If you want to find out more about

Taipu Tapping Machine TP1300 Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

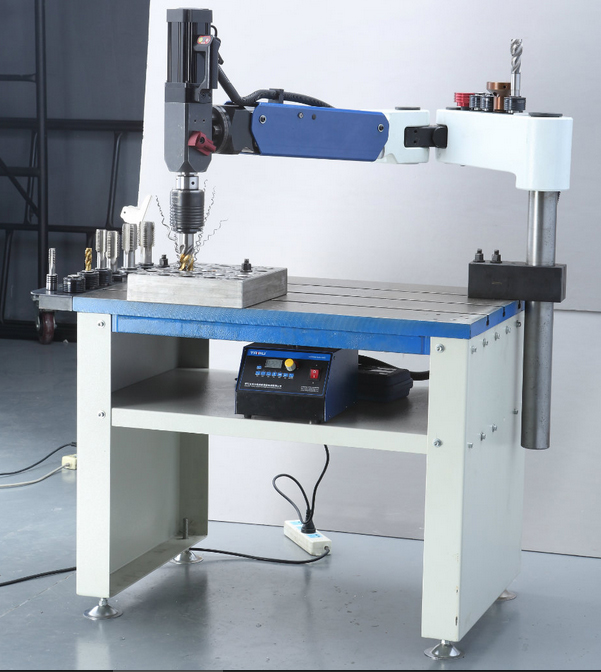

Taipu Tapping Machine TP1300 Series are powered by durable DC motors. The process of cutting or forming threads with its DC motors allows you to easily do programmable torque, consistent speed and flexible tapping by its standard configuration. You can also do both manually vertical or horizontal tapping by its arm floating model. With tapping capacity from M3 to M60, the value tapping set will surely adds versatile application on your factory floor. Compared to air tapping machine, the Taipu's electric powered Tapping Machine TP1300 Series demands lesser fatigue to be operated by your operator as the machine itself works with lesser vibrations and allows simulated and programmable tapping. Furthermore, its fluid locking arm mechanism will surely enable you to work with busy pace without the risk of swarf and metal chips cuts the air hose as in pneumatics. Your operator will find its Quick-change chuck with Φ48 mm is practical as it only need 3 to 5 seconds to initiate a new tool. Depends on the cutting tools application itself, the TP1300 tapping machine should deliver optimum performance at the speed of 150 R.P.M. With proper selection of tooling system, Taipu Tapping Machine TP1300 Series will fare you a better return on investment, especially when you are working with routines on various steel, iron, copper, aluminum, plastic and other materials as well. Taipu Air Tapping Machine TP1300 Series Features: Vertical & horizontal Tapping Machine Floating 360° degree of movement Planetary 2 speed gear for efficient powertrain Programmable speed depth, torque step and simulated manual tapping mode Capacity from M3 to M42 and M60 Quick-change chuck with Φ31mm Stable speed up to 100 R.P.M Working radius of 1300 mm Compact form factor with suficient power of 1.2 KW Can also be ordered with German made tapping bit & colletes

Taipu Tapping Machine TP1300 Series are powered by durable DC motors. The process of cutting or forming threads with its DC motors allows you to easily do programmable torque, consistent speed and flexible tapping by its standard configuration. You can also do both manually vertical or horizontal tapping by its arm floating model. With tapping capacity from M3 to M60, the value tapping set will surely adds versatile application on your factory floor.

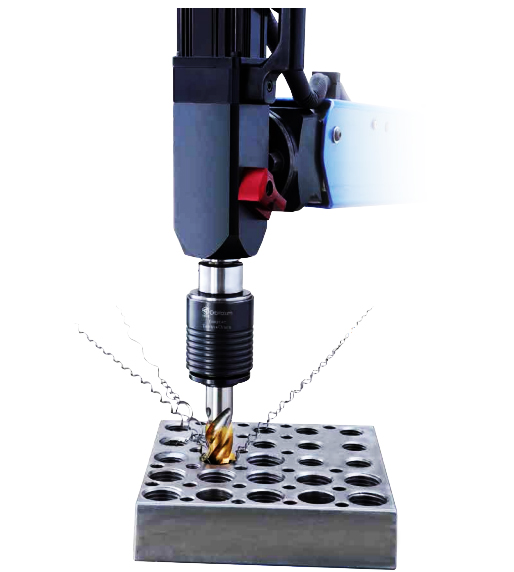

Compared to air tapping machine, the Taipu's electric powered Tapping Machine TP1300 Series demands lesser fatigue to be operated by your operator as the machine itself works with lesser vibrations and allows simulated and programmable tapping. Furthermore, its fluid locking arm mechanism will surely enable you to work with busy pace without the risk of swarf and metal chips cuts the air hose as in pneumatics. Your operator will find its Quick-change chuck with Φ48 mm is practical as it only need 3 to 5 seconds to initiate a new tool.

Depends on the cutting tools application itself, the TP1300 tapping machine should deliver optimum performance at the speed of 150 R.P.M. With proper selection of tooling system, Taipu Tapping Machine TP1300 Series will fare you a better return on investment, especially when you are working with routines on various steel, iron, copper, aluminum, plastic and other materials as well.

Taipu Air Tapping Machine TP1300 Series Features:

- Vertical & horizontal Tapping Machine

- Floating 360° degree of movement

- Planetary 2 speed gear for efficient powertrain

- Programmable speed depth, torque step and simulated manual tapping mode

- Capacity from M3 to M42 and M60

- Quick-change chuck with Φ31mm

- Stable speed up to 100 R.P.M

- Working radius of 1300 mm

- Compact form factor with suficient power of 1.2 KW

- Can also be ordered with German made tapping bit & colletes

Overview

Built to performs

TECHNICAL SPECIFICATION

Taipu Tapping Machine Series Schematic Dimension:

Taipu Tapping Machine TP1300 Series Ordering Guide:

| Model No. |

TP1300-42A(UD) |

TP1300-60A(UD) |

|

Tapping Capacity |

M3-M42 |

M3-M60 |

|

Working Radius (mm) |

1300 |

1300 |

|

Chuck Size (mm) |

Φ48 |

Φ48 |

|

Power (KW) |

1.8 |

2.2 |

|

Speed (r.p.m) |

0-30/0-100 |

0-20/0-100 |

|

N/W (kgs) G/W (kgs) |

100 |

110 |

|

110 |

120 |

|

|

Package size(mm) |

830×780×330 |

830×780×330 |

"U" stand for universal tapping, "D" stand for model with two speed

Request a Quote

Request A Quote

Please complete the below form to receive further information.