- Home

- Products

- Circular Saw Machines

- Behringer Eisele Automatic Circular Saw Machine VA-L Series

If you want to find out more about

Behringer Eisele Automatic Circular Saw Machine VA-L Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

VA-L 350 and VA-L 560. Short processes in sawing operation Key features of the series are the robust design, state-of-the-art drive technology used in the feed axis and main drive system, and the extreme rigidity of the ultra-precise saw spindle bearing. The result: an optimized, low-vibration cutting process providing extreme cutting output, excellent surface quality and maximum availability. Pneumatic or hydraulic clamping You have the choice between a pneumatic clamping fixture for gentle clamping and a hydraulic alternative for greater power when processing predominantly solid material. For parallel cuts, both systems are able to cope easily even where a slight torsion exists in the material. Two feeding systems The frequency-controlled main drive system offers scope for adjusting the cutting speed to the sawing process so that both high-strength Al-Si alloys and thin-walled pipes and profiles can be sawn. Two saw feed systems are available: Hydraulic as standard and servo motor-controlled feed as a high-performance option. Features 1. Intuitive Control System The touchscreen control is designed to be easily learned and understood, as well as convenient and simple to operate. A job memory allows recurring profile data to be stored, saving time and guaranteeing quick and accurate reproduction of results. Profile and order data can be imported directly from the customer’s network via the control system’s Ethernet port. 2. Material feed system with controlled zero edge The NC axis with ball screw and servo drive in conjunction with a controlled zero edge guarantees extreme positioning accuracy. The controlled zero edge helps ensure gentle material handling. 3. Extreme ease of access An invaluable bonus when it comes to servicing and repairs: The casing can be opened up to expose large areas of the machine. All the important components and parts are easily accessible. The machine’s open design affords direct access to all important components, facilitating maintenance, cleaning, repairs and saw blade exchange. 4. Automatic widening of kerf channel The kerf extension allows clear return travel of the saw blade by pressing back the material and the offcut on both sides. The effect: increased service life of tools and elimination of scratching on the cut surface during blade retraction.

VA-L 350 and VA-L 560. Short processes in sawing operation

Key features of the series are the robust design, state-of-the-art drive technology used in the feed axis and main drive system, and the extreme rigidity of the ultra-precise saw spindle bearing. The result: an optimized, low-vibration cutting process providing extreme cutting output, excellent surface quality and maximum availability.

Pneumatic or hydraulic clamping

You have the choice between a pneumatic clamping fixture for gentle clamping and a hydraulic alternative for greater power when processing predominantly solid material. For parallel cuts, both systems are able to cope easily even where a slight torsion exists in the material.

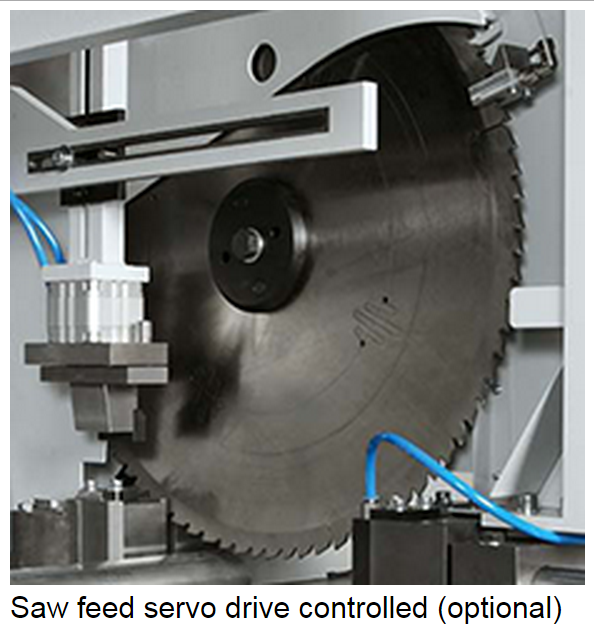

Two feeding systems

The frequency-controlled main drive system offers scope for adjusting the cutting speed to the sawing process so that both high-strength Al-Si alloys and thin-walled pipes and profiles can be sawn. Two saw feed systems are available: Hydraulic as standard and servo motor-controlled feed as a high-performance option.

