- Home

- Products

- Abrasives

- Polishing & Lustering

- Koyo-Sha Uniflap Wheel Abrasive Cloth

If you want to find out more about

Koyo-Sha Uniflap Wheel Abrasive Cloth

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

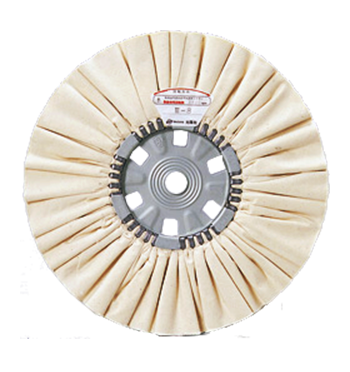

Started in Tokyo 1926, Koyo-Sha manufactures the finest standard of polishing and finishing solution for various industrial application. The Koyo-Sha product ranges adhere to ISO9001 and ISO14001 to meet your strictest quality assurance and fabrication standards. Koyo-Sha's uniquely finger-shaped equipment will surely shorten your working hours. With its high sanding performance, amazing effect will be obtained. Koyo-Sha Uniflap works better to replace any emery wheels for metal surface polishing of stainless steel, aluminum ware, and other wide range of metal. The Koyo-Sha Uniflap wheel are commonly used in aerospace industry, CNC fabrication, piping and tank container fabrication. Koyo-Sha Uniflap Wheel Features: As to A-type and R-type, section lines are not marked on works as fingers are mounted in zigzag form. Uniflap will surely shorten your working hours with its high sanding performance, and your fatigue is also diminished. As to B-type, fingers are mounted in a straight line, so it fits well to grooves of works. Its excellent elasticity let it fit not only to flat surfaces but also to irregular surfaces. Especially, R-type has an excellent elasticity because of the open round shape of each finger. Frequent replacement like in operations with abrasive belts or emery wheels (iron buff) is not necessary because Uniflap can be used to the last end. Uniflap can be used, in the same manner as our cloth buffs, to wide range of works. Uniflap can stand against operations with strong pressure, they can be set to automatic machines. Surface Roughness of Koyo-Sha Uniflap Wheel As a substitute tool of emery buff, Uniflap's polishing streaks are more similar to emery buff's than KF wheel's. By applying tripoli, the surface roughness becomes finer, and can be used in the pre-buffing process. But the polishing streaks of Uniflap (#400) is coaser than that of emery buff (#250 or #320) when emery buff is applied with tripoli.

Started in Tokyo 1926, Koyo-Sha manufactures the finest standard of polishing and finishing solution for various industrial application. The Koyo-Sha product ranges adhere to ISO9001 and ISO14001 to meet your strictest quality assurance and fabrication standards.

Koyo-Sha's uniquely finger-shaped equipment will surely shorten your working hours. With its high sanding performance, amazing effect will be obtained. Koyo-Sha Uniflap works better to replace any emery wheels for metal surface polishing of stainless steel, aluminum ware, and other wide range of metal. The Koyo-Sha Uniflap wheel are commonly used in aerospace industry, CNC fabrication, piping and tank container fabrication.

Koyo-Sha Uniflap Wheel Features:

- As to A-type and R-type, section lines are not marked on works as fingers are mounted in zigzag form. Uniflap will surely shorten your working hours with its high sanding performance, and your fatigue is also diminished. As to B-type, fingers are mounted in a straight line, so it fits well to grooves of works.

- Its excellent elasticity let it fit not only to flat surfaces but also to irregular surfaces. Especially, R-type has an excellent elasticity because of the open round shape of each finger.

- Frequent replacement like in operations with abrasive belts or emery wheels (iron buff) is not necessary because Uniflap can be used to the last end.

- Uniflap can be used, in the same manner as our cloth buffs, to wide range of works.

- Uniflap can stand against operations with strong pressure, they can be set to automatic machines.

