- Home

- Products

- Cutting Tools

- End Mills / Slot Drill

- Magafor Miniature End Mill Tool 8529-H-33

If you want to find out more about

Magafor Miniature End Mill Tool 8529-H-33

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

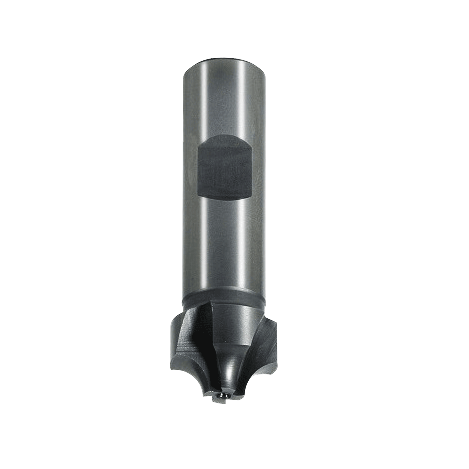

Magafor Micro-Milling - Miniature Ball-End End-Mills | Hard'X Coated Carbide Standard Series Miniature Ball-End End-Mills | Hard’X Coated Carbide Standard Series Miniature Ball-End End-Mills – 85290550-H The Magafor Micro End Mill Tool 8529-H-33 are manufactured with Hard’X coating (AITiN) with a high hardness (3,700 Hv). This coating shows a high thermic stability and an excellent protection against heat and wear. The Magafor Micro End Mill Tool 8529-H-33 are ideal for dry machining – high speed cutting – in treated steels and dies. The higher concentration of aluminum in the coating creates for a lower friction coefficient which inturn, improves greater tool life than traditional TiAIN offerings. Furthermore, Magafor micro toolings have specific design for each of your machining applications. Magafor styles, materials and lengths can also be custom ordered to meet varying application within specific machining technic. Magafor Micro End Mill Tool 8529-H-33 Features: Micro milling capabilities suitable for all direction cut at micron precision ranges from mould fabrication, coin making, sheet of metal working etcetera. Their reinforced shank offers a greater stability necessary to these high precision tools. Ball end designs with AITIN coating which is realiably proven for its faster rates of removal on dry milling or harder composition of workpiece. Also available with Carbide standard series for soft metal and plastic and Graph'x Series for medium metal and ceramics

Magafor Micro-Milling - Miniature Ball-End End-Mills | Hard'X Coated Carbide Standard Series Miniature Ball-End End-Mills | Hard’X Coated Carbide Standard Series Miniature Ball-End End-Mills – 85290550-H

The Magafor Micro End Mill Tool 8529-H-33 are manufactured with Hard’X coating (AITiN) with a high hardness (3,700 Hv). This coating shows a high thermic stability and an excellent protection against heat and wear. The Magafor Micro End Mill Tool 8529-H-33 are ideal for dry machining – high speed cutting – in treated steels and dies.

The higher concentration of aluminum in the coating creates for a lower friction coefficient which inturn, improves greater tool life than traditional TiAIN offerings. Furthermore, Magafor micro toolings have specific design for each of your machining applications. Magafor styles, materials and lengths can also be custom ordered to meet varying application within specific machining technic.

Magafor Micro End Mill Tool 8529-H-33 Features:

- Micro milling capabilities suitable for all direction cut at micron precision ranges from mould fabrication, coin making, sheet of metal working etcetera.

- Their reinforced shank offers a greater stability necessary to these high precision tools.

- Ball end designs with AITIN coating which is realiably proven for its faster rates of removal on dry milling or harder composition of workpiece.

- Also available with Carbide standard series for soft metal and plastic and Graph'x Series for medium metal and ceramics

Overview

Customer value

Magafor manufactures more than 250 product groups of mini cutting and detailed toolings solution in European Union. Magafor have produced even the smallest drills of 0.40mm diameter micro end-mill which are available in 26 different lengths and designs.

Built to perfoms

Since 1937, Magafor manufactures over 6,000 standard items of cutting tool solutions in France. Magafor's main expertise is micro cutting for machining and carving on various material such as metal, ceramics, minerals and even in the field of orthodentistry.

TECHNICAL SPECIFICATION

Magafor Micro End Mill Tool Material Application Guide:

Magafor Micro End Mill Tool 8529-H-33:

| Item # | 85290550-H |

| D Diameter | .2165" |

| d2 Shank | .236" |

| L Length | 2" |

| \ Flute Length | .550" |

| Series Code | 8529-H |

| Material | Hard'X |

| R | .1083" |

| R Tolerance | 0 - .0004" |

Magafor Micro End Mill Tool 8529-H-33 Technical Dimension:

:

:

Magafor Micro End Mill Tool 8529-H-33 Ordering Guide:

| Item # | D Diameter | d2 Shank | L Length | \ Flute Length |

|---|---|---|---|---|

| 85290030-H | .0118" | .118" | 1 1/2" | .040" |

| 85290035-H | .0138" | .118" | 1 1/2" | .040" |

| 85290040-H | .0157" | .118" | 1 1/2" | .040" |

| 85290050-H | .0197" | .118" | 1 1/2" | .060" |

| 85290060-H | 0.0236" | .118" | 1 1/2" | .060" |

| 85290070-H | 0.0276" | .118" | 1 1/2" | .080" |

| 85290080-H | 0.0315" | .118" | 1 1/2" | .080" |

| 85290090-H | 0.0354" | .118" | 1 1/2" | .100" |

| 85290100-H | 0.0394" | .118" | 1 1/2" | .120" |

| 85290110-H | 0.0433" | .118" | 1 1/2" | .120" |

| 85290120-H | .0472" | .118" | 1 1/2" | .160" |

| 85290140-H | .0551" | .118" | 1 1/2" | .160" |

| 85290150-H | .0591" | .118" | 1 1/2" | .160" |

| 85290160-H | .0630" | .118" | 1 1/2" | .160" |

| 85290180-H | .0709" | .118" | 1 1/2" | .200" |

| 85290200-H | .0787" | .118" | 1 1/2" | .200" |

| 85290250-H | .0984" | .118" | 1 1/2" | .275" |

| 85290300-H | .1181" | .157" | 1 3/4" | .400" |

| 85290350-H | .1378" | .157" | 1 3/4" | .400" |

| 85290400-H | .1575" | .197" | 2" | .475" |

| 85290450-H | .1772" | .197" | 2" | .475" |

| 85290500-H | .1968" | .236" | 2" | .550" |

| 85290550-H | .2165" | .236" | 2" | .550" |

Request a Quote

Request A Quote

Please complete the below form to receive further information.