If you want to find out more about

Sisma Laser Welding SWA 300F/450F

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

SWA has been specially designed to perform modifications and repairs to molds damaged by wear or use. The use of lasers, with the addition of materials, has revolutionized the traditional welding techniques of molds, allowing repairs without the need for preheating. This avoids the common collateral damage induced by traditional weldings, such as geometric distortions, edge burns, and decarburization. Thanks to the properties of the laser beam, complex areas such as narrow and deep grooves, or internal and external edges, can be welded. The metallurgical quality of the weld meets the highest standards on all steels, copper alloys, and aluminum. The hardness of the welding layers can reach very high values without the need for subsequent heat treatments. Its simple way of operating and perfect visual inspection of the filler material, using a stereomicroscope, make this technology accessible to everyone, without having to rely on highly qualified technicians. SWA is powered by a new-generation laser source that offers greater energy efficiency and allows for high productivity. ProductivityThe new SWA introduces more process stability and a high-quality laser beam. These features increase the production rate, while consistently guaranteeing flawless process execution. Maintenance-freeThe new SWA does not have any consumable parts and is maintenance-free. The engineering team has pushed the boundaries of energy efficiency, making this the most efficient SWA ever made. Advanced software functionsThe processing parameters are managed through software that allows any operator to carry out advanced welding operations practically and intuitively. These software functions include welding along circular paths, on inclined planes, filling, and the overlap function for executing extremely regular weld seams. SWA has been specifically designed to perform modifications, maintenance, and repairs on molds damaged by wear or use: it is powered by a new-generation laser source that offers greater energy efficiency and allows for high productivity. Multifunction console Operator presence verification Axes movement and laser parameters control Ergonomic and easily placeable near the working area Read more about this machine in our blog. LFC is the authorized distributor for Sisma in Singapore and Indonesia. Contact us if you wish to discuss this machine further.

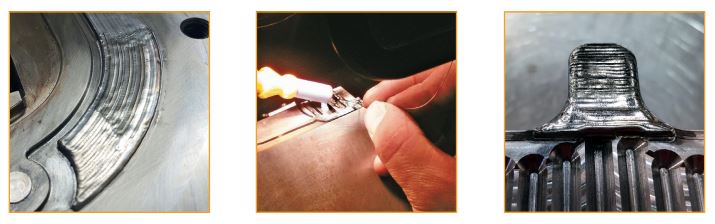

SWA has been specially designed to perform modifications and repairs to molds damaged by wear or use.

The use of lasers, with the addition of materials, has revolutionized the traditional welding techniques of molds, allowing repairs without the need for preheating. This avoids the common collateral damage induced by traditional weldings, such as geometric distortions, edge burns, and decarburization.

Thanks to the properties of the laser beam, complex areas such as narrow and deep grooves, or internal and external edges, can be welded. The metallurgical quality of the weld meets the highest standards on all steels, copper alloys, and aluminum. The hardness of the welding layers can reach very high values without the need for subsequent heat treatments. Its simple way of operating and perfect visual inspection of the filler material, using a stereomicroscope, make this technology accessible to everyone, without having to rely on highly qualified technicians.