Surface Roughness of Koyo-Sha Uniflap Wheel

As a substitute tool of emery buff, Uniflap's polishing streaks are more similar to emery buff's than KF wheel's. By applying tripoli, the surface roughness becomes finer, and can be used in the pre-buffing process. But the polishing streaks of Uniflap (#400) is coaser than that of emery buff (#250 or #320) when emery buff is applied with tripoli.

Overview

TECHNICAL SPECIFICATION

Koyo-Sha Uniflap Wheel

.jpg)

*Cloth type : JAU

.*Please follow the rotational speed standard of conventional buffing wheels in use.

Batam karimun sumatera medan palembang bintan tanjung uban batamindo lampung johor singapore malaysia riau kepulauan riau industrial grinding abrasive polishing finishing buffing Felt industrial grinding abrasive polishing finishing buffing Felt malaysia riau kepulauan riau industrial grinding abrasive polishing finishing buffing Felt industrial grinding abrasive polishing finishing buffing Felt malaysia riau kepulauan riau industrial grinding abrasive polishing finishing buffing Felt industrial grinding abrasive polishing finishing buffing Felt malaysia riau kepulauan riau industrial grinding abrasive polishing finishing buffing Felt industrial grinding abrasive polishing finishing industrial grinding abrasive polishing finishing buffing Felt industrial grinding abrasive polishing finishing industrial grinding abrasive polishing finishing buffing Felt industrial buffing Felt industrial grinding abrasive polishing finishing industrial grinding abrasive polishing finishing buffing abrasive polishing finishing buffing Felt industrial buffing Felt industrial grinding abrasive

Koyo-Sha's Common Buffing And Compounds Combination Guide:

The following chart will help in deciding which wheels and compounds to use when polishing different materials.

This chart is a starting point and experienced polishers may vary the materials used to suit different applications.

| Plastics | Silver, gold & thin plates | Nickel & chrome plating | Copper, brass, aluminium, pot metal & soft metals | Steel & iron | Stainless steel | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Buff type | Rough | Initial buff | Final buff | Rough | Initial buff | Final buff | Rough | Initial buff | Final buff | Rough | Initial buff | Final buff | Rough | Initial buff | Final buff | Rough | Initial buff | Final buff |

| Sisal | X | X | X | |||||||||||||||

| Spiral sewn | X | X | X | X | ||||||||||||||

| Loose | X | X | X | |||||||||||||||

| Canton flannel | X | X | ||||||||||||||||

| String | X | X | X | |||||||||||||||

| Compound | ||||||||||||||||||

| Black | X | X | X | |||||||||||||||

| Brown | X | |||||||||||||||||

| White | X | X | X | |||||||||||||||

| Blue | X | X | X | X | X | X | ||||||||||||

| Green | X | X | ||||||||||||||||

| Red | X | X | X | |||||||||||||||

-

BLACK = Emery Compound, a coarse abrasive material for removal of scratches, pits, paint, rust etc.

BROWN = Tripoli compound used for general purpose cut and color on most soft metals.

WHITE = Blizzard compound, used for color and final finish of harder metals, has a cutting action.

RED = Jeweller’s Rouge, designed to polish without any cutting action. Safe on thin plates. Use on its own wheel.

BLUE = A dryer, almost greaseless wheel - designed to polish without any cutting action. Safe on thin plates. Use on its own wheel.

GREEN = Used exclusively for Stainless Steel.

-

abrasive polishing finishing buffing Felt industrial buffing Felt industrial grinding abrasive polishing finishing industrial grinding abrasive polishing finishing buffing abrasive polishing finishing buffing Felt industrial buffing Felt industrial grinding abrasive polishing finishing industrial grinding abrasive polishing finishing buffing abrasive polishing finishing buffing Felt industrial buffing Felt industrial grinding abrasive

To serve your interest on Koyo-Sha solution,

kindly contact our sales department

Request a Quote

Request A Quote

Please complete the below form to receive further information.