- Home

- Products

- Cutting Tools

- Shoulder Mill

- WIDIA M690 Series for 90° Shoulder Mills

If you want to find out more about

WIDIA M690 Series for 90° Shoulder Mills

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

WIDIA™ M690 Series for 90° Shoulder Mills are devised to increase your manufacturing flexibility and reduce tooling cost. Widia's M690 Series for 90° Shoulder Mills™ are quipped with insert which works faster and precise under lower temperature thus improve tool life, precise, thus enables time saving, economic and practicality. WIDIA M690 Series for 90° Shoulder Mills are available in grades for high-speed applications, high toughness demands, and high metal-removal rates. Specific geometries are also available with such features as reinforced cutting edges and a steep chipbreaker for steel, cast iron, and short-chipping materials, or an optimized chip groove for stainless steel, long-chipping steels, and where low power consumption is required. Types of body available for WIDIA™ shoulder mills M690 Series : 1. WIDIA™ Shell Mills SD1204, which features: Four cutting edges for precision cutting. 90° shoulders with coated carbide allows spartan performance. Excellent for slot and profile milling. Standard milling cutters will accept insert nose radius up to 2mm without modification. Common insert replacement part. PDF catalog on metric can be downloaded here and on inches here 2. WIDIA™ Shell Mills SD1506, which features: Four cutting edges. 90° shoulders. Excellent for slot and profile milling. Designed to withstand operation at higher temperature as operated with trough coolant. Common insert replacement parts. PDF catalog on metric can be downloaded here and on inches here

WIDIA™ M690 Series for 90° Shoulder Mills are devised to increase your manufacturing flexibility and reduce tooling cost. Widia's M690 Series for 90° Shoulder Mills™ are quipped with insert which works faster and precise under lower temperature thus improve tool life, precise, thus enables time saving, economic and practicality.

WIDIA M690 Series for 90° Shoulder Mills are available in grades for high-speed applications, high toughness demands, and high metal-removal rates. Specific geometries are also available with such features as reinforced cutting edges and a steep chipbreaker for steel, cast iron, and short-chipping materials, or an optimized chip groove for stainless steel, long-chipping steels, and where low power consumption is required.

Types of body available for WIDIA™ shoulder mills M690 Series :

1. WIDIA™ Shell Mills SD1204, which features:

- Four cutting edges for precision cutting.

- 90° shoulders with coated carbide allows spartan performance.

- Excellent for slot and profile milling.

- Standard milling cutters will accept insert nose radius up to 2mm without modification.

- Common insert replacement part.

- PDF catalog on metric can be downloaded here and on inches here

2. WIDIA™ Shell Mills SD1506, which features:

- Four cutting edges.

- 90° shoulders.

- Excellent for slot and profile milling.

- Designed to withstand operation at higher temperature as operated with trough coolant.

- Common insert replacement parts.

- PDF catalog on metric can be downloaded here and on inches here

Overview

Customer values

Widia master the coating technology from TICN coating, CBN (Superhard cubic boron nittride /cBN) for Cast Iron / Sintered Metals, and PCD (diamond) tip for highly abrasive material. With thousands of milling, turning, holemaking, and tooling systems products available you´ll find everything you need from one single source.

Built to perform

Since 1929, WIDIA holds the world’s first patent for coating indexable inserts, taps and mills with Tungsten carbide application on cutting-tools. Widia cutting tools are recorded adheres to every DIN, ISO standard and several JIS standard for easier conversion and replacement.

Customer values

TECHNICAL SPECIFICATION

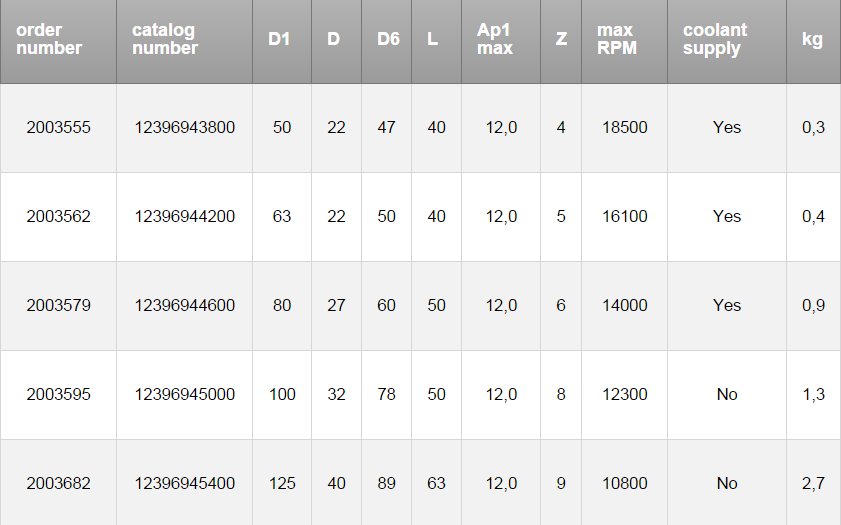

WIDIA™ Shoulder Mills M690 Serie 1506

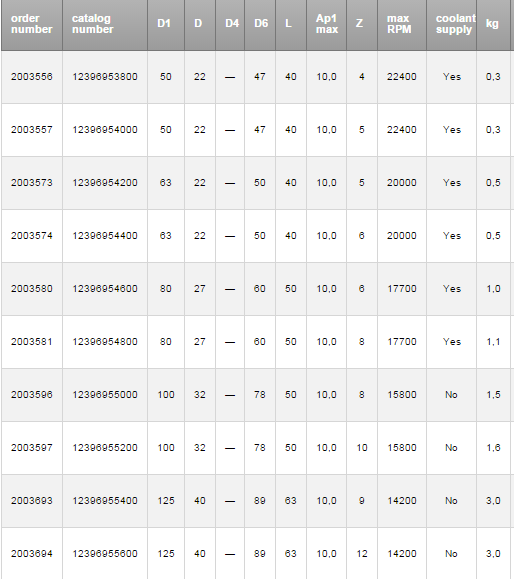

WIDIA™ Shoulder Mills M690 1204 serie

WIDIA™ manufactures bar peeling toolholders, tool heads, inserts, and accessories for all your bar peeling needs.

Request a Quote

Request A Quote

Please complete the below form to receive further information.