If you want to find out more about

DoALL Tungsten Carbide Saw Blade STC Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

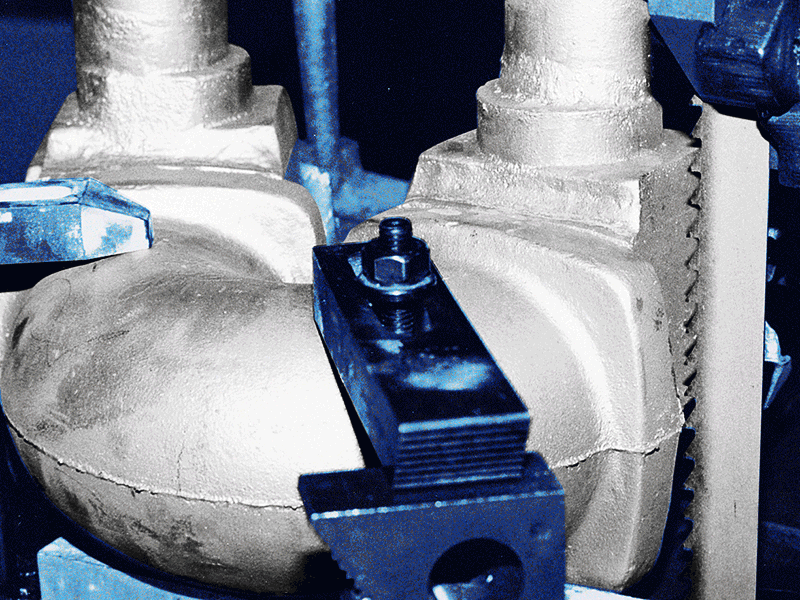

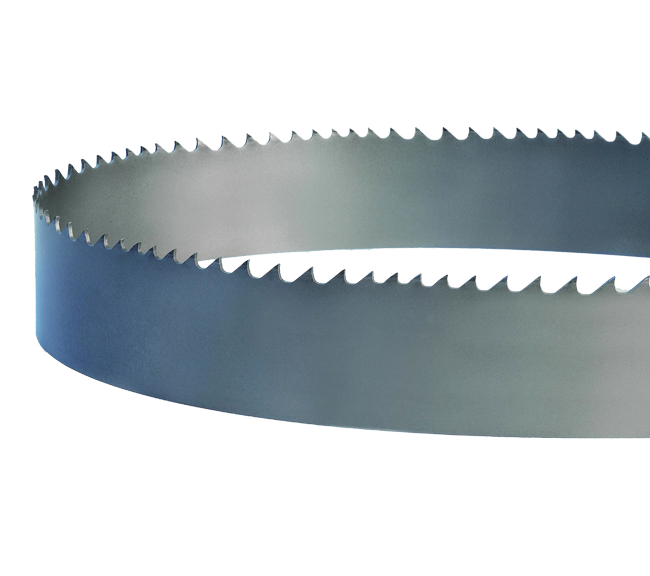

DoALL Tungsten Carbide Saw STC is devised with tungsten carbide tooth, as it can resist high temperatures and is extremely reliable on various bandsaws and reciprocating saws. The DoALL Tungsten Carbide Saw Blade STC overall is two times stiffer than regular steel, with a Young's modulus of approximately 530–700 GPa and is much denser than any regular steel even titanium. DoALL Tungsten Grit Saw Blade STC is very abrasion resistant and withstand higher temperatures than standard high speed steel saw. Depends on your machinery set up, DoALL Tungsten Carbide Saw Blade STC performs consistently balanced between power delivery versus cutting ratio for a cost effective jobs. DoALL Tungsten Grit Saw Blade STC maintain a sharp cutting edge better on cutting medium-abrasive workpiece made of aluminum, fiberglass, resin and ceramic. DoALL Tungsten Carbide Saw Blade STC allows a faster rate of cutting and economic especially when you are working with aluminium casting, fiber making industry and fishing-marine tool fabrication. For cutting highly abrasive material with tougher properties such as silica, granite and gems you can opt for DoALL Diamoond Saw Blade Series Features Tungsten Carbide tooth Positive rake angle Benefits Withstands rapid tool wear caused by fast cutting of highly abrasive materials Applications Abrasive materials that dull Bi-Metal blades rapidly like: aluminium castings, graphite, fiberglass etc

DoALL Tungsten Carbide Saw STC is devised with tungsten carbide tooth, as it can resist high temperatures and is extremely reliable on various bandsaws and reciprocating saws. The DoALL Tungsten Carbide Saw Blade STC overall is two times stiffer than regular steel, with a Young's modulus of approximately 530–700 GPa and is much denser than any regular steel even titanium. DoALL Tungsten Grit Saw Blade STC is very abrasion resistant and withstand higher temperatures than standard high speed steel saw.

Depends on your machinery set up, DoALL Tungsten Carbide Saw Blade STC performs consistently balanced between power delivery versus cutting ratio for a cost effective jobs. DoALL Tungsten Grit Saw Blade STC maintain a sharp cutting edge better on cutting medium-abrasive workpiece made of aluminum, fiberglass, resin and ceramic. DoALL Tungsten Carbide Saw Blade STC allows a faster rate of cutting and economic especially when you are working with aluminium casting, fiber making industry and fishing-marine tool fabrication. For cutting highly abrasive material with tougher properties such as silica, granite and gems you can opt for DoALL Diamoond Saw Blade Series

Features

- Tungsten Carbide tooth

- Positive rake angle

Benefits

- Withstands rapid tool wear caused by fast cutting of highly abrasive materials

Applications

Abrasive materials that dull Bi-Metal blades rapidly like: aluminium castings, graphite, fiberglass etc

Overview

Built to perfoms

Customer value

TECHNICAL SPECIFICATION

DoALL Tungsten Carbide Saw Blade STC Ordering Guide:

| Metric | STC | ||

| Width | Gauge | 3 | |

| 10 | 0,6 | 305-015S | |

| 13 | 0,6 | 305-020S | |

| 20 | 0,9 | 305-025S | |

| 27 | 0,9 | 305-045S | |

| 305-029R | |||

| 34 | 1,1 | 305-326R | |

| 41 | 1,3 | 305-375R | |

| S | = Straight set | ||

| R | = Raker set | ||

Request a Quote

Request A Quote

Please complete the below form to receive further information.