If you want to find out more about

Kinkelder Circular Saw HSS X-treme 2.0

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

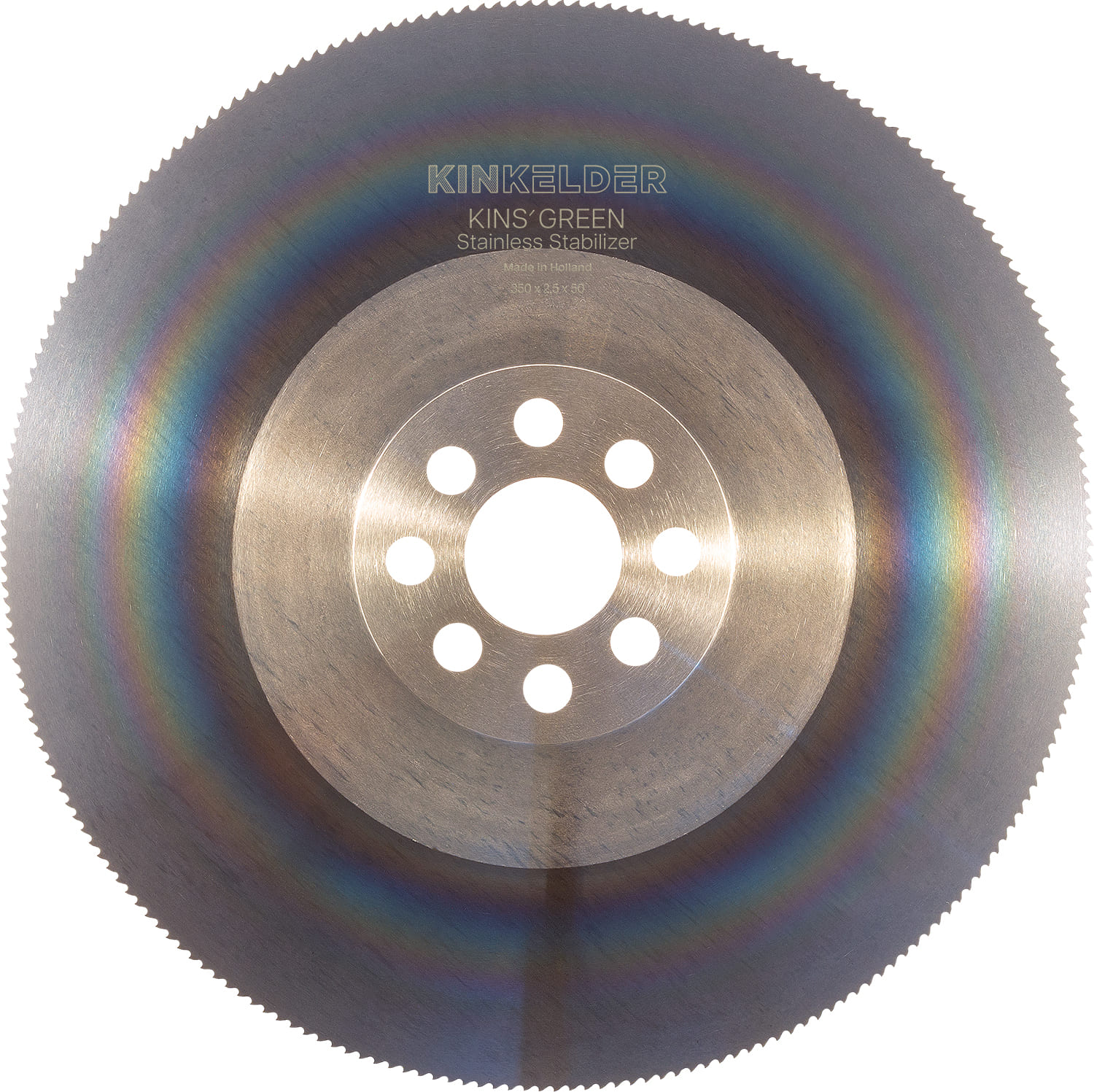

Kinkelder X-treme 2.0 embodies the best features of both the Fusion and Power saw blades. Due to a stable, flat hub and improved conicity of the cutting area, X-treme 2.0 saw blades offer a stable and highly accurate solution when cutting high-tensile steel tubes and profiles on a very high-performance level. Kinkelder HSS X-treme 2.0 features : Stable flat hub for high stability and accuracy Extremely narrow tolerances in blade thickness Optimized surface finish Low friction coefficient Very high-temperature resistance Improved blade tensions More regrinds per blade, therefore lower cost per cut Narrow tolerances in side run-out To be used with a spray mist or emulsion coolant for maximal results For relevant applications, a recoating program is available Kinkelder HSS X-treme 2.0 User Benefits : The best solution for cutting stainless steel tubes Minimizes tube spinning and deformation Improves yields, especially important when cutting expensive materials Kinkelder HSS X-treme 2.0 Applications: Cutting steel tubes and profiles with a tensile strength of up to 1000 N/mm2 Suggested cutting speed: 120 – 260 m/min Feed: 0.04 – 0.22 mm/tooth. Machines: High-quality automatic

Kinkelder X-treme 2.0 embodies the best features of both the Fusion and Power saw blades. Due to a stable, flat hub and improved conicity of the cutting area, X-treme 2.0 saw blades offer a stable and highly accurate solution when cutting high-tensile steel tubes and profiles on a very high-performance level.

Kinkelder HSS X-treme 2.0 features :

- Stable flat hub for high stability and accuracy

- Extremely narrow tolerances in blade thickness

- Optimized surface finish

- Low friction coefficient

- Very high-temperature resistance

- Improved blade tensions

- More regrinds per blade, therefore lower cost per cut

- Narrow tolerances in side run-out

- To be used with a spray mist or emulsion coolant for maximal results

- For relevant applications, a recoating program is available

Kinkelder HSS X-treme 2.0 User Benefits :

- The best solution for cutting stainless steel tubes

- Minimizes tube spinning and deformation

- Improves yields, especially important when cutting expensive materials

Kinkelder HSS X-treme 2.0 Applications:

- Cutting steel tubes and profiles with a tensile strength of up to 1000 N/mm2

- Suggested cutting speed: 120 – 260 m/min

- Feed: 0.04 – 0.22 mm/tooth.

- Machines: High-quality automatic

Overview

Build to last

Customer Value

TECHNICAL SPECIFICATION

Request a Quote

Request A Quote

Please complete the below form to receive further information.