- Home

- Products

- Force & Torque

- Torque Gauges

- Shimpo Bottle Cap Torque Testing Unit DSP-5E

If you want to find out more about

Shimpo Bottle Cap Torque Testing Unit DSP-5E

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Shimpo DSP-5E (combined with Shimpo TNX Series, Shimpo TNP Series, or Shimpo TNJ Series) is devised to semi-automatically measure opening torques of caps, lids, and screws of various containers, such as cosmetics, medical products, and beverages, as well as the tightening force of valves. Once torque tolerances have been defined, the cap torque tester is used as a torque control device on the final product. If the measurement is out of the limits, the capping machine needs to be adjusted. Shimpo Motorized Torque Testing Unit DSP-5E could be used as a destructive tester to identify if there is any material weakness of the packaging during the screwing of cap process. Furthermore, the stand tester also allows defining the torque tolerances of the capping machine. The lower torque limit is considered as the minimum pressure of the cap to avoid any leak of the product. For better result, the Shimpo's DSP-5E torque tester needs to be combined with a leak test with a secure seal analyzer. The higher torque limit is the maximum torque the customer can apply to open or close the product's cap. Your investment on Shimpo Motorized Torque Testing Unit DSP-5E will allow you to work on appropriate sampling checks in production line because motorizing manual opening torque tests eliminates the variation of measurement torques generated by human error. Depending on the production process, it could be necessary to control the opening torque, 24hours after the packaging process. Temperature variations can also modify the product characteristic as a result of different torque measurement. Furthermore, an optional rotation angle and speed of the rotation axis for opening torque tests can also be set. Shimpo Motorized Torque Testing Unit DSP-5E Features: Fast action test with motorized precision and manual testing for controlled interference within 5N/m. Sets with key operation (0.5 to 12.5 rpm) suitable to test opening of bottling caps of edible products and chemical products Suitable for cap diameter of 012 to 70mm

Shimpo DSP-5E (combined with Shimpo TNX Series, Shimpo TNP Series, or Shimpo TNJ Series) is devised to semi-automatically measure opening torques of caps, lids, and screws of various containers, such as cosmetics, medical products, and beverages, as well as the tightening force of valves. Once torque tolerances have been defined, the cap torque tester is used as a torque control device on the final product. If the measurement is out of the limits, the capping machine needs to be adjusted.

Shimpo Motorized Torque Testing Unit DSP-5E could be used as a destructive tester to identify if there is any material weakness of the packaging during the screwing of cap process. Furthermore, the stand tester also allows defining the torque tolerances of the capping machine. The lower torque limit is considered as the minimum pressure of the cap to avoid any leak of the product. For better result, the Shimpo's DSP-5E torque tester needs to be combined with a leak test with a secure seal analyzer. The higher torque limit is the maximum torque the customer can apply to open or close the product's cap.

Your investment on Shimpo Motorized Torque Testing Unit DSP-5E will allow you to work on appropriate sampling checks in production line because motorizing manual opening torque tests eliminates the variation of measurement torques generated by human error. Depending on the production process, it could be necessary to control the opening torque, 24hours after the packaging process. Temperature variations can also modify the product characteristic as a result of different torque measurement. Furthermore, an optional rotation angle and speed of the rotation axis for opening torque tests can also be set.

Shimpo Motorized Torque Testing Unit DSP-5E Features:

- Fast action test with motorized precision and manual testing for controlled interference within 5N/m.

- Sets with key operation (0.5 to 12.5 rpm) suitable to test opening of bottling caps of edible products and chemical products

- Suitable for cap diameter of 012 to 70mm

Overview

Customer values

Shimpo Motorized Torque Testing Unit DSP-5E is manufactured to conforms with ISO9001(JQA-1739) since 1998. Shimpo's ranges of force, torque and speed evaluation instruments and accessories are designed for accuracy, practicality and safety operation within 1 year warranty.

Built to last

Founded in 1973, Shimpo is originated from Japan and currently a subsidiary company of NIDEC CORPORATION. Shimpo alog with Tosok has become the world’s dominant provider of small precision tools.

TECHNICAL SPECIFICATION

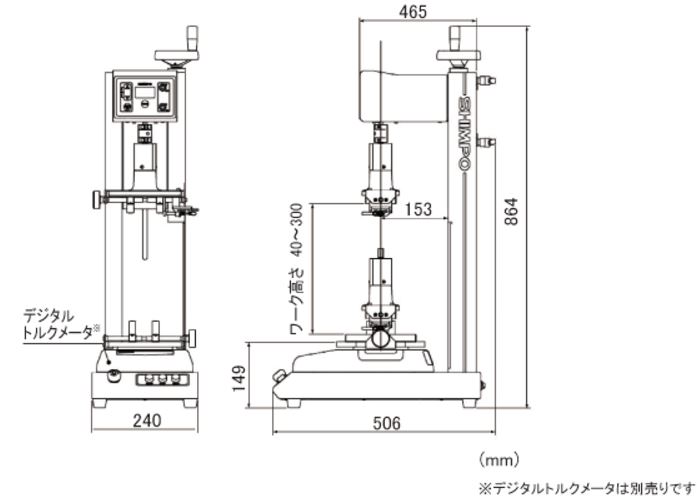

Shimpo Motorized Torque Testing Unit DSP-5E Dimension Guide:

Shimpo Motorized Torque Testing Unit DSP-5E Ordering Guide:

|

Model |

DSP-5E |

|

|

Torque meters that can be installed* |

TNX-0.5, TNX-2, TNX-5 / TNP-0.5, TNP-2, TNP-5 / TNJ-2, TNJ-5 (digital torque meters are optional) |

|

|

Allowable torque |

5N.m |

|

|

Chuck |

Chuck pin 20mm 4 points |

|

|

Supporting cap diameter |

012 to 70mm |

|

|

Chuck system |

Handle / Single operation clamp |

|

|

Work height |

Range |

40 to 300mm |

|

Mechanism |

Adjusts using the handle |

|

|

Display |

LCD display |

Signed 4-digit display (Displays the rotation angle) |

|

Operation mode |

AUTO mode / JOG mode |

|

|

|

Operation |

Sets angle/speed and operates |

|

|

Direction |

Opening (CCW) direction |

|

AUTO mode |

Origin return |

HOME operation (CW) direction |

|

|

Speed setting |

Sets with key operation (0.5 to 12.5 rpm) |

|

|

Angle setting |

Sets with key operation (1 to 1080°) |

|

|

Operation |

JOG operation |

|

JOG mode |

Direction |

Opening (CCW) direction/HOME operation (CW) direction |

|

|

Speed setting |

Sets with key operation (0.5 to 12.5 rpm) |

|

External dimensions |

Width 240 x Depth 506 x Height 864mm |

|

|

Weight (excluding torque meter) |

Approx. 15kg |

|

|

Power supply |

AC100V(50/60Hz) 300VA |

|

|

Operating condition |

Temperature range 0 to 40°C Humidity range 0 to 85%RH |

|

Request a Quote

Request A Quote

Please complete the below form to receive further information.