If you want to find out more about

SIC Marking XL-Box Laser system

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

As its name suggests, SIC’s XL-BOX is the flagship among a range of laser workstations, with features and dimensions designed to increase productivity and adapt to the evolving needs of manufacturing and production lines. Modeled after the ever-popular L-BOX, XL-BOX has larger internal dimensions, with a 570 x 564 mm work area that more comfortably accommodates larger-sized components. Constructed of solid steel, it’s a compact 655 mm wide enabling its user to work comfortably when loading/unloading parts to be marked. Much larger than its predecessor, XL-BOX is equipped with a pneumatically-powered, intuitively secure door that automatically locks when the cycle starts and opens when the marking is finished. Operated with the push of a button, it’s a smooth action entry that allows access on all three sides and is equipped with a large viewing window. The “smart” Z-axis operates on a 235 mm (9-1/4”) motorized system; with the additional help of two red focal pointers, focusing a precise mark is simple. XL-BOX is equipped with a high-powered, pulsed wave ytterbium-doped fiber laser which allows shallow or deep markings of alphanumeric codes, barcodes, and 2D Data Matric codes, and on all metals and some plastics. It is easy to operate, even for users with minimal training in laser technology. This versatile laser marking workstation is operated via SIC’s proprietary, user-friendly software: SIC LASER PC. This software – included with the package – can be run using Windows on any PC, and offers multiple configuration options. SIC MARKING LASER TECHNOLOGY Laser marking is recommended for high-volume production, where speed and accuracy are a must. Primarily used for Direct Part Marking (DPM) or Label Marking, the resulting impressions are precise, clear, and readable by the human eye, or verified with vision technology (camera).

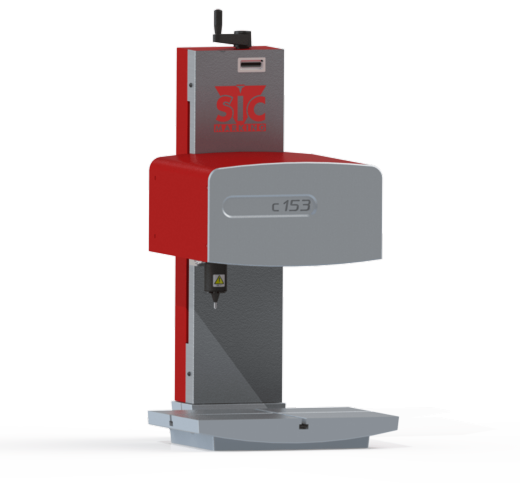

As its name suggests, SIC’s XL-BOX is the flagship among a range of laser workstations, with features and dimensions designed to increase productivity and adapt to the evolving needs of manufacturing and production lines.

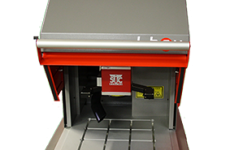

Modeled after the ever-popular L-BOX, XL-BOX has larger internal dimensions, with a 570 x 564 mm work area that more comfortably accommodates larger-sized components. Constructed of solid steel, it’s a compact 655 mm wide enabling its user to work comfortably when loading/unloading parts to be marked.

Much larger than its predecessor, XL-BOX is equipped with a pneumatically-powered, intuitively secure door that automatically locks when the cycle starts and opens when the marking is finished. Operated with the push of a button, it’s a smooth action entry that allows access on all three sides and is equipped with a large viewing window. The “smart” Z-axis operates on a 235 mm (9-1/4”) motorized system; with the additional help of two red focal pointers, focusing a precise mark is simple.

XL-BOX is equipped with a high-powered, pulsed wave ytterbium-doped fiber laser which allows shallow or deep markings of alphanumeric codes, barcodes, and 2D Data Matric codes, and on all metals and some plastics. It is easy to operate, even for users with minimal training in laser technology.

This versatile laser marking workstation is operated via SIC’s proprietary, user-friendly software: SIC LASER PC. This software – included with the package – can be run using Windows on any PC, and offers multiple configuration options.

SIC MARKING LASER TECHNOLOGY

Laser marking is recommended for high-volume production, where speed and accuracy are a must. Primarily used for Direct Part Marking (DPM) or Label Marking, the resulting impressions are precise, clear, and readable by the human eye, or verified with vision technology (camera).

Overview

TECHNICAL SPECIFICATION

MECHANIC FEATURES

|

Marking Window: |

170 x 170 mm or 100 x 100 mm |

|

External Dimensions (l x d x h): |

655 x 756 x 1020 mm |

|

Working Area: |

570 x 564 mm |

|

Marked Part Maximum Height & Length: |

370 mm, 570 mm |

|

Security: |

Class 1 Configuration |

|

Control: |

PC-Based Operation |

ELECTRONIC FEATURES

The XL-Box fiber laser is column mounted marking system designed to operate with the Rack-Controller Fiber Unit.

|

Source: |

Pulsed Ytterbium Fiber Laser |

|

Operation Mode: |

Pulsed (20 to 500 kHz) |

|

Wavelength: |

1064 nm |

|

Optical fiber length: |

3m |

|

Average power: |

10,20W, or 50W |

|

Peak power: |

10kw |

|

Positionning/Focus: |

Built-in Laser Pointer |

|

Cooling: |

Air-Cooled Only |

STEERING SOFTWARE

The XL-BOX marking machine operates using SIC Laser PC, a proprietary software that will run on any PC with a Windows operating system. Marking files can be created and edited directly through the software, and a multitude of configuration options allow complete customization of the mark itself. Improve the contrast and optimize the cycle time by changing the speed, frequency, and power.

SIC Laser PC is user-friendly and requires minimal training to operate efficiently:

- Create and edit marking files (drawing, text, barcode, data matrix...)

- Several pen settings (speed, power, frequency...)

- Font Options: true type, 1D barcode, 2D data matrix

- Import Pictures (.bmp, .jpg) and Vectorial Files (.plt, .dxf, .ai)

- Database Function: link with external files (.txt, .xls)

- Marking of Cylindrical parts

- Intergrated Inpout/Output

Request a Quote

Request A Quote

Please complete the below form to receive further information.