- Home

- Products

- Bandsaw Machines

- Straight-Cutting

- MEP Shark 660 CNC HS 4.0 Automatic Bandsaw

If you want to find out more about

MEP Shark 660 CNC HS 4.0 Automatic Bandsaw

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

MEP Shark 660 CNC HS 4.0 Automatic Bandsaw Shark 660 CNC HS 4.0, dual-column electromechanical automatic band sawing machine for 0° cuts of structural, stainless, and alloy steels, solids, and profiles. In addition to the automatic cutting cycle, it can also operate in semi-automatic mode. Absolute Efficiency The two working modes (semi-automatic and automatic) allow for performing any kind of cut in the most efficient way. The control allows to storage of up to 300 cutting programs, each one with different quantities and lengths, minimizing the programming time of regular jobs. The automatic acquisition of the saw head-cutting start position reduces programming time. The automatic alignment of the front blade guide head according to the dimensions of the bars to cut reduces setting time. The blade tensioning through the brushless motor is constantly checked and adjusted in real-time, thus granting a higher cutting precision and longer blade life. The blade deviation control device allows performing cuts always in perfect tolerance. The cutting vice with a fixed hydraulic retractable back jaw makes feeding of non-straight bars or bundles held with stripes smoother. Here are some features of MEP Shark 660 CNC HS 4.0 Automatic Bandsaw, including: Adaptative Saw Head Down Feed Rate Self-regulation in real-time of head-down feed rate according to a type of material or blade wear. Material Library for The Automatic Setting of The Blade Rotation Speed and Head Down Feed Rate The material library allows the automatic setting of the blade speed (S) and head-down feed rate (F) according to the type of material. Floating Bar Feeder Vice The bar feeder vice is self-aligning in order to feed even non-straight bars. Motion Of The Saw Head On Linear Guides The motion of the saw head powered by a pneumatic cylinder for an auto-check of all data set/recorded so as to adjust cutting parameters in real-time, counterbalancing through a hydraulic cylinder to give the machine cutting stability, and Ø 32mm ball bearings screw nut to ensure a mechanical vibration reduction during the cut.

MEP Shark 660 CNC HS 4.0 Automatic Bandsaw

Shark 660 CNC HS 4.0, dual-column electromechanical automatic band sawing machine for 0° cuts of structural, stainless, and alloy steels, solids, and profiles. In addition to the automatic cutting cycle, it can also operate in semi-automatic mode.

Absolute Efficiency

- The two working modes (semi-automatic and automatic) allow for performing any kind of cut in the most efficient way.

- The control allows to storage of up to 300 cutting programs, each one with different quantities and lengths, minimizing the programming time of regular jobs.

- The automatic acquisition of the saw head-cutting start position reduces programming time.

- The automatic alignment of the front blade guide head according to the dimensions of the bars to cut reduces setting time.

- The blade tensioning through the brushless motor is constantly checked and adjusted in real-time, thus granting a higher cutting precision and longer blade life.

- The blade deviation control device allows performing cuts always in perfect tolerance.

- The cutting vice with a fixed hydraulic retractable back jaw makes feeding of non-straight bars or bundles held with stripes smoother.

Here are some features of MEP Shark 660 CNC HS 4.0 Automatic Bandsaw, including:

|

Adaptative Saw Head Down Feed Rate Self-regulation in real-time of head-down feed rate according to a type of material or blade wear. |

