- Home

- Products

- Grinding & Polishing

- Chennai Metco Bainline Twin Belt Grinder - Wet

If you want to find out more about

Chennai Metco Bainline Twin Belt Grinder - Wet

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

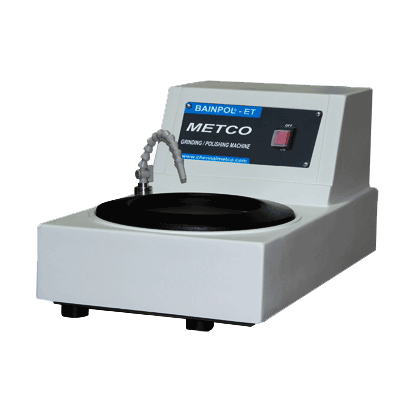

In the metallography process, the next step after the specimen is fitted and properly sized (with any Chennai Metco BAINCUT models) will be preparing the coarse surface of the specimen. Chennai Metco Bainline Twin Belt Grinder - Wet is a fine grinding machine for wet application for flat coarse grinding before fine grinding, you can work with 60, 80, or 120 grit after cutting or molding operation to remove surface imperfections. Thanks to its dual belt grinding feature, you can set separate grit on each end without the hassle to have an additional machine. The fine result is also highly repetitive and predictable to remove light metallurgical damage in the specimen surface induced during cut-off operation. Alternatively, for dry grinding applications, you might also want to consider Chennai Metco Bainline. After the specimen is fine enough, the next step will be using the Chennai Metco BAINPOL VTD for variable speed Polisher / Grinder of the specimen (which can be operated and polished freehand). BAINPOL VTD works to grind and polish finer abrasive particles until the desired surface quality is ready for chemical etching so that the metallographic structure of the specimen can be observed in detail with Vision engineering TIM5 or digital, optical, or electron microscopy. Chennai Metco Twin Belt Grinder - Wet Features: Two grinding belts, Water cooling mechanism belt centering, Anticorrosion M.S Base with powder-coated SS cover Grinding belts: 100X915 mm Spindle Speed 1400 rpm Electrical Interlock System, Water Connection 1xR 1/2", and recirculation Water Valve: Right & Left for even material removal Compact tabletop dimension T-slot table, Cam Vise for easy operation

In the metallography process, the next step after the specimen is fitted and properly sized (with any Chennai Metco BAINCUT models) will be preparing the coarse surface of the specimen. Chennai Metco Bainline Twin Belt Grinder - Wet is a fine grinding machine for wet application for flat coarse grinding before fine grinding, you can work with 60, 80, or 120 grit after cutting or molding operation to remove surface imperfections.

Thanks to its dual belt grinding feature, you can set separate grit on each end without the hassle to have an additional machine. The fine result is also highly repetitive and predictable to remove light metallurgical damage in the specimen surface induced during cut-off operation. Alternatively, for dry grinding applications, you might also want to consider Chennai Metco Bainline.

After the specimen is fine enough, the next step will be using the Chennai Metco BAINPOL VTD for variable speed Polisher / Grinder of the specimen (which can be operated and polished freehand). BAINPOL VTD works to grind and polish finer abrasive particles until the desired surface quality is ready for chemical etching so that the metallographic structure of the specimen can be observed in detail with Vision engineering TIM5 or digital, optical, or electron microscopy.

Chennai Metco Twin Belt Grinder - Wet Features:

- Two grinding belts, Water cooling mechanism belt centering,

- Anticorrosion M.S Base with powder-coated SS cover

- Grinding belts: 100X915 mm

- Spindle Speed 1400 rpm

- Electrical Interlock System, Water Connection 1xR 1/2", and recirculation

- Water Valve: Right & Left for even material removal

- Compact tabletop dimension

- T-slot table, Cam Vise for easy operation

Overview

Built to last

Chennai Metco belt grinders are sturdily built with spartan electric motors enclosed with rigid casing and corrosion proof FRP cabine, resulting in lower noise level and high reliability to be used in various working environments

Customer value

Chennai Metco provides the complete solution for metallography preparation and metallurgy inspection by various methods of grinding, polishing, and etching. Your productivity in using Chennai Metco machine is also covered with 2 years of manufacturer warranty

TECHNICAL SPECIFICATION

Chennai Metco Bainline Twin Belt Grinder - Wet features:

1/2HP single phase motor, 1440 RPM

100mm x 915mm Endless belt

Aluminium idler pulley machanism

Easy removable dust cover system

Easy belt change mechanism

Dust receiver

Size : .WxHxD 630 x 250 x 520 mm

Request a Quote

Request A Quote

Please complete the below form to receive further information.