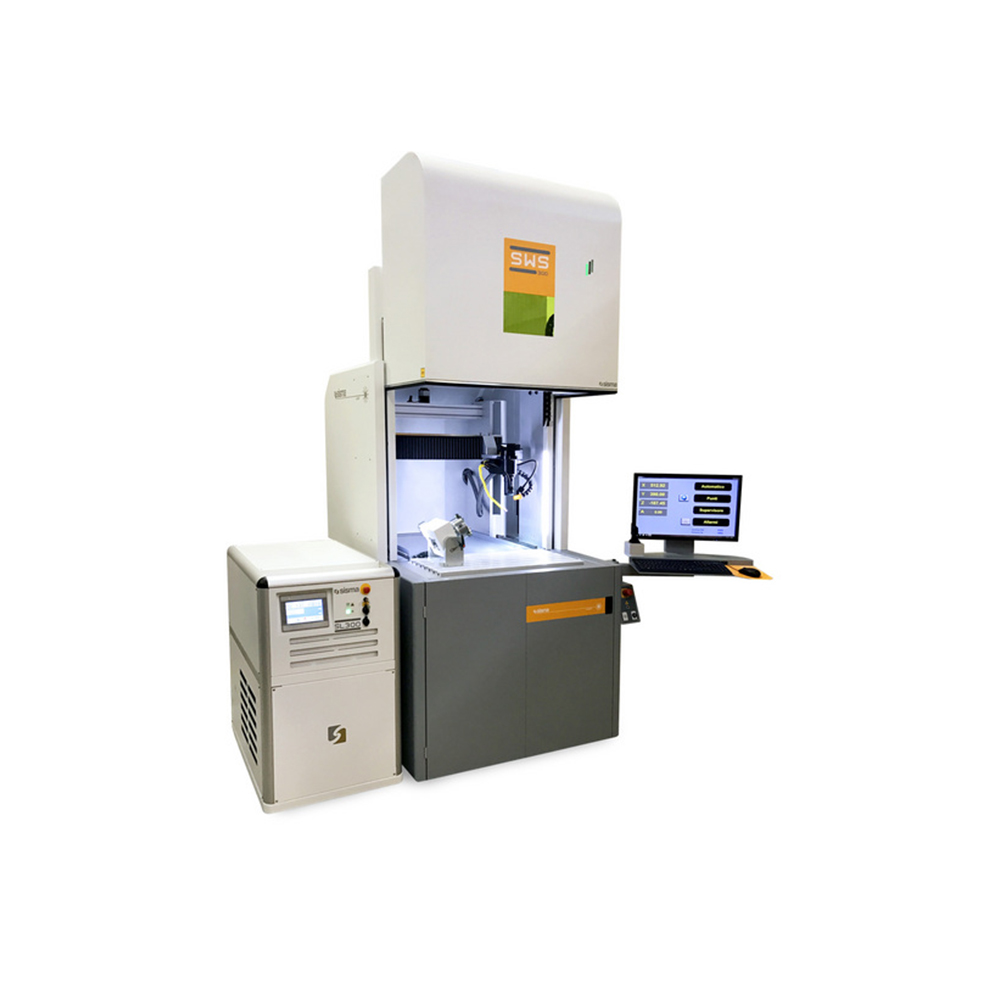

SWA is powered by a new-generation laser source that offers greater energy efficiency and allows for high productivity.

Productivity

The new SWA introduces more process stability and a high-quality laser beam. These features increase the production rate, while consistently guaranteeing flawless process execution.

Maintenance-free

The new SWA does not have any consumable parts and is maintenance-free. The engineering team has pushed the boundaries of energy efficiency, making this the most efficient SWA ever made.

Advanced software functions

The processing parameters are managed through software that allows any operator to carry out advanced welding operations practically and intuitively. These software functions include welding along circular paths, on inclined planes, filling, and the overlap function for executing extremely regular weld seams.

SWA has been specifically designed to perform modifications, maintenance, and repairs on molds damaged by wear or use: it is powered by a new-generation laser source that offers greater energy efficiency and allows for high productivity.

Multifunction console

- Operator presence verification

- Axes movement and laser parameters control

- Ergonomic and easily placeable near the working area

Read more about this machine in our blog. LFC is the authorized distributor for Sisma in Singapore and Indonesia. Contact us if you wish to discuss this machine further.

Overview

TECHNICAL SPECIFICATION

Sisma Laser Welding SWA 300F / SWA 450F Specifications

| Technical Data | SWA 300F | SWA 450F |

| Source type | Fiber | Fiber |

| Wavelength | 1070 nm | 1070 nm |

| Average power | 300 W | 450W |

| Max peak power | 3 kW | 4.5 kW |

| Max pulse energy | 30 J | 45 J |

| Pulse duration | 0.1 ÷ 10 ms / CW | 0.1 ÷ 10 ms / CW |

| Shot frequency | 0 ÷ 50 Hz | 0 ÷ 50 Hz |

| Spot diameter | 0.1 ÷ 2 mm | 0.1 ÷ 2 mm |

| Integrated cooling | Air | Air |

| X axis stroke | 300 mm | 300 mm |

| Y axis stroke | 150 mm | 150 mm |

| Z axis stroke | 500 mm | 500 mm |

| Axes speed | 0.1 ÷ 30 mm/s | 0.1 ÷ 30 mm/s |

| Power supply | 230 V 1ph - 2 kW | 230 V 1ph - 2.6 kW |

| Dimensions (W x D x H) | 1260 mm (without junction) - 1410 mm (with junction) x 1980 mm x 1650 mm | |

| Weight (without junction) | 320 kg | 325 kg |

Request a Quote

Request A Quote

Please complete the below form to receive further information.