If you want to find out more about

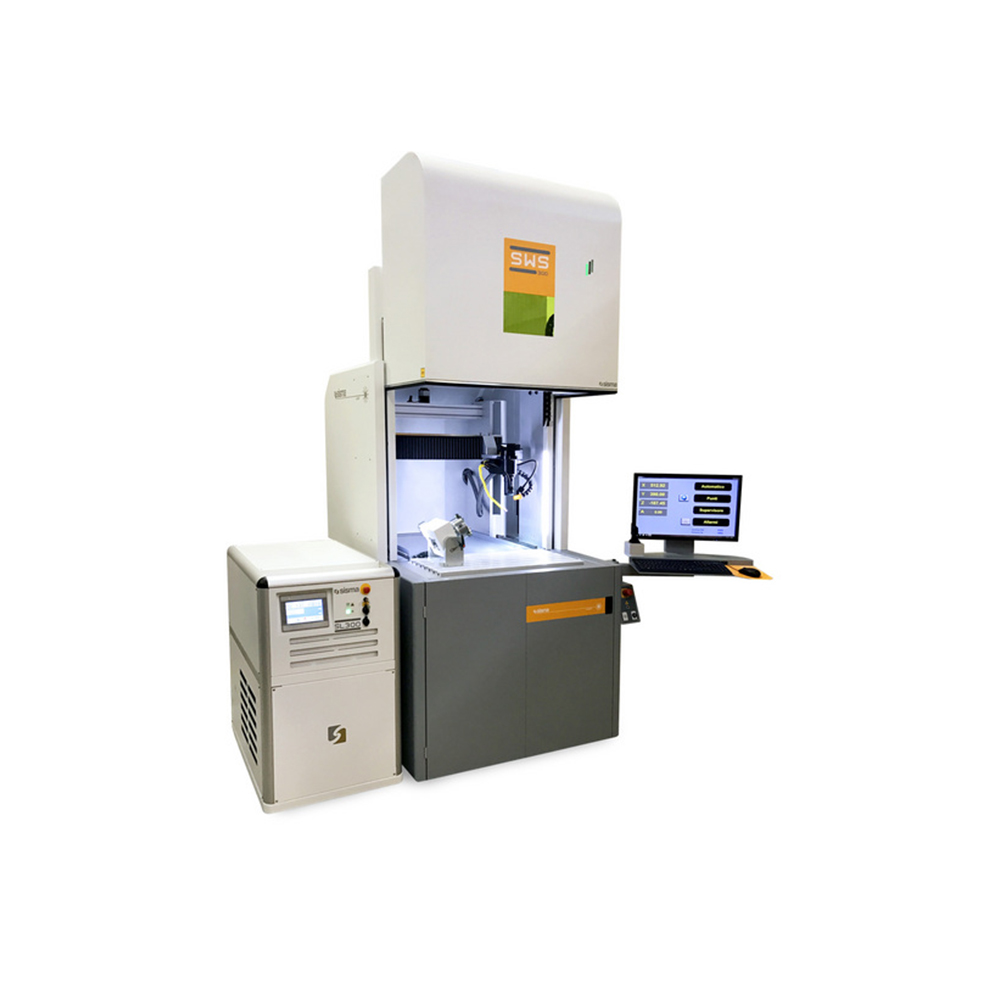

Sisma Laser Welding Station SWS Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

The Sisma Laser Welding SWS series has been engineered for the maintenance of a high volume of small/medium-sized molds and die repair with a high level of precision. The efficient laser welding machine is offered with an enclosed vertical lid which is intended for welding and mold maintenance with and without filler material. You can easily set up adjustments height of the optic head on motorized function. The 3/4 axes CNC welding station feature the axis motion system that ensures high accuracy thanks to the solidity of the structure and the materials used. The laser source has been optimized for high operating stability at both low and high power, while the fully integrated radiator cooling system makes SWS suitable for both small infill operations and extended use. It is equipped with a 21" screen PC, and intuitive Sisma software for more straightforward configuration to manage laser parameters, the control of the waveform, the diameter of welding, and spindle rotation as well. Sisma SWS welding laser works by utilizing a Fiber Ytterbium (Yag) laser beam which emits light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser). Your investment in Sisma's laser welding technology will allow you to produce the world's highest accuracy which comes without the need for regular head source maintenance, optical replacement, mixed gas (argon & C02), Co2 nozzle consumables, pressure gauges, and excessive fire retardant kit which must be maintained and replaced meticulously. Sisma's Laser Source in terms of power and stability is offered with 4 models based on power wattage (25 - 1000). However, if you are looking for a more versatile machine with a rotatable laser head and joystick operation, you might also want to consider the Sisma Laser Welding SWA series. Sisma Laser Welding Station SWS Features: Designed for high-powered daily routines for precision plastic injection mold repair, stamping dies, precision heavy press brake dies, engraving, and finishing on tough metals. Advanced software functions such as welding on the circumference, line, filling, and rotating spindle management High laser beam quality: new optical design ensures high performance Sturdy working enclosure with table to allow the operator to work comfortably and without vibrations. Available with fiber laser source: maintenance-free and low power consumption Internet connection for remote control is also possible Radiator cooling system with electronic control board located separately at its container to avoid excessive heat and magnetic-electrical impedance. Designed for extended use or small-facing operations, this is the ideal tool for keeping your molds in top working condition. Can also be ordered with a magnetic vise, cooling panel, and other accessories to support you in working with shifts and busy queues. Argon gas is only used to avoid oxidation as a shielding gas on welding joints.

