- Home

- Products

- Leak Testing & Flow Measurement

- Flow Tester

- Flow Tester CETATEST 915-G

If you want to find out more about

Flow Tester CETATEST 915-G

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

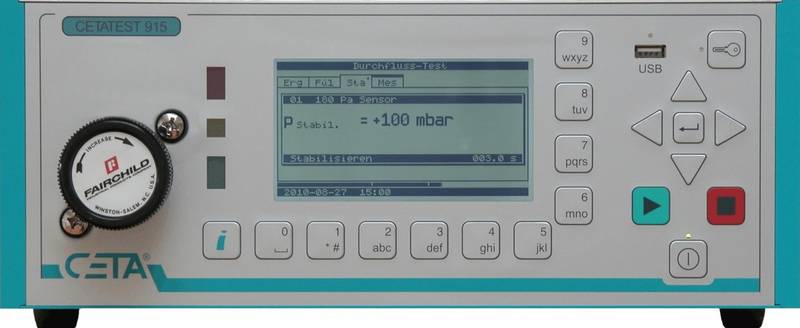

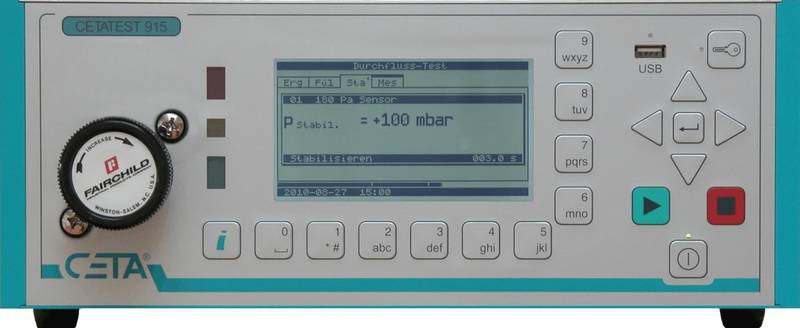

The CETATEST 915-G is a fully automatic flow test device for the detection of leaking parts. The principle of CETATEST 915-G is quite similar with Flow Tester CETATEST 915 and actually differ only in ranges. They both are using the pressure drop of the laminar flow element (LFE) which then measured by a differential pressure sensor and converted into a flow value. The differential means that the Piezo-resistive gage pressure sensor also measure the actual value by comparing the current measurement of test with allowed parameter setting automatically. CETATEST 915-G's differential pressure sensor and relative pressure sensor capable of testing pressure ranges from 150 mbar to 600 mbar (other pressures on request). The test is automatically started after adaption of the test part. The CETATEST 915-G method of operation has been specially developed for the gas industry, for reworking in the automobile industry, gas circuit system installation and for reworking in the automobile industry and various other application. Your investment on Flow Tester CETATEST 915 will lead your way to unlocks higher level of precision in detecting irregularity of flow on both very small to medium ratios of test part volumes on mass production system. The test itself is automatically started after adaption of the test part. With the CETA flow testers, the volume flow through the test part can be measured conveniently. By the use of appropriate laminar flow elements a wide range of flows can also be covered. Flow Tester CETATEST 915 Features: Laminar flow element with differential pressure transducer Abilities for direct or indirect test method Much cheaper and safer alternative than other NDT method. Test pressure sensor is using Piezo-resistive gage pressure sensor Flow measurement range is 0 to 2 ml/min resp. 0 to 120 ml/h (depending on the type of the laminar flow element) Unit of measurement are ml/min, ml/h, l/min, l/h Pressure controller is using both mechanical and electronical method Ideal test pressure range are 150 mbar • 600 mbar Compact form factor of 345 mm x 145 mm x 435 mm (W x H x D) Suitable application Tests of valves, exhaust gas systems, pipes, membranes, automation filling, within the automated cycle of food-beverages packaging industry, pharmaceuticals, medical equipment and many more. To serve your interest on Flow Tester CETATEST 915, kindly contact our sales department.

