If you want to find out more about

DoALL Penetrator Saw Blade Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

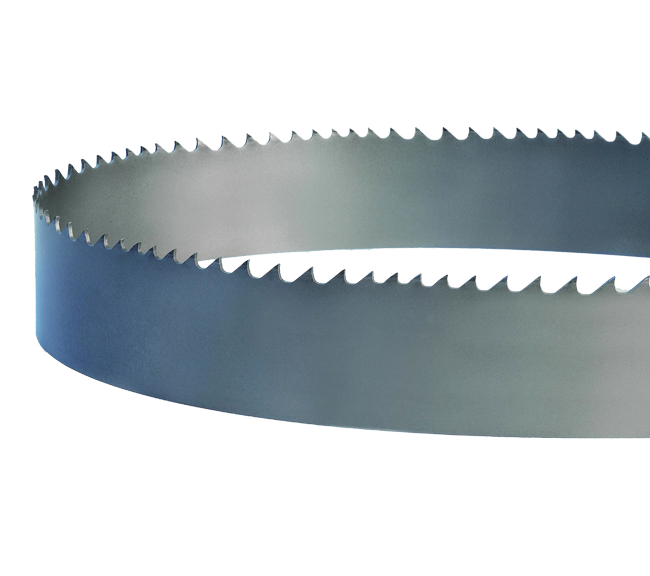

DoALL Penetrator Saw is designed with a high speed steel tooth tips which curved and combined with flexible alloy steel backing material for your reliable precision cutting. DoALL Penetrator Saw is suitable for various bandsaws and reciprocating saws. The DoALL Penetrator Saw Blade teeth are made of high speed steel which bonded with Electron-beam welding to fuse the improved high-strength carbon steel base to a durable chrome-alloy backing material which endure the high temperature of high speed cutting especially when working with high tensile material. This expertise makes all DoALL Penetrator Saw have better combination of cutting speed and durability than rival bimetal blades. The sawing teeth are harder (suitable for many alloy and ferrous material), meanwhile, the backing area of the DoALL Penetrator Saw is softer and also flexible for more resistant to cracking and breaking (which is desirable when you are working with busy queue and minimal cutting fluids). Depends on your machinery set up, DoALL Penetrator Saw Blade performs consistently balanced between power to cut ratio for a cost effective job on cutting solids and heavy wall tubing. DoALL Penetrator Saw Blade is particularly suitable when you need the reliability and versatility in working with oil and gas tube, high compression chemical tube and blanks for CNC fabrication which may varies from each customer. Premium blade for high-production sawing Medium to difficult alloys High production sawing Single, bundle or nest Features M42 HSS tooth Highly positive rake angle curvilinear tooth Benefits Fast cutting, wear resistant blade Designed for production sawing Applications Moderate to difficult alloys on power saws for high production cutting

DoALL Penetrator Saw is designed with a high speed steel tooth tips which curved and combined with flexible alloy steel backing material for your reliable precision cutting. DoALL Penetrator Saw is suitable for various bandsaws and reciprocating saws. The DoALL Penetrator Saw Blade teeth are made of high speed steel which bonded with Electron-beam welding to fuse the improved high-strength carbon steel base to a durable chrome-alloy backing material which endure the high temperature of high speed cutting especially when working with high tensile material. This expertise makes all DoALL Penetrator Saw have better combination of cutting speed and durability than rival bimetal blades. The sawing teeth are harder (suitable for many alloy and ferrous material), meanwhile, the backing area of the DoALL Penetrator Saw is softer and also flexible for more resistant to cracking and breaking (which is desirable when you are working with busy queue and minimal cutting fluids).

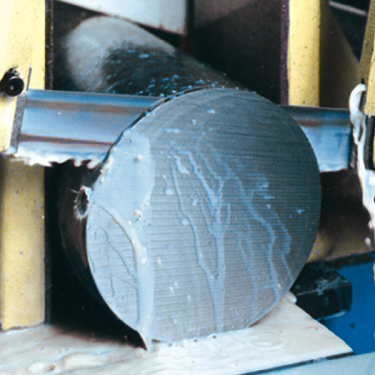

Depends on your machinery set up, DoALL Penetrator Saw Blade performs consistently balanced between power to cut ratio for a cost effective job on cutting solids and heavy wall tubing. DoALL Penetrator Saw Blade is particularly suitable when you need the reliability and versatility in working with oil and gas tube, high compression chemical tube and blanks for CNC fabrication which may varies from each customer.

Premium blade for high-production sawing

- Medium to difficult alloys

- High production sawing

- Single, bundle or nest

Features

- M42 HSS tooth

- Highly positive rake angle curvilinear tooth

Benefits

- Fast cutting, wear resistant blade

- Designed for production sawing

Applications

Moderate to difficult alloys on power saws for high production cutting

Overview

Customer values

Built to perfoms

TECHNICAL SPECIFICATION

DoALL Penetrator Saw Blade Ordering Guide:

|

Inch |

Single & Multi Pitch |

Metric |

|||||||||||

|

Teeth per Inch |

|||||||||||||

|

Width |

Gage |

0.8-1.2 |

1-1.3 |

1-1.5 |

1.3 |

1.5-2 |

2 |

2-3 |

3-4 |

4-6 |

5-8 |

Width |

Gage |

|

1 |

0.035 |

● |

● |

● |

● |

27 |

0.9 |

||||||

|

1-1/4 |

0.042 |

● |

● |

● |

● |

● |

● |

34 |

1.1 |

||||

|

1-1/2 |

0.050 |

● |

● |

● |

● |

41 |

1.3 |

||||||

|

2 |

0.063 |

● |

● |

● |

● |

● |

54 |

1.6 |

|||||

|

2-5/8 |

0.063 |

● |

● |

● |

● |

● |

67 |

1.6 |

|||||

|

3.15 |

0.063 |

● |

● |

80 |

1.6 |

||||||||

*Claw tooth, You can also download DoALL Saw Blade catalogs here

Request a Quote

Request A Quote

Please complete the below form to receive further information.