|

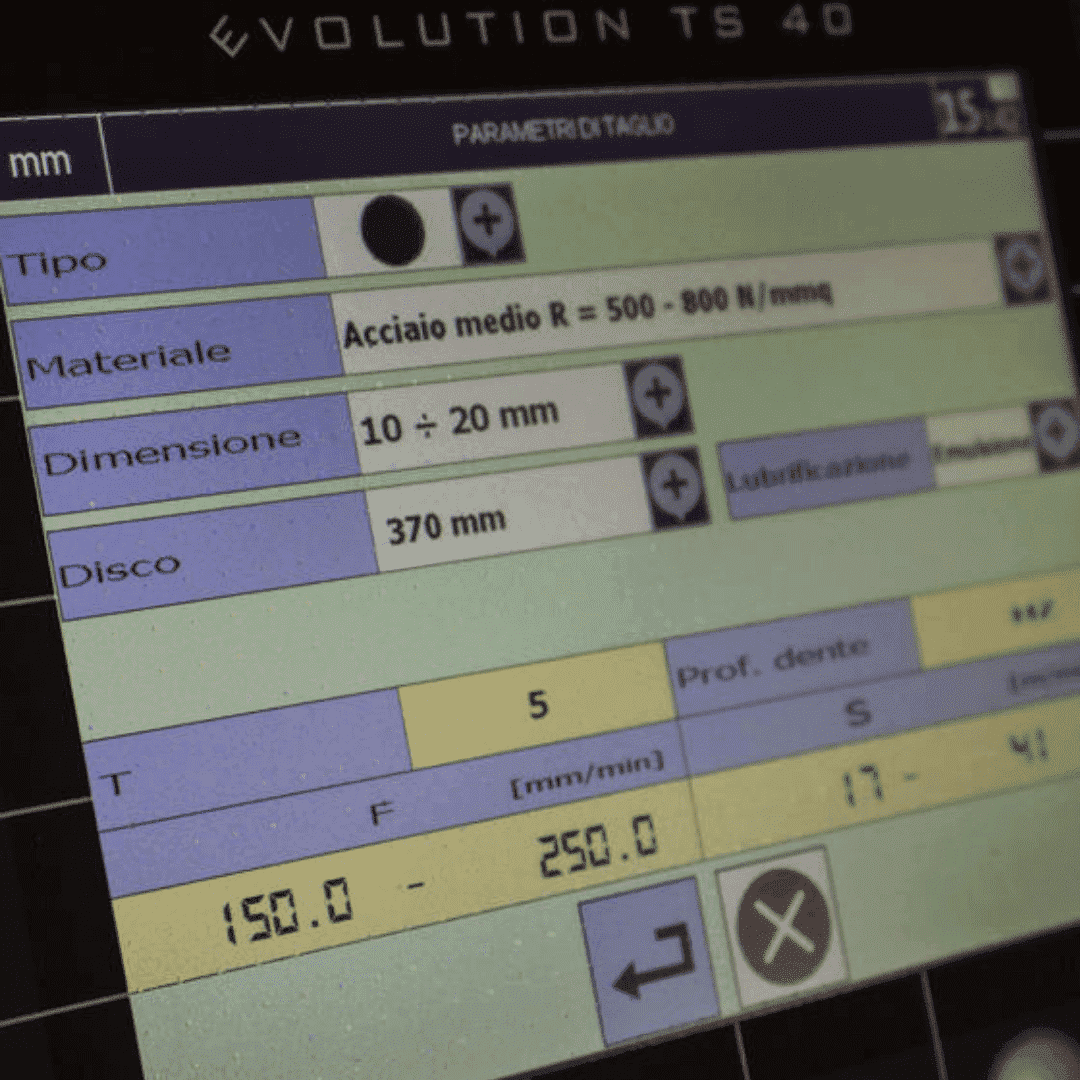

Material Library for The Automatic Setting of The Blade Rotation Speed and Head Down Feed Rate The material library allows the automatic setting of the blade speed (S) and head-down feed rate (F) according to the type of material. |

