- Home

- Products

- Cutting Tools

- Drills

- ILIX 6052XB Drill Bit DIN 6537L

If you want to find out more about

ILIX 6052XB Drill Bit DIN 6537L

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

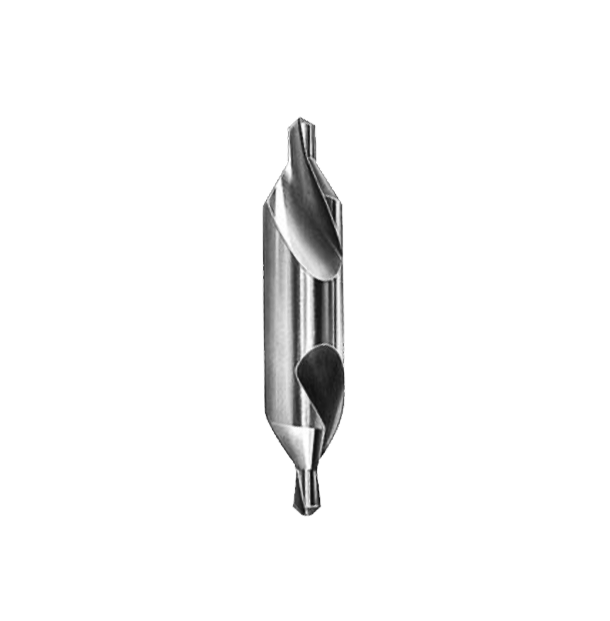

ILIX is the specialist for holemaking and high-precision cutting tools. Ilix offers a wide product range of high-quality, precise and effective products for different tasks; from dry machining with high performances twist drills (VHM) to thread production or reaming even in hundredth increment sizes. Ilix provides highest precision for today’s most demanding applications. ILIX 6114 is a solid carbide drills with straight shank made of HSS. ILIX 6114 drills are made to conform with DIN 6537L standard with the finest HSS cobalt which produces higher toughness and hardness. Depends on your coating selection and cuting speed, you can drill Inconel, Stainless Steel, Titanium with a tensile strength up to 1.000 N/mm2. ILIX 6052XB Drill Bit DIN 6537L Features: Dimensions: Ref. 6052XB DIN 6537L Shank: DIN 6535 HA Material: Solid carbide sub micrograin K 40F (10 - 12% Co) Surface Treatment: TiAIN Multilayers nanocomposite Range: ø mm: 3-16 PDF catalog can be downloaded here (50 MB)

ILIX is the specialist for holemaking and high-precision cutting tools. Ilix offers a wide product range of high-quality, precise and effective products for different tasks; from dry machining with high performances twist drills (VHM) to thread production or reaming even in hundredth increment sizes. Ilix provides highest precision for today’s most demanding applications.

ILIX 6114 is a solid carbide drills with straight shank made of HSS. ILIX 6114 drills are made to conform with DIN 6537L standard with the finest HSS cobalt which produces higher toughness and hardness. Depends on your coating selection and cuting speed, you can drill Inconel, Stainless Steel, Titanium with a tensile strength up to 1.000 N/mm2.

ILIX 6052XB Drill Bit DIN 6537L Features:

- Dimensions: Ref. 6052XB DIN 6537L

- Shank: DIN 6535 HA

- Material: Solid carbide sub micrograin K 40F (10 - 12% Co)

- Surface Treatment: TiAIN Multilayers nanocomposite

- Range: ø mm: 3-16

- PDF catalog can be downloaded here (50 MB)

.png)

Overview

Customer value

ILIX is synonymous with drill and holemaking specialist, a division of Angelo Ghezzi group Italy. ILIX strong reputation for quality cutting tool is supported with over 65K items which are constantly produced at every DIN and ISO standard on various type of coating suitable for your faster rate of procurement.

