- Home

- Products

- Leak Testing & Flow Measurement

- Leak Tester

- Leak Tester CETATEST 715

If you want to find out more about

Leak Tester CETATEST 715

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

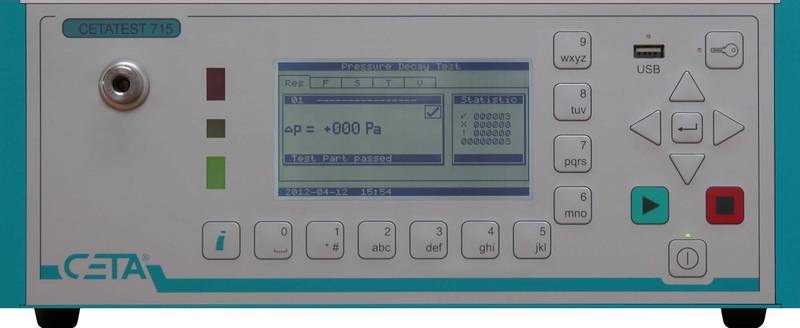

The CETATEST 715 is devised as a fully automatic working leak tester for the detection of leak parts within the cycle time of the production process. Ceta Leak Tester CETATEST 715 works precisely by sensing inputs from its one channel air compressor with at least of 6 - 10 bar and 0.5 bar above test pressure resp. 50 mbar under evacuation pressure (ISO 8573-1) towards the workpiece in such a way that your product can be tested on production line (with or without testing jig). Then, the value of tested workpiece is stored within its internal memory. The cost-effective CETATEST 715 leak detector also provide data output via USB which then can be conveniently saved into a USB flash drive for traceable data record or further analysis of acceptable parameter via CETA PC software and spreadsheet as well. Compared to Ceta Leak Tester CETATEST XS, the CETATEST 715 leak detector are equipped for mid range of 10.000 Pa and detailed mode of testing. This innovative tester measure large leakages by test modes of “test of closed component” and “dynamic pressure test” which can also be integrated on demand. Your investment on Ceta Leak Tester CETATEST 715 will lead your way to unlocks higher level of precision in detecting very small ratios of test part volumes on mass production system. Your operator can simply follow your parameter of programmable test with pass-faill decision by seeing the measured value on its LCD Screen responsibly. Due to its reliable accuracy within an automatic approach, this instrument's versatility is highly regarded by many end user in the inspection of sanitary armatures, plastic weldings, ball valves, from any oil and gas tank quality inspection, aerospace engine parts, food and beverages packaging, automotive turbocharger units, liquid - pharmaceutical packaging, turbochargers, medical equipment, mechatronics, pneumatic workpiece and many more. Ceta Leak Tester CETATEST 715 Features: Piezo-resistive gauge pressure sensor Measurement range of Max. 10,000 Pa, depending on the test pressure (resolution: 1 Pa) Unit of measurements are Pa, hPa, Pa/s, hPa/s, psi, psi/s, ml/min, ml/h, l/min, mbar l/s Can also be combined with mechanical pressure regulator and other set of pressure gauge as well. Input of compressed air supply with 6 mm plug-in fitting and optionally up to three pneumatically driven outputs. Delivered with with CE certificate and DAkkS calibration certificate withhout additional cost. Detailed result statistics, cycle counter, indicator for service intervals, countdown indicator, registration of parameter change, recording of measurement series and measurement curves, Dynamic Link Library (DLL) for RS-232 interface programming Optimised for leak testing of various test parts in high speed production cycles.

The CETATEST 715 is devised as a fully automatic working leak tester for the detection of leak parts within the cycle time of the production process. Ceta Leak Tester CETATEST 715 works precisely by sensing inputs from its one channel air compressor with at least of 6 - 10 bar and 0.5 bar above test pressure resp. 50 mbar under evacuation pressure (ISO 8573-1) towards the workpiece in such a way that your product can be tested on production line (with or without testing jig). Then, the value of tested workpiece is stored within its internal memory. The cost-effective CETATEST 715 leak detector also provide data output via USB which then can be conveniently saved into a USB flash drive for traceable data record or further analysis of acceptable parameter via CETA PC software and spreadsheet as well.

Compared to Ceta Leak Tester CETATEST XS, the CETATEST 715 leak detector are equipped for mid range of 10.000 Pa and detailed mode of testing. This innovative tester measure large leakages by test modes of “test of closed component” and “dynamic pressure test” which can also be integrated on demand.

Your investment on Ceta Leak Tester CETATEST 715 will lead your way to unlocks higher level of precision in detecting very small ratios of test part volumes on mass production system. Your operator can simply follow your parameter of programmable test with pass-faill decision by seeing the measured value on its LCD Screen responsibly. Due to its reliable accuracy within an automatic approach, this instrument's versatility is highly regarded by many end user in the inspection of sanitary armatures, plastic weldings, ball valves, from any oil and gas tank quality inspection, aerospace engine parts, food and beverages packaging, automotive turbocharger units, liquid - pharmaceutical packaging, turbochargers, medical equipment, mechatronics, pneumatic workpiece and many more.

