If you want to find out more about

Kinkelder Circular Saw HSS X-treme NX

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

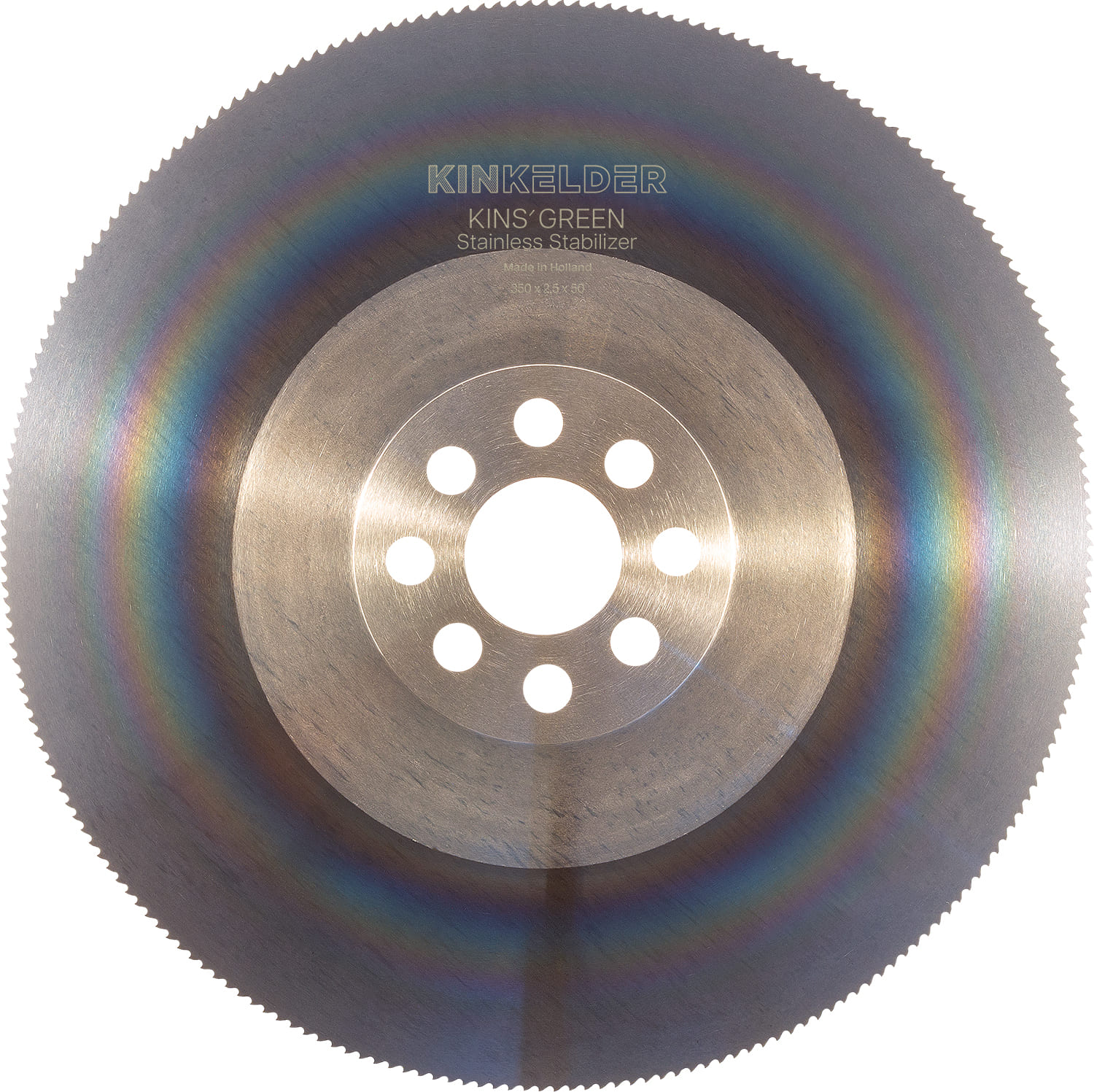

Kinkelder HSS X-treme NX dedicated low friction, thin PVD coating with very high-temperature resistance, as well as a stable, flat hub and improved conicity of the cutting area enable to cut stainless steel tubes and profiles. The X-treme series offers an optimized surface finish, low variations in blade thickness, and a small side runout. The NX coating is designed for cutting stainless steel but also can be used for dedicated steel-cutting applications. Kinkelder HSS X-treme NX features : Thin PVD coating, specifically designed for cutting stainless steel Extremely narrow tolerances in blade thickness Optimized surface finish The very low friction coefficient Improved blade tensions Narrow tolerances in side run-out High-temperature resistance Stable flat hub for high stability To be used with a spray mist or emulsion coolant for maximal results For relevant applications, a recoating program is available Kinkelder HSS X-treme NX User Benefits : The best solution for cutting stainless steel tubes Minimizes tube spinning and deformation Improves yields, especially important when cutting expensive materials Kinkelder HSS X-treme NX Applications: (Stainless) steel tubes, profiles and sticky materials Suggested cutting speed:Austenitic stainless steel (300 series) 30 – 50 m/minFerritic w/o Ti (409 & 412) 220 – 260 m/minFerritic with Ti (441) 60 – 120 m/min Machines: High-quality automatic

Kinkelder HSS X-treme NX dedicated low friction, thin PVD coating with very high-temperature resistance, as well as a stable, flat hub and improved conicity of the cutting area enable to cut stainless steel tubes and profiles. The X-treme series offers an optimized surface finish, low variations in blade thickness, and a small side runout. The NX coating is designed for cutting stainless steel but also can be used for dedicated steel-cutting applications.

Kinkelder HSS X-treme NX features :

- Thin PVD coating, specifically designed for cutting stainless steel

- Extremely narrow tolerances in blade thickness

- Optimized surface finish

- The very low friction coefficient

- Improved blade tensions

- Narrow tolerances in side run-out

- High-temperature resistance

- Stable flat hub for high stability

- To be used with a spray mist or emulsion coolant for maximal results

- For relevant applications, a recoating program is available

Kinkelder HSS X-treme NX User Benefits :

- The best solution for cutting stainless steel tubes

- Minimizes tube spinning and deformation

- Improves yields, especially important when cutting expensive materials

Kinkelder HSS X-treme NX Applications:

- (Stainless) steel tubes, profiles and sticky materials

- Suggested cutting speed:

Austenitic stainless steel (300 series) 30 – 50 m/min

Ferritic w/o Ti (409 & 412) 220 – 260 m/min

Ferritic with Ti (441) 60 – 120 m/min - Machines: High-quality automatic

Overview

Build to last

Customer Value

TECHNICAL SPECIFICATION

Request a Quote

Request A Quote

Please complete the below form to receive further information.