|

|

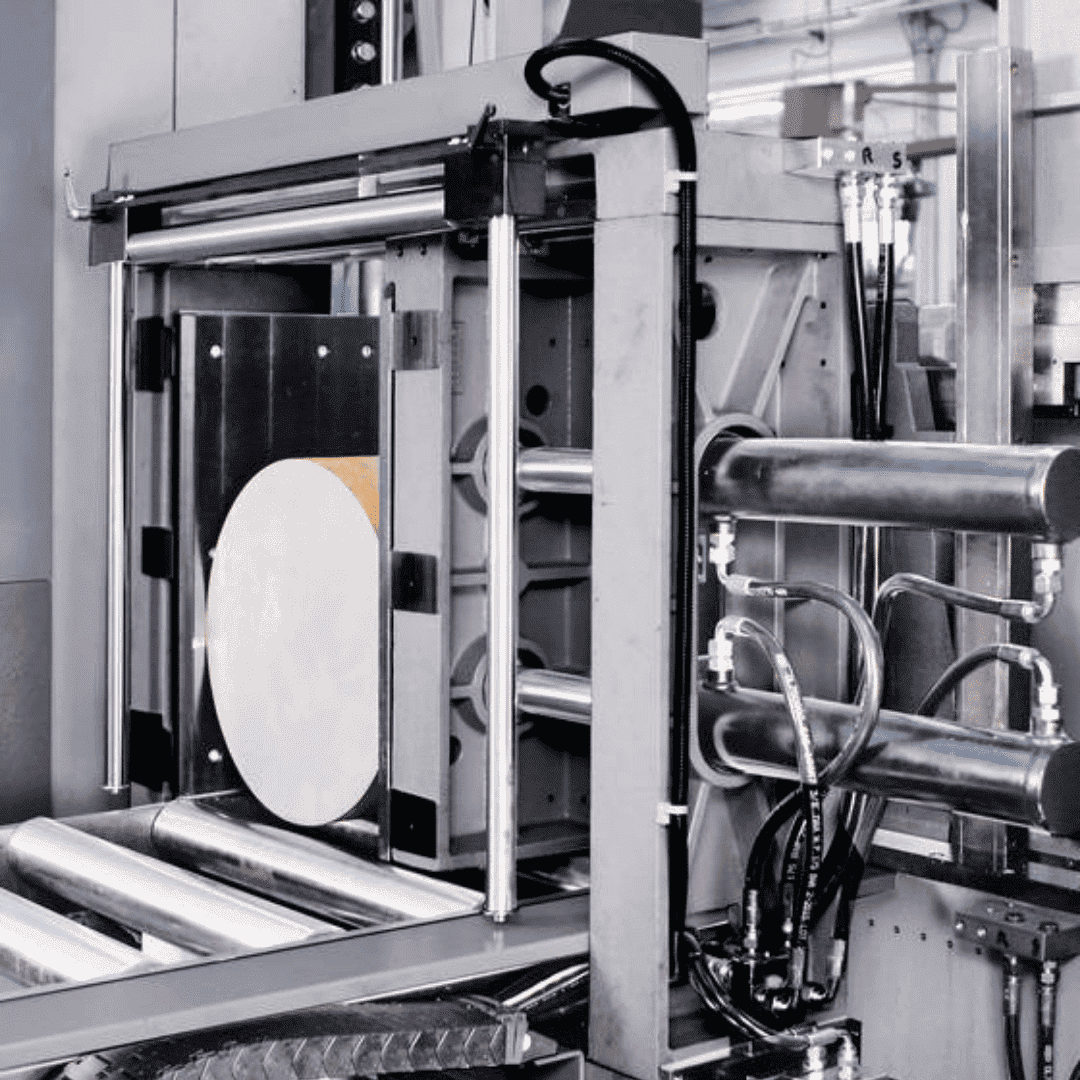

Floating Bar Feeder Vice The bar feeder vice is self-aligning in order to feed even non-straight bars. |

