- Home

- Products

- Accessories

- Inspection Stage

- Miruc Dovetail Feed Screw Stage

If you want to find out more about

Miruc Dovetail Feed Screw Stage

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Since 1963, MIRUC OPTICAL CO.,LTD. have been manufacturing optical peripheral and special equipment to cater both research and industrial needs of visual magnification with measurement capabilities in Japan. Miruc Dovetail Feed Screw Stage are operated by differential screw mechanism used for making small, precise adjustments to stage similar with focusing the magnification in microscope, moving the anvils of a micrometer, or positioning optics. A differential screw uses a spindle with two screw threads of differing leads (aka thread pitch), and possibly opposite handedness, on which two nuts move. As the spindle rotates, the space between the nuts changes based on the difference between the threads. Miruc Dovetail Feed Screw Stage are equipped with scale and revolutionary feed screw lens stage which allows you to select a single rotation of the handle to be set to move by 2 mm, 5 mm or 10 mm. These mechanisms allow extremely small adjustments using commonly available screws. With an easily visible central divider type color scale, the scale and clamp lever can easily be detached and switched from left to right, thus a symmetrically opposite arrangement is simple to make. As optional extras, two handled types, extension handle types and two set parallel types are available. The multi-function feed screw type has a rich array of features, providing long strokes at a regular pitch and with smooth sliding action, extremely useful for application in environments with limited space. Miruc Dovetail Feed Screw Stage Mechanism: Rotating a bolt through two nuts with slightly different thread pitches for each changes the separation of the nuts by the difference between the threads.

Since 1963, MIRUC OPTICAL CO.,LTD. have been manufacturing optical peripheral and special equipment to cater both research and industrial needs of visual magnification with measurement capabilities in Japan.

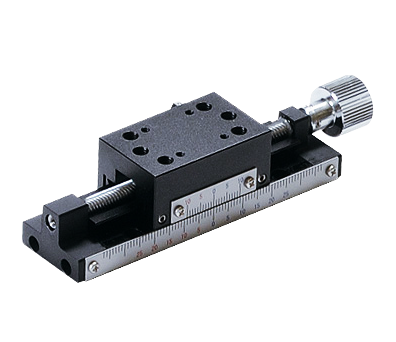

Miruc Dovetail Feed Screw Stage are operated by differential screw mechanism used for making small, precise adjustments to stage similar with focusing the magnification in microscope, moving the anvils of a micrometer, or positioning optics. A differential screw uses a spindle with two screw threads of differing leads (aka thread pitch), and possibly opposite handedness, on which two nuts move. As the spindle rotates, the space between the nuts changes based on the difference between the threads.