The Sisma Laser Welding SWS series has been engineered for the maintenance of a high volume of small/medium-sized molds and die repair with a high level of precision. The efficient laser welding machine is offered with an enclosed vertical lid which is intended for welding and mold maintenance with and without filler material. You can easily set up adjustments height of the optic head on motorized function. The 3/4 axes CNC welding station feature the axis motion system that ensures high accuracy thanks to the solidity of the structure and the materials used.

The laser source has been optimized for high operating stability at both low and high power, while the fully integrated radiator cooling system makes SWS suitable for both small infill operations and extended use. It is equipped with a 21" screen PC, and intuitive Sisma software for more straightforward configuration to manage laser parameters, the control of the waveform, the diameter of welding, and spindle rotation as well. Sisma SWS welding laser works by utilizing a Fiber Ytterbium (Yag) laser beam which emits light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser).

Your investment in Sisma's laser welding technology will allow you to produce the world's highest accuracy which comes without the need for regular head source maintenance, optical replacement, mixed gas (argon & C02), Co2 nozzle consumables, pressure gauges, and excessive fire retardant kit which must be maintained and replaced meticulously. Sisma's Laser Source in terms of power and stability is offered with 4 models based on power wattage (25 - 1000). However, if you are looking for a more versatile machine with a rotatable laser head and joystick operation, you might also want to consider the Sisma Laser Welding SWA series.

Sisma Laser Welding Station SWS Features:

- Designed for high-powered daily routines for precision plastic injection mold repair, stamping dies, precision heavy press brake dies, engraving, and finishing on tough metals.

- Advanced software functions such as welding on the circumference, line, filling, and rotating spindle management

- High laser beam quality: new optical design ensures high performance

- Sturdy working enclosure with table to allow the operator to work comfortably and without vibrations.

- Available with fiber laser source: maintenance-free and low power consumption

- Internet connection for remote control is also possible

- Radiator cooling system with electronic control board located separately at its container to avoid excessive heat and magnetic-electrical impedance.

- Designed for extended use or small-facing operations, this is the ideal tool for keeping your molds in top working condition.

- Can also be ordered with a magnetic vise, cooling panel, and other accessories to support you in working with shifts and busy queues.

- Argon gas is only used to avoid oxidation as a shielding gas on welding joints.

Overview

Built to last

Customer values

TECHNICAL SPECIFICATION

Sisma SWS Mould & Dies Welding Laser Station Ordering Guide:

| Technical Data | SWS | SWS | SWS | SWS |

| 25 - 80 | 150 - 300 | 150F - 450F | 1000F | |

| Source type | Nd:YAG (flash lamp) | Nd:YAG (flash lamp) | Fiber laser | Fiber laser |

| Wavelength | 1064 nm | 1064 nm | 1070 nm | 1070 nm |

| Average laser power | 25 - 80 W | 150 - 300 W | Up to 450 W | 1000 W |

| Max peak power | Up to 7,5 kW | 10,5 - 12 kW | Up to 4,5 kW | 1000 W |

| Max pulse energy | Up to 70 J | 75 J - 150 J | Up to 45 J | - |

| Pulse duration | 0,2 ms - 20 ms | 0,2 ms - 25 ms | 0,2 ms - 10 ms CW | CW |

| X axis stroke | 520 mm | 520 mm | 520 mm | 520 mm |

| Y axis stroke | 400 mm | 400 mm | 400 mm | 400 mm |

| Z axis stroke | 400 mm | 400 mm | 400 mm | 400 mm |

| Axes precision | ± 60 µm | ± 60 µm | ± 60 µm | ± 60 µm |

| Axes repeatability | ± 30 µm | ± 30 µm | ± 30 µm | ± 30 µm |

| Dimensions (laser source excluded) | 120 x 135 x h 200 cm | 120 x 135 x h 200 cm | 120 x 135 x h 200 cm | 120 x 135 x h 200 cm |

| Weight (laser source excluded) | 450 kg | 450 kg | 450 kg | 450 kg |

| Power supply | 1ph 230 V ± 10% | 3ph 380 V ± 10% | 1ph 230 V ± 10% | 1ph 230 V ± 10% |

| 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz |

Request a Quote

Request A Quote

Please complete the below form to receive further information.