Built to last

Since 1895, LIX Präzisionswerkzeuge GmbH was pioneering manufaturer of precision twist drills, taps countersinks and reamers. ILIX answer the demands of fabricators with clients of world's ultimate requirements

TECHNICAL SPECIFICATION

Cutting parameters

|

Material |

Vc (m/min) |

Feed f (mm/r) for ø |

|||

|

6052XB |

3 - 5 |

5 - 8 |

8 - 12 |

12 - 16 |

|

|

Stainless, heat and acid resistant steel |

70 |

0.04 - 0.055 |

0.06 - 0.08 |

0.08 - 0.12 |

0.12 - 0.20 |

|

Stainless, austentic, heat and acid resistant steel |

45 |

0.025 - 0.035 |

0.035 - 0.06 |

0.06 - 0.10 |

0.10 - 0.15 |

|

Special alloys based on Ni-Co |

40 |

0.03 - 0.05 |

0.05 - 0.08 |

0.08 - 0.11 |

0.11 - 0.15 |

|

Titanium and titanium alloys up to over 700 N/mm2 |

50 |

0.03 - 0.05 |

0.05 - 0.08 |

0.08 - 0.10 |

0.10 - 0.14 |

These conditions can be applied for continuous cut. In case of cross hole drilling or, with entry and exit on irregular faces or angles, the above mentioned values have to be reduced by 50%. Minimum pressure required is 10 bar.

|

N.cod. |

6052XB |

|

N.Cod. |

6052XB |

|

N.cod. |

6052XB |

|||||||||||||||

|

Type Record |

VA i |

|

Type Record |

VA i |

|

Type Record |

Va i |

|||||||||||||||

|

Cutting direction |

Right hand |

|

Cutting direction |

Right hand |

|

Cutting Direction |

Right hand |

|||||||||||||||

|

Material |

K 40F |

|

Material |

K 40F |

|

Material |

K 40F |

|||||||||||||||

|

ø mm |

l1 |

l2 |

l3 |

l4 |

h6 |

|

|

ø mm |

l1 |

l2 |

l3 |

l4 |

h6 |

|

|

ø mm |

l1 |

l2 |

l3 |

l4 |

h6 |

|

|

3.0 |

66 |

28 |

23 |

36 |

6 |

• |

|

6.7 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.4 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.1 |

66 |

28 |

23 |

36 |

6 |

• |

|

6.8 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.5 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.2 |

66 |

28 |

23 |

36 |

6 |

• |

|

6.9 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.6 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.3 |

66 |

28 |

23 |

36 |

6 |

• |

|

7.0 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.7 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.4 |

66 |

28 |

23 |

36 |

6 |

• |

|

7.1 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.8 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.5 |

66 |

28 |

23 |

36 |

6 |

• |

|

7.2 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.9 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.6 |