|

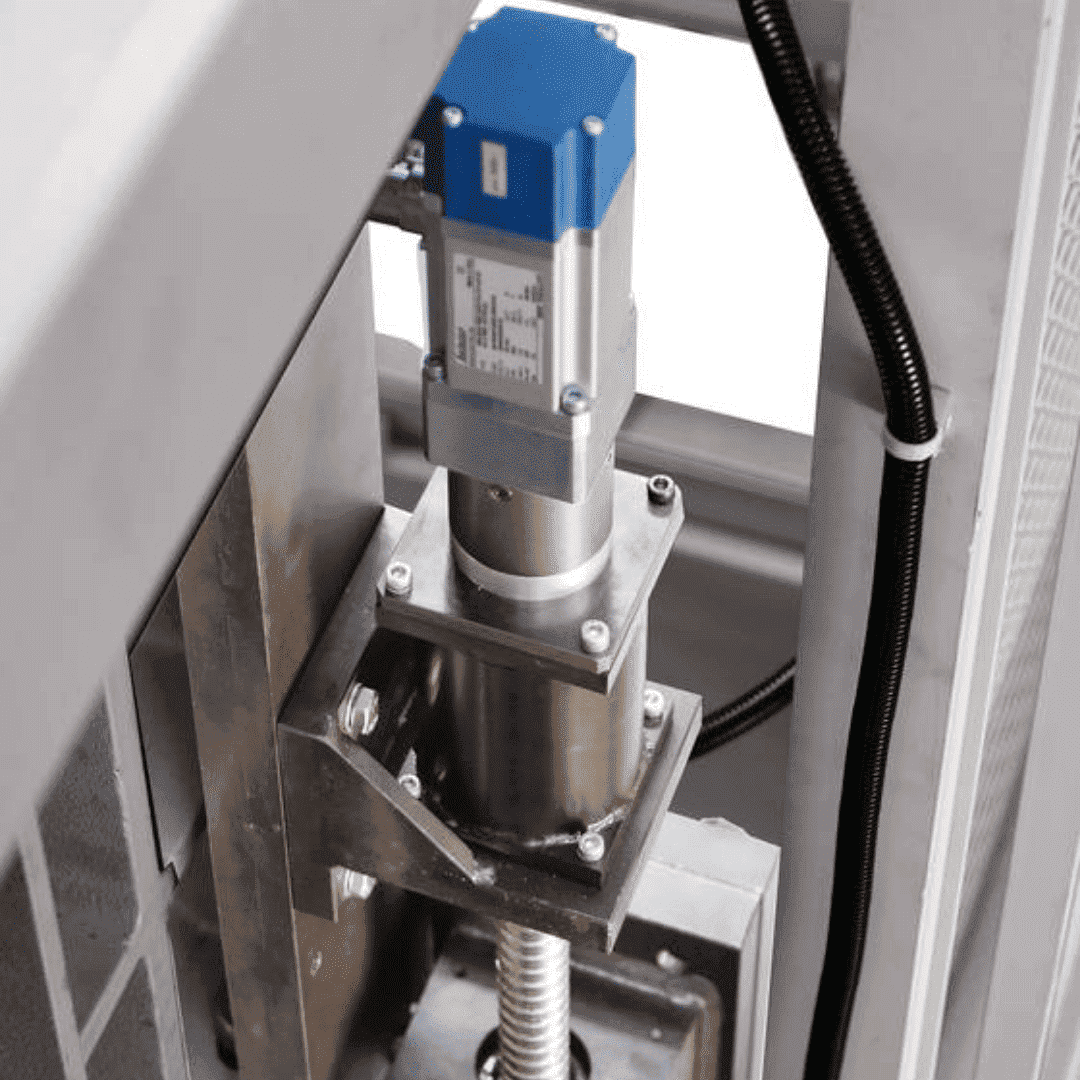

Motion Of The Saw Head On Linear Guides The motion of the saw head powered by a pneumatic cylinder for an auto-check of all data set/recorded so as to adjust cutting parameters in real-time, counterbalancing through a hydraulic cylinder to give the machine cutting stability, and Ø 32mm ball bearings screw nut to ensure a mechanical vibration reduction during the cut. |

|

Overview

TECHNICAL SPECIFICATION

|

|

|

| 0° | 660 mm | 660 mm |

| Max. vice opening | 670 mm |

| Band size | 8400 x 54 x 1.6 mm |

| Blade motor power | 15 kw - Three-phase |

| Blade rotation speed | 15 ÷ 200 m/min |

| Capacity of coolant tank | 340 L |

| Height of working table | 890 mm |

Request a Quote

Request A Quote

Please complete the below form to receive further information.