steels, low carbon, alloy steels, high carbon, tool steels, die steels, stainless steels, titanium, nickel-based alloys, high nickel alloys, and superalloys.

Premium blade for difficult alloys

- Medium to difficult alloys

- High production sawing

- Single, bundle, or nest

Features :

- Powder metal tooth with a hardness of 70 HRc

- Highly positive rake angle curvilinear tooth

Benefits :

- Fast-cutting, wear-resistant blade

- Designed for production sawing

Applications :

- Moderate to difficult alloys on power saws for high-production cutting with extended blade life

Overview

Customer values

Built to perfoms

TECHNICAL SPECIFICATION

DoALL Bi-Metal Bandsaw Blade Penetrator Prime Ordering Guide:

|

Metric |

Penetrator Prime |

||||||

|

Width |

Gauge |

1-1.5 |

1.5-2 |

2-3 |

3-4 |

4-6 |

5-8 |

|

27 |

0.9 |

|

|

|

307-660 |

307-665 |

307-670 |

|

34 |

1.1 |

|

|

307-689 |

307-739 |

307-759 |

307-760 |

|

41 |

1.3 |

|

307-877 |

307-879 |

307-887 |

307-893 |

|

|

54 |

1.6 |

|

307-901 |

307-902 |

307-903 |

307-546 |

|

|

67 |

1.6 |

307-911 |

307-913 |

307-912 |

|

|

|

Request a Quote

Request A Quote

Please complete the below form to receive further information.