Features

1. Intuitive Control System

The touchscreen control is designed to be easily learned and understood, as well as convenient and simple to operate. A job memory allows recurring profile data to be stored, saving time and guaranteeing quick and accurate reproduction of results. Profile and order data can be imported directly from the customer’s network via the control system’s Ethernet port.

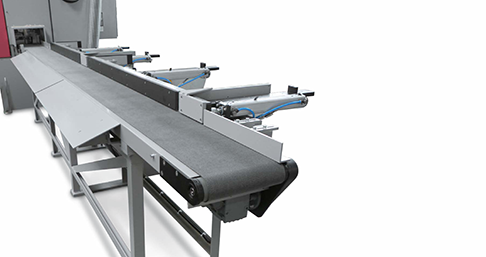

2. Material feed system with controlled zero edge

The NC axis with ball screw and servo drive in conjunction with a controlled zero edge guarantees extreme positioning accuracy. The controlled zero edge helps ensure gentle material handling.

3. Extreme ease of access

An invaluable bonus when it comes to servicing and repairs: The casing can be opened up to expose large areas of the machine. All the important components and parts are easily accessible. The machine’s open design affords direct access to all important components, facilitating maintenance, cleaning, repairs and saw blade exchange.

4. Automatic widening of kerf channel

The kerf extension allows clear return travel of the saw blade by pressing back the material and the offcut on both sides. The effect: increased service life of tools and elimination of scratching on the cut surface during blade retraction.

Overview

Customer values

Behringer machinery are rigid, torsionally-resistant and low-vibration sawing frames in a stable cast design and backlash-free pre-tensioned quadruple guides for precision sawing results. Behringer band saw is covered with five (5) year of limited warranty.

Built to last

BEHRINGER GmbH was founded in Germany 1919. after taking over circular sawing specialist EISELE in the year 2000, BEHRINGER GmbH has been one of the few complete suppliers in the sawing technology market.

TECHNICAL SPECIFICATION

Behringer Eisele VA-L 350 Series For Medium Application Technical Data

| Model | VA-L 350 NC1 | VA-L 350 NC2 | |

| Downfeed system | hydraulic | servo drive | |

| Cutting range | 90° | 90° | |

| Saw blade standard Ø | [mm] | 350 | 350 |

| Round | [mm] | 115 | 115 |

| Rectangular | [mm] | 200 x 70 | 200 x 70 |

| Square | [mm] | 105 x 105 | 105 x 105 |

| RPM | [min-1] | 800 - 4200 | 800 - 4200 |

| Drive power | [kW] | 15 | 15 |

| Feeding length single stroke | [mm] | 970 | 970 |

| Max. feed rate | [mm/sec] | 800 | 1000 |

| Dimensions L x W x H without tunnel on infeed side |

[mm] | 1925 x 2660 x 2740 | 2460 x 2550 x 1850 |

| Weight | [kg] | ca. 1250 | ca. 1550 |

Behringer Eisele VA-L 560 Series For Heavy Duty Application Technical Data

| Model | VA-L 560 NC1 | VA-L 560 NC2 | |

| Downfeed system | hydraulic | servo drive | |

| Cutting range | 90° | 90° | |

| Saw blade standard Ø | [mm] | 560 | 560 |

| Round | [mm] | 200 | 200 |

| Rectangular | [mm] | 300 x 150 | 300 x 150 |

| Square | [mm] | 170 x 170 | 170 x 170 |

| RPM | [min-1] | 800 - 3200 | 800 - 3200 |

| Drive power | [kW] | 26 | 26 |

| Feeding length single stro | [mm] | 970 | 970 |

| Max. feed rate. | [mm/sec] | 800 | 1000 |

| Dimensions L x W x H without tunnel on infeed side |

[mm] | 2200 x 2650 x 2740 | 2460 x 2550 x 1850 |

| Weight | [kg] | ca. 1800 | ca. 2100 |

Request a Quote

Request A Quote

Please complete the below form to receive further information.