If you want to find out more about

Trojan Beta-300 Pro Automatic Cut-off Machine

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Beta-300 Pro Automatic Cut-off Machine Beta-300Pro is an automatic cutting machine equipped with advanced intelligent control and touch screen operation technology. A 3-axis joystick, laser alignment, and large workbench make it easy to operate. The Beta-300Pro is equipped with a variety of cutting methods and techniques to help you achieve superior cut surfaces, even when cutting large samples for heavy-duty applications. Automatic cutting mode allows maximum reproducibility of the cutting process. Features Equipped with 7-inch touch screen and storage of 20 programs. 3-axis X-Y-Z automatic cutting, laser alignment. Capable of displaying cutting routines and quick positions. Different cutting modes can meet different cutting needs. Intelligently adjust and optimize cutting progress according to material hardness and preset cutting current. T-slot vise that is easy to clamp and fits a variety of shapes. Pulsating Cutting – Automatically adjusts cutting speed for better surface quality. Auto detect if shutdown. Application Ferrous metal, non-ferrous metal. Castings, heat treatment samples, forgings. Semiconductor, ceramics (with special cutt-off wheels). Other metal and non-metal materials. Touch Screen Appereance. Vise Clamping Equipment. Control Panel Wiring. Cutting Wheel & Laser Alignment.

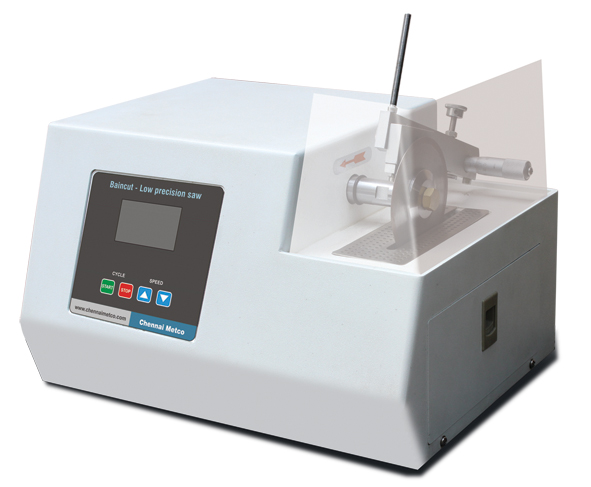

Beta-300 Pro Automatic Cut-off Machine

Beta-300Pro is an automatic cutting machine equipped with advanced intelligent control and touch screen operation technology. A 3-axis joystick, laser alignment, and large workbench make it easy to operate. The Beta-300Pro is equipped with a variety of cutting methods and techniques to help you achieve superior cut surfaces, even when cutting large samples for heavy-duty applications. Automatic cutting mode allows maximum reproducibility of the cutting process.

Features

- Equipped with 7-inch touch screen and storage of 20 programs.

- 3-axis X-Y-Z automatic cutting, laser alignment.

- Capable of displaying cutting routines and quick positions.

- Different cutting modes can meet different cutting needs.

- Intelligently adjust and optimize cutting progress according to material hardness and preset cutting current.

- T-slot vise that is easy to clamp and fits a variety of shapes.

- Pulsating Cutting – Automatically adjusts cutting speed for better surface quality.

- Auto detect if shutdown.

Application

- Ferrous metal, non-ferrous metal.

- Castings, heat treatment samples, forgings.

- Semiconductor, ceramics (with special cutt-off wheels).

- Other metal and non-metal materials.

Touch Screen Appereance.

Vise Clamping Equipment.

Control Panel Wiring.

Cutting Wheel & Laser Alignment.

Overview

TECHNICAL SPECIFICATION

|

Model |

Beta 300 Pro |

|

|

Wheel |

Speed |

800~3500rpm |

|

Dia. |

Ø300mm |

|

|

Arbor size |

32mm |

|

|

Electronic |

Input |

3x380V/50Hz+ground line |

|

Power

|

Total power 5.0KW, Cutting power 4KW |

|

|

Safety |

Emergency stop |

Press to disconnect the control loop and main power |

| Safety lock |

It can not start while the door open and the door can not open during cutting |

|

|

Joystick |

Should operated by 2 hands simultaneously |

|

|

Over Current Protection |

The machine will be stopped when the current over loaded |

|

| Cutting Force |

Monitor the cutting force, the machine will stop if the cutting force on theblade higher than thesafe value. |

|

| Control |

Display / Control |

7”touch screen |

|

Z-axis (Chop Cutting) |

Automatically: 0.01~5mm/s |

|

|

Y-axis (Table Feeding) |

Automatically: 0.01~5mm/s |

|

|

X-axis (Paralleled Cutting) |

Motor Control by Joystick |

|

| Cooling Tank |

Capasity Volume |

80L |

|

Dimensions |

720*550*550mm(W*D*H, with pump installed) |

|

|

Connector |

Water inlet: Ø19 inner diameter high pressure pipe; |

|

|

Water way |

2 Channels, flow: 50L/min |

|

|

Intelligent Cutting |

Cutting Mode |

Y-axial(Table-feed cutting) /Z-axial(Chop cutting)/Y-Z segmented cutting |

|

Speed adjustment method |

Constant speed cutting / pulse cutting / automatic speed adjustment |

|

|

Laser alignment |

Yes |

|

|

Auto find the origin |

Yes |

|

|

Auto detect whether cut-off |

The machine will stop automatically after cut-off without setting the cutting depth |

|

| Cutting Capacity |

Max. dia |

Ø110mm |

|

Max. Square section |

80*200mm |

|

|

Table |

Dimension |

280*536mm |

|

T-slot |

12mm |

|

|

Travel |

Z-axis :150mm ;Y-axis :200mm ;X-axis:80mm; |

|

|

Dimension |

W*D*H |

979*940*1535mm(Close), 979*940*1881mm(Open) |

|

Weight |

Cutter |

376kg |

|

The water tank |

34kg |

|

Request a Quote

Request A Quote

Please complete the below form to receive further information.