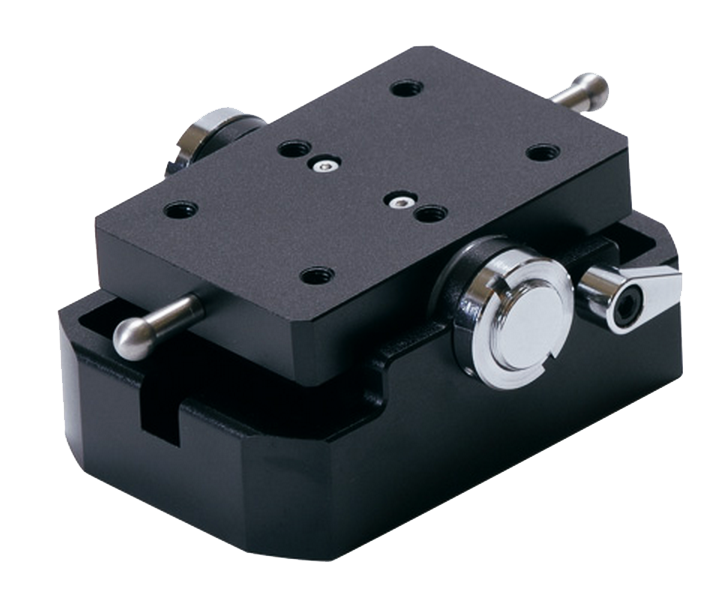

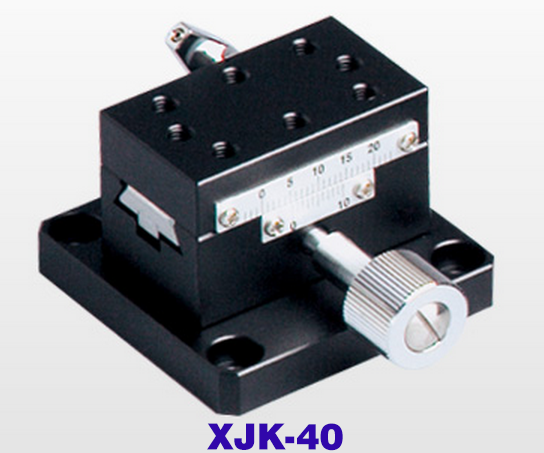

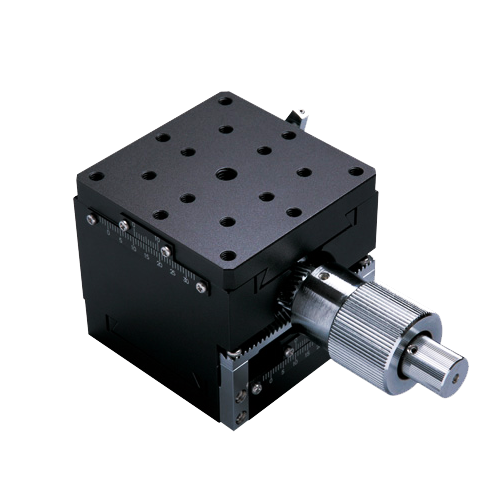

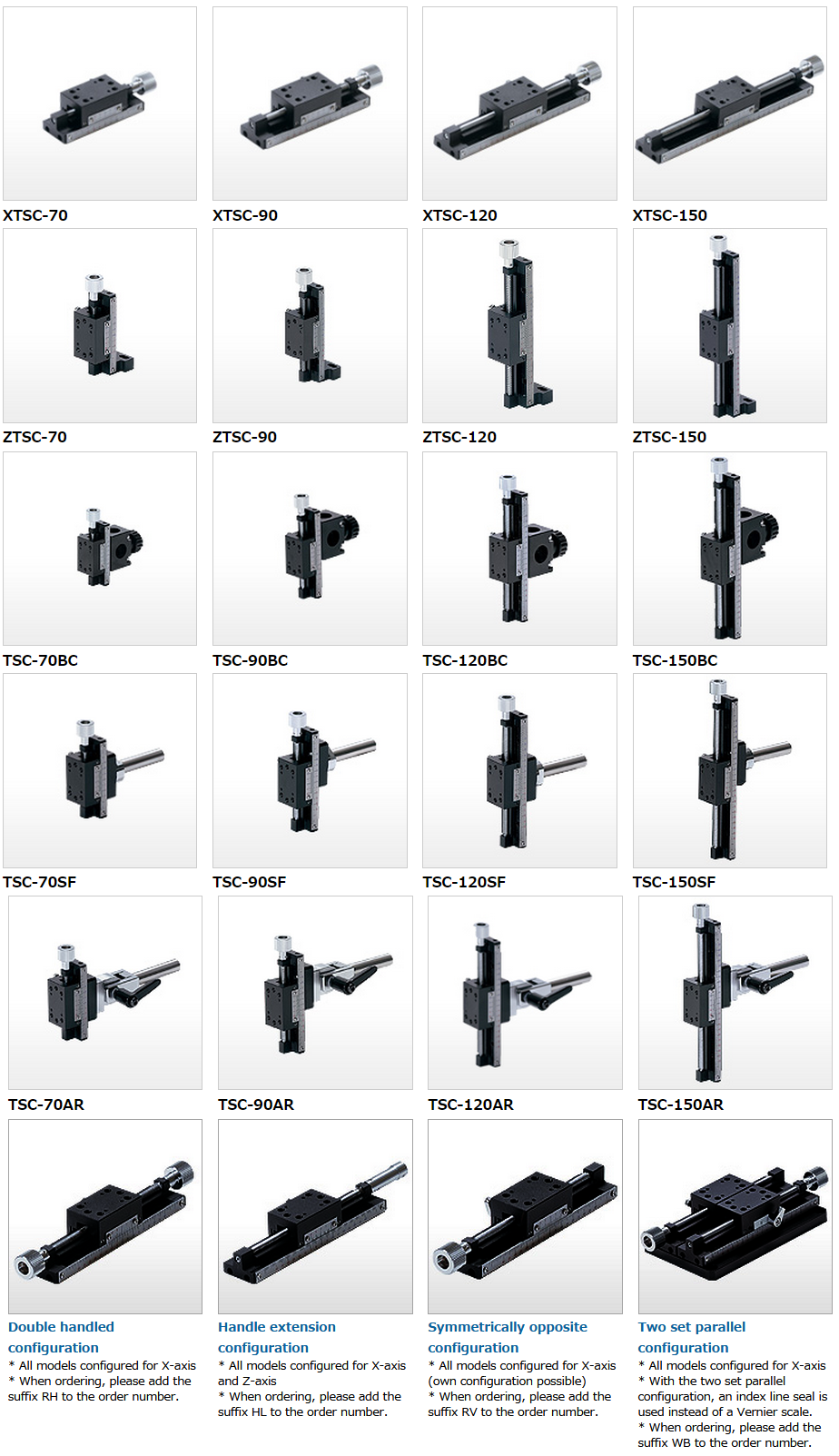

Miruc Dovetail Feed Screw Stage are equipped with scale and revolutionary feed screw lens stage which allows you to select a single rotation of the handle to be set to move by 2 mm, 5 mm or 10 mm. These mechanisms allow extremely small adjustments using commonly available screws. With an easily visible central divider type color scale, the scale and clamp lever can easily be detached and switched from left to right, thus a symmetrically opposite arrangement is simple to make. As optional extras, two handled types, extension handle types and two set parallel types are available. The multi-function feed screw type has a rich array of features, providing long strokes at a regular pitch and with smooth sliding action, extremely useful for application in environments with limited space.

