If you want to find out more about

Sisma Laser Welding SL Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

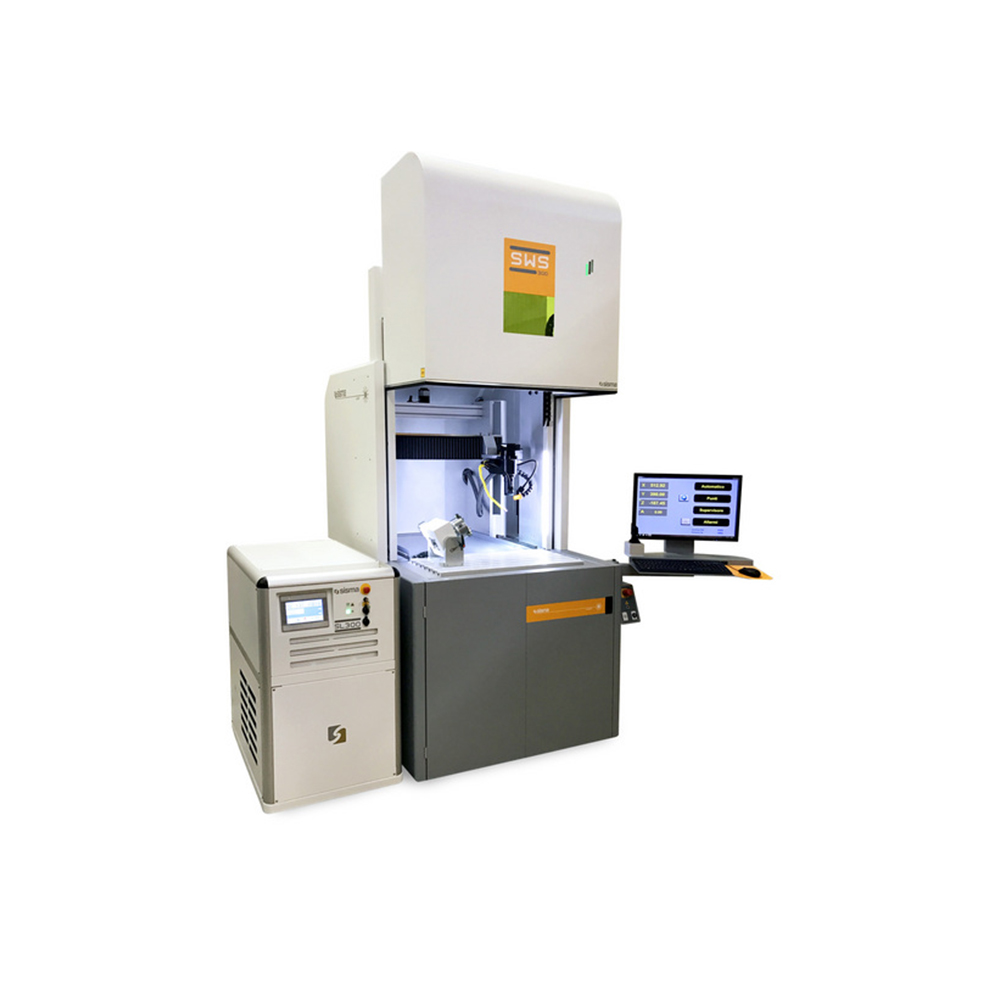

Sisma Laser Welding SL Series are optimized for micro-welding and moulds maintenance with and without filler material on faster rates. Sisma Laser Welding SL Series are intended to bring your company towards higher level of precision at much affordable cost. expressively developed for the automatic welding production process, where high speed and high precision are required. The laser generator, provided with fiber optic and focussing head, can be easily fitted in the production lines. You can also combine this unit to your specific working floor environment. Sisma Laser Welding SL works by utilizing Fiber Ytterbium (Yag) laser beam which emit light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser). Compared to regular Co2 laser machine, Sisma's YAG laser technology produce world's highest accuracy which comes without the need for regular head source maintenance, optical replacement, mixed gas (argon & C02), Co2 nozzle consumables, preassure gauges and excessive fire retardant kit which must be maintained and replaced miticulously. Sisma's laser efficiency will not only save your operating cost but also provide much safer working environment too. Depends on your need of wattage application and budget, the innovative laser unit have 6 selectable model to choose from. Sisma has a wide range of compact machines, from 25 to 300 W, with the possibility of splitting the welding beam, making two welding at the same time. You can easily set up adjustments of the optic head on motorized axes. Laser parameters can be managed through intuitive touch screen that allows the control of the waveform, the diameter of welding and spindle rotation. Sisma know-how together with electronic design techniques guarantee pump system reliability and long lasting duration of lamp. Sisma Laser Welding SL Series are highly regarded on precision medical equipment, jewellery, mechatronics and precision tool-making. Sisma SWA manual welding laser Features: Air cooled up to 35°C of room temperature Possibility of modifying the impulse shape Possibility of programming up to 3 different weldings Pre-set software to facilitate welding of reflecting materials Self-diagnosis and self-testing function Alignment without opening resonator, micrometric adjustment of the fiber fitting Designed to be a superior laser system with user friendly software for micro-welding on precision plastic injection mould, stamping dies, precision heavy press brake dies, engraving and finishing on tough metals. Sisma laser machine is the only reasonable upgrades to replace your classic EDM machine whereby a desired shape is obtained using unstable electrical discharges which usually creates more headache and clients' complaints. Innovative contents displayed on interactive LCD screen. Conceived for a long service life without excessive cost on consumables and maintenance. Can also be ordered with magnetic vise, cooling panel and other accessories to support you on working with shift and busy queue.

