- Home

- Products

- Cutting Tools

- Drills

- Maykestag ALUNIT Shell End Mills DIN 1880

If you want to find out more about

Maykestag ALUNIT Shell End Mills DIN 1880

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

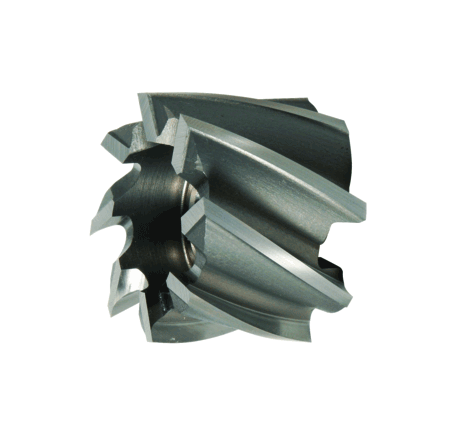

Maykestag ALUNIT Shell End Mill conform with DIN 1880 Maykestag ALUNIT Shell End Mill is also known as fraser cutter is manufactured with extremely tight manufacturing tolerances by utilisation of most modern CNC-grinding technologies. Maykestag ALUNIT Shell End Mill series are made of Austrian HSS micro-grain-carbide and ALUNIT® = super hard coating TiAlN with coating thickness: 3–5 μm, Micro hardness: 3600 HV which produces higher toughness, hardness and bending strength. Maykestag ALUNIT Shell End Mill is manufactured with the most up-to-date metallurgic infuser technology of 5% cobalt-alloyed high speed steel for your stability and wear resistance by its constant tool hardening by computer controlled vacuum heat treatment. The Maykestag's optimised tool geometry provides higher tool stability (even in unstable working conditions) and a higher surface quality of the material to be machined. Maykestag Shell End Mills DIN 1880 also available with TiN coating and uncoated model for affordable alternative in cutting ferrous material. Maykestag ALUNIT Shell End Mill is highly recommended for milling in heavy duty materials up to a tensile strength of 1.300 N/mm2 as well as in rust- and acid-resistant steels, titanium-alloyed materials and similar application range from face milling on Titanium blocks, heavy duty hinges, tool and die fabrication and many more. Maykestag ALUNIT Shell End Mills DIN 1880 Features: Special model and tool geometries are available for each machining problem Reduced coefficient of friction ALUNIT coating lower heat load , decreased wear of the clearance land Increase of cutting speed compared to regular HSS-Co Higher productivity and improved workpiece quality Can also be resharpened due to its non insert technology.

Maykestag ALUNIT Shell End Mill conform with DIN 1880

Maykestag ALUNIT Shell End Mill is also known as fraser cutter is manufactured with extremely tight manufacturing tolerances by utilisation of most modern CNC-grinding technologies. Maykestag ALUNIT Shell End Mill series are made of Austrian HSS micro-grain-carbide and ALUNIT® = super hard coating TiAlN with coating thickness: 3–5 μm, Micro hardness: 3600 HV which produces higher toughness, hardness and bending strength.

Maykestag ALUNIT Shell End Mill is manufactured with the most up-to-date metallurgic infuser technology of 5% cobalt-alloyed high speed steel for your stability and wear resistance by its constant tool hardening by computer controlled vacuum heat treatment. The Maykestag's optimised tool geometry provides higher tool stability (even in unstable working conditions) and a higher surface quality of the material to be machined. Maykestag Shell End Mills DIN 1880 also available with TiN coating and uncoated model for affordable alternative in cutting ferrous material.

Maykestag ALUNIT Shell End Mill is highly recommended for milling in heavy duty materials up to a tensile strength of 1.300 N/mm2 as well as in rust- and acid-resistant steels, titanium-alloyed materials and similar application range from face milling on Titanium blocks, heavy duty hinges, tool and die fabrication and many more.

Maykestag ALUNIT Shell End Mills DIN 1880 Features:

- Special model and tool geometries are available for each machining problem

- Reduced coefficient of friction

- ALUNIT coating lower heat load , decreased wear of the clearance land

- Increase of cutting speed compared to regular HSS-Co

- Higher productivity and improved workpiece quality

- Can also be resharpened due to its non insert technology.

Overview

Customer value

ALPEN-MAYKESTAG manufactures quality drills to conforms with EN ISO 9001 since 2001. The highest quality standards from maykestag products will deliver you the efficient cost in overall and empower you to take on a job with higher precision on tougher material.

Built to perfoms

For over 60 years, ALPEN-MAYKESTAG GmbH manufacture the sharpest series of cutting tools with high-quality carbide and HSS material. Maykestag competencies lie in the development and production of drills, milling cutters, reamers, countersinks, rotary burrs and tools for specialist.

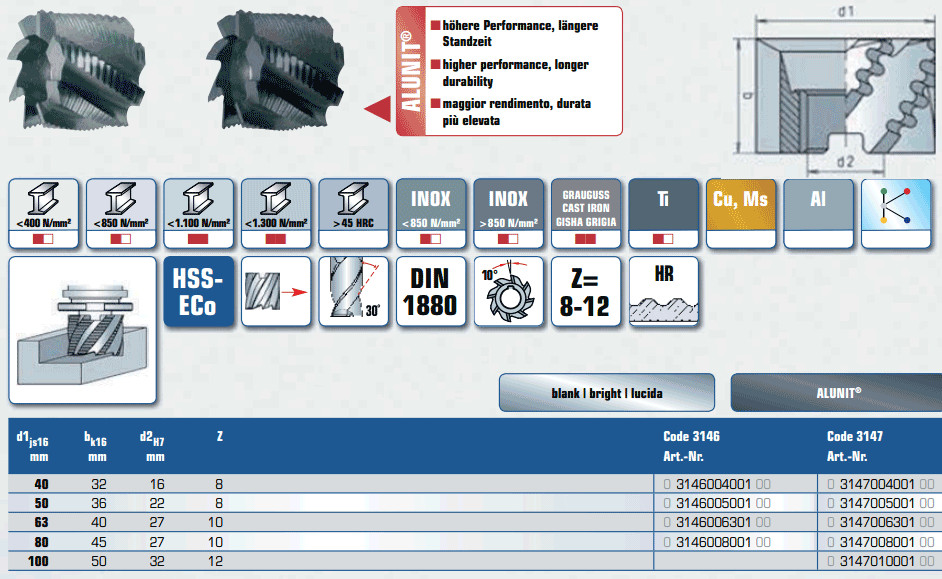

TECHNICAL SPECIFICATION

Maykestag ALUNIT Shell End Mills DIN 1880

Request a Quote

Request A Quote

Please complete the below form to receive further information.