Miruc Dovetail Feed Screw Stage Mechanism:

|

Rotating a bolt through two nuts with slightly different thread pitches for each changes the separation of the nuts by the difference between the threads. |

Overview

Customer values

Each Miruc stages are handcrafted and able to perform fine tuning with milimeter precision. Miruc Dovetail Feed Screw Stage were built to meet your most demanding preference as it is versatile, reliable and requires no lubricant on the maintenance.

Built to last

Since 1963, MIRUC OPTICAL CO.,LTD. have been manufacturing optical peripheral and special equipment to cater both research and industrial needs of visual magnification with measurement capabilities in Japan.

TECHNICAL SPECIFICATION

Miruc Dovetail Feed Screw Stage Ordering Guide:

Miruc Dovetail Stage Screw type

| Model*1 | Stage surface (mm) |

Degree of movement (mm) |

Degree of movement per handle rotation |

Movement precision (μm) |

Load bearing N (kgf) |

Minimum scale reading |

Weight (kg) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| Straightness |

Degree of parallelism during operation |

X-axis | Z-axis | X-axis | Z-axis | |||||

| XTSC-70 ZTSC-70 |

25 x 40 | ± 17 | 2 / 5 | 30 | 30 | 29.4 (3) | 14.7 (1.5) | 0.1 | 0.12 | 0.16 |

| XTSC-90 ZTSC-90 |

25 x 40 | ± 27 | 2 / 5 / 10 | 30 | 30 | 29.4 (3) | 14.7 (1.5) | 0.1 | 0.14 | 0.18 |

| XTSC-120 ZTSC-120 |

25 x 40 | ± 42 | 2 / 5 / 10 | 30 | 30 | 29.4 (3) | 14.7 (1.5) | 0.1 | 0.16 | 0.20 |

| XTSC-150 ZTSC-150 |

25 x 40 | ± 57 | 5 / 10 | 40 | 40 | 29.4 (3) | 14.7 (1.5) | 0.1 | 0.18 | 0.22 |

*1 Depending on the selected degree of travel per handle turn, the model number will end in -2, -5 or -10.

*Where special spec. have been selected, the model number will have the suffix RH, HL, RV, or WB. (E.g., XTSC-90-5RH, ZTSC-150-10HL, etc.)

* Material: stage body: aluminium alloy, surface treatment: matt black alumite

Miruc Dovetail Multi-function feed screw type

| Model *1 | Stage surface (mm) |

Degree of movement (mm) |

Degree of movement per handle rotation |

Movement precision (μm) |

Load bearing N (kgf) |

Minimum scale reading |

Weight (kg) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Straightness |

Degree of parallelism during operation |

X-axis | Z-axis | BC | SF | AR | |||||

| TSC-70BC TSC-70SF TSC-70AR |

25 x 40 | ± 17 | 2 / 5 | 30 | 30 | 29.4 (3) | 14.7 (1.5) | 0.1 | 0.20 | 0.23 | 0.39 |

| TSC-90BC TSC-90SF TSC-90AR |

25 x 40 | ± 27 | 2 / 5 / 10 | 30 | 30 | 29.4 (3) | 14.7 (1.5) | 0.1 | 0.22 | 0.25 | 0.41 |

| TSC-120BC TSC-120SF TSC-120AR |

25 x 40 | ± 42 | 2 / 5 / 10 | 30 | 30 | 29.4 (3) | 14.7 (1.5) | 0.1 | 0.24 | 0.27 | 0.43 |

| TSC-150BC TSC-150SF TSC-150AR |

25 x 40 | ± 57 | 5 / 10 | 40 | 40 | 29.4 (3) | 14.7 (1.5) | 0.1 | 0.26 | 0.29 | 0.45 |

*1 Depending on the selected degree of travel per handle turn, the model number will end in -2, -5 or -10.

* Where special spec. have been selected, the model number will have the suffix RH, HL, or RV. (E.g., TSC-70-BC-2HL, TSC-120-AR-5RH, etc.)

* Material: stage body: aluminium alloy, surface treatment: matt black alumite

|

Notes:

|

Request a Quote

Request A Quote

Please complete the below form to receive further information.