66 |

28 |

23 |

36 |

6 |

• |

|

7.3 |

91 |

53 |

43 |

36 |

8 |

• |

|

11.0 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.7 |

66 |

28 |

23 |

36 |

6 |

• |

|

7.4 |

91 |

53 |

43 |

36 |

8 |

• |

|

11.1 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.8 |

74 |

36 |

29 |

36 |

6 |

• |

|

7.5 |

91 |

53 |

43 |

36 |

8 |

• |

|

11.2 |

118 |

71 |

56 |

45 |

12 |

• |

|

3.9 |

74 |

36 |

29 |

36 |

6 |

• |

|

7.6 |

91 |

53 |

43 |

36 |

8 |

• |

|

11.3 |

118 |

71 |

56 |

45 |

12 |

• |

|

4.0 |

74 |

36 |

29 |

36 |

6 |

• |

|

7.7 |

91 |

53 |

43 |

36 |

8 |

• |

|

11.4 |

118 |

71 |

56 |

45 |

12 |

• |

|

4.1 |

74 |

36 |

29 |

36 |

6 |

• |

|

7.8 |

91 |

53 |

43 |

36 |

8 |

• |

|

11.5 |

118 |

71 |

56 |

45 |

12 |

• |

|

4.2 |

74 |

36 |

29 |

36 |

6 |

• |

|

7.9 |

91 |

53 |

43 |

36 |

8 |

• |

|

11.6 |

118 |

71 |

56 |

45 |

12 |

• |

|

4.3 |

74 |

36 |

29 |

36 |

6 |

• |

|

8.0 |

91 |

53 |

43 |

36 |

8 |

• |

|

11.7 |

118 |

71 |

56 |

45 |

12 |

• |

|

4.4 |

74 |

36 |

29 |

36 |

6 |

• |

|

8.1 |

103 |

61 |

49 |

40 |

10 |

• |

|

11.8 |

118 |

71 |

56 |

45 |

12 |

• |

|

4.5 |

74 |

36 |

29 |

36 |

6 |

• |

|

8.2 |

103 |

61 |

49 |

40 |

10 |

• |

|

11.9 |

118 |

71 |

56 |

45 |

12 |

• |

|

4.6 |

74 |

36 |

29 |

36 |

6 |

• |

|

8.3 |

103 |

61 |

49 |

40 |

10 |

• |

|

12.0 |

118 |

71 |

56 |

45 |

12 |

• |

|

4.7 |

74 |

36 |

29 |

36 |

6 |

• |

|

8.4 |

103 |

61 |

49 |

40 |

10 |

• |

|

12.5 |

124 |

77 |

60 |

45 |

14 |

• |

|

4.8 |

82 |

44 |

35 |

36 |

6 |

• |

|

8.5 |

103 |

61 |

49 |

40 |

10 |

• |

|

13.0 |

124 |

77 |

60 |

45 |

14 |

• |

|

4.9 |

82 |

44 |

35 |

36 |

6 |

• |

|

8.6 |

103 |

61 |

49 |

40 |

10 |

• |

|

13.5 |

124 |

77 |

60 |

45 |

14 |

• |

|

5.0 |

82 |

44 |

35 |

36 |

6 |

• |

|

8.7 |

103 |

61 |

49 |

40 |

10 |

• |

|

14.0 |

124 |

77 |

60 |

45 |

14 |

• |

|

5.1 |

82 |

44 |

35 |

36 |

6 |

• |

|

8.8 |

103 |

61 |

49 |

40 |

10 |

• |

|

14.5 |

133 |

83 |

63 |

48 |

16 |

• |

|

5.2 |

82 |

44 |

35 |

36 |

6 |

• |

|

8.9 |

103 |

61 |

49 |

40 |

10 |

• |

|

15.0 |

133 |

83 |

63 |

48 |

16 |

• |

|

5.3 |

82 |

44 |

35 |

36 |

6 |

• |

|

9.0 |

103 |

61 |

49 |

40 |

10 |

• |

|

15.5 |

133 |

83 |

63 |

48 |

16 |

• |

|

5.4 |

82 |

44 |

35 |

36 |

6 |

• |

|

9.1 |

103 |

61 |

49 |

40 |

10 |

• |

|

16.0 |

133 |

83 |

63 |

48 |

16 |

• |

|

5.5 |

82 |

44 |

35 |

36 |

6 |

• |

|

9.2 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

||

|

5.6 |

82 |

44 |

35 |

36 |

6 |

• |

|

9.3 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

|

|

|

5.7 |

82 |

44 |

35 |

36 |

6 |

• |

|

9.4 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

|

|

|

5.8 |

82 |

44 |

35 |

36 |

6 |

• |

|

9.5 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

|

|

|

5.9 |

82 |

44 |

35 |

36 |

6 |

• |

|

9.6 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

|

|

|

6.0 |

82 |

44 |

35 |

36 |

6 |

• |

|

9.7 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

|

|

|

6.1 |

91 |

53 |

43 |

36 |

8 |

• |

|

9.8 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

|

|

|

6.2 |

91 |

53 |

43 |

36 |

8 |

• |

|

9.9 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

|

|

|

6.3 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.0 |

103 |

61 |

49 |

40 |

10 |

• |

|

|

|

|

|

|

|

|

|

6.4 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.1 |

118 |

71 |

56 |

45 |

12 |

• |

|

|

|

|

|

|

|

|

|

6.5 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.2 |

118 |

71 |

56 |

45 |

12 |

• |

|

|

|

|

|

|

|

|

|

6.6 |

91 |

53 |

43 |

36 |

8 |

• |

|

10.3 |

118 |

71 |

56 |

45 |

12 |

• |

|

|

|

|

|

|

|

|

Request a Quote

Request A Quote

Please complete the below form to receive further information.