Sisma Laser Welding SL Series are optimized for micro-welding and moulds maintenance with and without filler material on faster rates. Sisma Laser Welding SL Series are intended to bring your company towards higher level of precision at much affordable cost. expressively developed for the automatic welding production process, where high speed and high precision are required. The laser generator, provided with fiber optic and focussing head, can be easily fitted in the production lines. You can also combine this unit to your specific working floor environment.

Sisma Laser Welding SL works by utilizing Fiber Ytterbium (Yag) laser beam which emit light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser). Compared to regular Co2 laser machine, Sisma's YAG laser technology produce world's highest accuracy which comes without the need for regular head source maintenance, optical replacement, mixed gas (argon & C02), Co2 nozzle consumables, preassure gauges and excessive fire retardant kit which must be maintained and replaced miticulously. Sisma's laser efficiency will not only save your operating cost but also provide much safer working environment too.

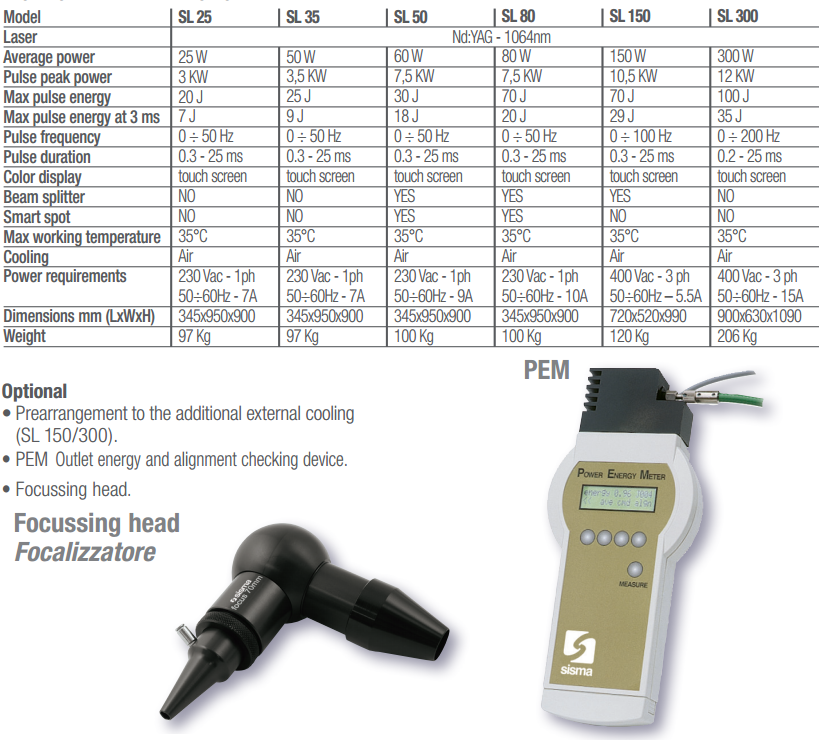

Depends on your need of wattage application and budget, the innovative laser unit have 6 selectable model to choose from. Sisma has a wide range of compact machines, from 25 to 300 W, with the possibility of splitting the welding beam, making two welding at the same time. You can easily set up adjustments of the optic head on motorized axes. Laser parameters can be managed through intuitive touch screen that allows the control of the waveform, the diameter of welding and spindle rotation. Sisma know-how together with electronic design techniques guarantee pump system reliability and long lasting duration of lamp. Sisma Laser Welding SL Series are highly regarded on precision medical equipment, jewellery, mechatronics and precision tool-making.

Sisma SWA manual welding laser Features:

- Air cooled up to 35°C of room temperature

- Possibility of modifying the impulse shape

- Possibility of programming up to 3 different weldings

- Pre-set software to facilitate welding of reflecting materials

- Self-diagnosis and self-testing function

- Alignment without opening resonator, micrometric adjustment of the fiber fitting

- Designed to be a superior laser system with user friendly software for micro-welding on precision plastic injection mould, stamping dies, precision heavy press brake dies, engraving and finishing on tough metals.

- Sisma laser machine is the only reasonable upgrades to replace your classic EDM machine whereby a desired shape is obtained using unstable electrical discharges which usually creates more headache and clients' complaints.

- Innovative contents displayed on interactive LCD screen.

- Conceived for a long service life without excessive cost on consumables and maintenance.

- Can also be ordered with magnetic vise, cooling panel and other accessories to support you on working with shift and busy queue.

Overview

Customer value

Built to last

TECHNICAL SPECIFICATION

Sisma Laser Welding SL Series ordering guide:

|

Notes: Constant ray of laser may result in higher temperature and affect the performance. Better circulation of cold air and fumes respirator are advised with pulsed mode operation for a much efficient approach. When you are using the machine with longer working time, make sure to install additional cooling panel to avoid unnecessary down time. |

Request a Quote

Request A Quote

Please complete the below form to receive further information.