The CETATEST 915-G is a fully automatic flow test device for the detection of leaking parts. The principle of CETATEST 915-G is quite similar with Flow Tester CETATEST 915 and actually differ only in ranges. They both are using the pressure drop of the laminar flow element (LFE) which then measured by a differential pressure sensor and converted into a flow value. The differential means that the Piezo-resistive gage pressure sensor also measure the actual value by comparing the current measurement of test with allowed parameter setting automatically.

CETATEST 915-G's differential pressure sensor and relative pressure sensor capable of testing pressure ranges from 150 mbar to 600 mbar (other pressures on request). The test is automatically started after adaption of the test part. The CETATEST 915-G method of operation has been specially developed for the gas industry, for reworking in the automobile industry, gas circuit system installation and for reworking in the automobile industry and various other application.

Your investment on Flow Tester CETATEST 915 will lead your way to unlocks higher level of precision in detecting irregularity of flow on both very small to medium ratios of test part volumes on mass production system. The test itself is automatically started after adaption of the test part. With the CETA flow testers, the volume flow through the test part can be measured conveniently. By the use of appropriate laminar flow elements a wide range of flows can also be covered.

Flow Tester CETATEST 915 Features:

- Laminar flow element with differential pressure transducer

- Abilities for direct or indirect test method

- Much cheaper and safer alternative than other NDT method.

- Test pressure sensor is using Piezo-resistive gage pressure sensor

- Flow measurement range is 0 to 2 ml/min resp. 0 to 120 ml/h (depending on the type of the laminar flow element)

- Unit of measurement are ml/min, ml/h, l/min, l/h

- Pressure controller is using both mechanical and electronical method

- Ideal test pressure range are 150 mbar • 600 mbar

- Compact form factor of 345 mm x 145 mm x 435 mm (W x H x D)

- Suitable application Tests of valves, exhaust gas systems, pipes, membranes, automation filling, within the automated cycle of food-beverages packaging industry, pharmaceuticals, medical equipment and many more.

To serve your interest on Flow Tester CETATEST 915,

kindly contact our sales department.

Overview

Customer values

Every CETA Test product is manufactured to the strictest standard of DIN ISO 9001:2008, DIN EN ISO 17025, while its “automatic function control” is registered with patent No. 100 45 472. Your reliability on Ceta Test line of quality instruments are also covered with 3 years of extendable warranty

Built to last

For more than 25 years CETA Testsysteme GmbH has been pioneering physical test instrument for the measurement of leaks and flow rates with gas and air application for various industrial testing. Ceta test's line of innovative instruments are devised for your mass production capabilities

TECHNICAL SPECIFICATION

Flow Tester CETATEST 915-G Ordering Guide:

| Operating methods | CETATEST 915-G Direct laminar flow measurement |

| Signal processing | Fast 24-Bit-A/D-Converter Real time processing of the measurement signals |

| Processing | Real time microcontroller system, 16-Bit µC / 40 MHz |

| Start function | Selectable automatic start |

| Sensors | Differential pressure sensor, relative pressure sensor (test pressure) |

| Measurement range | 0.0 to 120.0 ml/h without or with one position after decimal point [ml/h], 0.00 to 2.00 ml/min with one or two positions after decimal point [ml/min] (other ranges on request) |

| Result units | ml/min, ml/h, l/min, l/h, mbar*l/s |

| Test pressure range | 150 mbar and 600 mbar (other pressures on request) |

| Test mode/Test options | Delay, filling, stabilising, measuring |

| Programmable test phases | Filling pressure Test part specific reject and rework levels |

| Adjustable threshold values | Intuitive menus Password protected user levels |

| Handling | 64 individual parameter driven test programs with alpha-numeric program namesParameters of the test programs can be exported resp. imported via the test device interfaces or by usage of a USB storage device. |

| Parameter memory | 64 individual parameter driven test programs with alpha-numeric program namesParameters of the test programs can be exported resp. imported via the test device interfaces or by usage of a USB storage device |

To serve your interest on Flow Tester CETATEST 915-G,

kindly contact our sales department.

Request a Quote

Request A Quote

Please complete the below form to receive further information.