If you want to find out more about

Koyo-Sha Titanium Buffing & Polishing Compound

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Koyo-Sha Buffing & Polishing compound have wide varieties and selection to choose from. Titanium which was previously difficult to have a luster finish, can easily be polished to surface equivalent with #400 and #600 finish of stainless steel. With the right sisal and buffing disc, each Koyo-sha Buffing & Polishing compound will perform superbly on polishing titanium. Prior to polishing, titanium work piece that is severely scratched may need to be sanded down. Once the scratch depth is minimal, it is advised to start with the coarsest compound that is applicable such as Koyo-Sha's TP-100. From there one should than move down to the next buffing compound such as Koyo-Sha TP-401 and so on until the desired finish is achieved. Koyo-sha Buffing & Polishing Compound For Titanium Are As Follows: 1. TP-100 A polishing compound which is designed by attaching greater importance in high cutting power, and it shows much effect in a process of removing scratches and waves of materials. by using TP-200 compound after this stage, cloth buff finish will be easier. 2. TP-200 A polishing compound of good balance of cutting and coloring. It is considered as a standard product for sisal buff. suitable for cutting and coloring to get a smooth surface without pin holes. 3. C-800 4. TP-300 An indispensable polishing compound for a process of luster finish. it removes sisal patterns smoothly, and a luster surface equivalent to #400 finish of stainless steel can be obtained. 5. TP-401 It prevents works to have pin holes and buff scratches during a "green rouge compound finish" process, while polishing at high load. by using TP-401, a luster surface with a high reflection rate equivalent to #600 finish of stainless steel can be obtained. For further details on Koyo-Sha Titanium Buffing & Polishing Compound, kindly contact our sales department.

Koyo-Sha Buffing & Polishing compound have wide varieties and selection to choose from. Titanium which was previously difficult to have a luster finish, can easily be polished to surface equivalent with #400 and #600 finish of stainless steel. With the right sisal and buffing disc, each Koyo-sha Buffing & Polishing compound will perform superbly on polishing titanium.

Prior to polishing, titanium work piece that is severely scratched may need to be sanded down. Once the scratch depth is minimal, it is advised to start with the coarsest compound that is applicable such as Koyo-Sha's TP-100. From there one should than move down to the next buffing compound such as Koyo-Sha TP-401 and so on until the desired finish is achieved.

Koyo-sha Buffing & Polishing Compound For Titanium Are As Follows:

.jpg) |

|

||||||||||

For further details on Koyo-Sha Titanium Buffing & Polishing Compound,

kindly contact our sales department.

Overview

Customer value

Built to last

TECHNICAL SPECIFICATION

Koyo-sha Buffing & Polishing Compound On Application Are As Follows:

| For Sisal Buff: |

It prevents works from having burn marks, that are easily brought about during a cutting process, and made it possible to have efficient polishing. It shows the greatest effect when used with open sisal buffs. |

| For Cloth Buff: | Titanium which was said to be difficult to have a luster finish can easily be finished up to surface equivalent to #400 and #600 finish of stainless steel. |

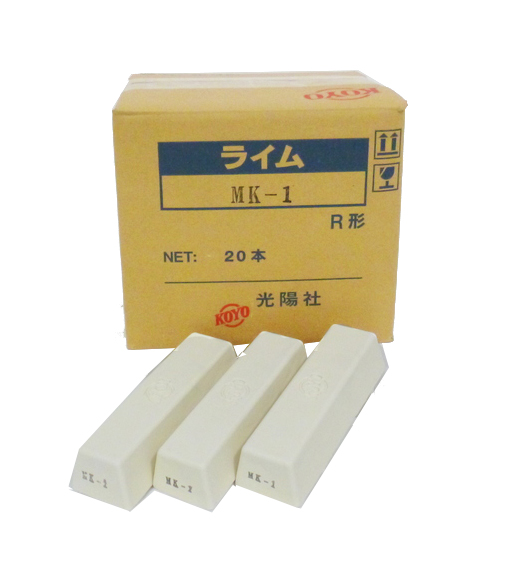

Koyo-sha Buffing & Polishing Compound:

| Solid Compound | Characteristics / Application | ||||

| Product Name | Color | Pcs/ Box |

|||

|

Buffing Polishing Compound For Cutting ⇑ ⇑ ⇑ ⇓ ⇓ ⇓

Buffing

Polishing

Compound

For Coloring |

TP-100 | Black | 25 | For cutting on sisal buffs / high cutting power good for removing waves and scratches of materials | |

| TP-200 | Gray | 25 | Suitable for cutting and coloring on sisal buffs good balance of cutting and coloring makes a surface without pin holes | ||

| C-800 | Black | 30 | On sisal buffs for cutting and coloring has good cutting power / suitable for sisal finish | ||

| TP-300 | Beige | 30 | On cloth buffs for cutting and coloring / removes sisal marks can obtain a surface equivalent to #400 finish of stainless steel | ||

| TP-401 | White | 30 | On cloth buffs for coloring / removes pin holes and buff scratches, and gives a lustrous surface equivalent to #600 finish of stainless steel | ||

| SUPER ALOX | Yellow | 30 | On cloth buffs for coloring / removes pin holes and buff scratches, and gives a lustrous surface equivalent to #600 finish of stainless steel (especially for titanium alloy, super alox creates more lustrous surface than TP-401) | ||

Contact us for more information on Koyo-Sha Buffing & Polishing Compound,

Request a Quote

Request A Quote

Please complete the below form to receive further information.