Ceta Leak Tester CETATEST 715 Features:

- Piezo-resistive gauge pressure sensor

- Measurement range of Max. 10,000 Pa, depending on the test pressure (resolution: 1 Pa)

- Unit of measurements are Pa, hPa, Pa/s, hPa/s, psi, psi/s, ml/min, ml/h, l/min, mbar l/s

- Can also be combined with mechanical pressure regulator and other set of pressure gauge as well.

- Input of compressed air supply with 6 mm plug-in fitting and optionally up to three pneumatically driven outputs.

- Delivered with with CE certificate and DAkkS calibration certificate withhout additional cost.

- Detailed result statistics, cycle counter, indicator for service intervals, countdown indicator, registration of parameter change, recording of measurement series and measurement curves, Dynamic Link Library (DLL) for RS-232 interface programming

- Optimised for leak testing of various test parts in high speed production cycles.

Overview

Customer value

Every CETA Test product is manufactured to the strictest standard of DIN ISO 9001:2008, DIN EN ISO 17025, while its “automatic function control” is registered with patent No. 100 45 472. Your reliability on Ceta Test line of quality instruments are also covered with 3 years of extendable warranty

Build to last

For more than 25 years CETA Testsysteme GmbH has been pioneering physical test instrument for the measurement of leaks and flow rates with gas and air application for various industrial testing. Ceta test's line of innovative instruments are devised for your mass production capabilities

TECHNICAL SPECIFICATION

Ceta Leak Tester CETATEST 715 Ordering Guide:

| Operating method | One-channel operation |

| Signal processing | Fast 24-Bit-A/D-ConverterReal-time processing of the measurement signals |

| Valve types | Depending on the application: sliding valve or poppet valve |

| Processing | Real time microcontroller system, 16-Bit µC / 40 MHz |

| Sensors | Relative pressure sensor |

| Measurement ranges | Max. 10,000 Pa, depending on the test pressure (resolution: 1 Pa);other ranges on request |

| Result units | Pa, daPa, hPa, Pa/s, daPa/s, hPa/s, psi, psi/s, ml/min, ml/h, l/min, mbar I/s |

| Electronically regulated test pressure ranges | -1 bar, 200 mbar, 1 bar, 10 barnegative gauge pressure and positive gauge pressure ranges can be combined, other pressures and mechanical pressure regulator on request |

| Test modes | Pressure loss measurement, dynamic pressure test (option), test of closed components (option) |

| Test options | Prefill (multiple filling), program series, smooth filling, analysis of the filling and stabilizing curve, consecutive zero results, variable zero point, test repetition/automatic test time adjustment, free programmable control valves for each program |

| System control | Supply pressure monitoring |

| Programmable test phases | Delay, pre-filling, filling, stabilising, measuring, venting; reservoir filling, flooding, re-filling |

| Test mode specific limits | Prefill pressure, filling pressure, test part specific reject and rework levels |

| Handling | Intuitive menu including password protected user levels |

| Parameter Memory | 64 individual parameter driven test programs with alpha-numeric program namesParameters of the test programs can be exported resp. imported via the test device interfaces or by usage of a USB storage device |

| Power Supply & Power Consumption | 100 – 240 V AC, 47 – 63 Hz, 0.6 – 0.3 A depending on stage of expansion max. 60 W |

| Compressed air supply | 6 - 10 bar and 0,5 bar above test pressure resp. 50 mbar under evacuation pressure (ISO 8573-1) |

| Pneumatic connection | Input (compressed air supply): 6 mm plug-in fitting Port for test part: 3 x 1.7 mm fitting, 3 mm clamping ring [option] Up to three pneumatically driven outputs [option] |

| Dimension and Weight | Width: 345 mm, Height: 145 mm (3U), Depth: 435 mm Weight 10 Kg |

| Standard Delivery | Special packing, power cord, operating manual and documentation on CD, declaration of conformity (CE), calibration certificate, D-Sub-plug including cable for inputs and outputs (PLC-communication) |

| Optional Accessories | Filter combination, standard leak, leak tight 3/2-way-valve, RS-232 / Ethernet-adapter, control- and evaluation software, more in the CETA accessories catalogue |

| Notes:The CETATEST 715 is a fully automatic working leak tester for the detection of untight parts within the cycle time of the production process. The leak tester uses agauge pressure sensor and has a large measurement range. The pressure loss caused by the leakage in the test part is measured. Therefore the CETATEST 715 is especially qualified for the simple testing of parts with large leakages |

To serve your interest on Ceta Leak Tester CETATEST 715,

kindly contact our sales department.

Request a Quote

Request A Quote

Please complete the below form to receive further information.