If you want to find out more about

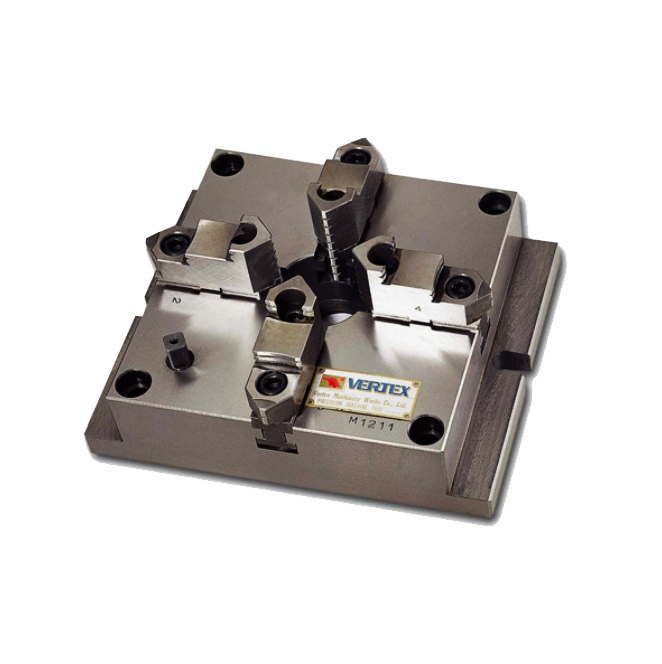

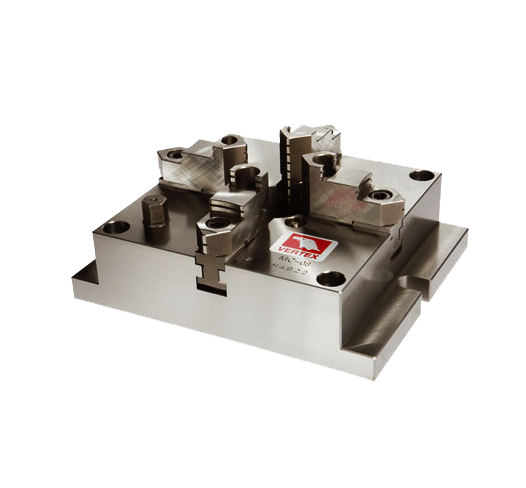

Vertex Machining Jaw Chuck VMJ Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Vertex Machining Jaw Chuck VMJ Series as a self-centering chuck or scroll chuck, uses 4 dogs (usually called jaws), interconnected via a scroll gear (scroll plate), to hold onto a tool or workpiece. Compared with conventional 3 Jaws model, Vertex Machining Jaw Chuck VMJ Series are best suited to grip circular or hexagonal cross-sections when very fast, reasonably accurate (±0.005 inch [0.125 mm] TIR) centering is desired to your fabrication specifiication Vertex Machining Jaw Chuck VMJ Series can be used to further improve the concentricity after the workpiece has been gripped by the scroll jaws. Vertex Machining Jaw Chuck VMJ Series can last you many years as they were fabricated from high tensile alloy which requires medium lubrication on the maintenance to make sure the jaws slide with lesser friction. This feature is meant to combine the precision, speed and ease of the scroll plate's self-centering with the run-out eliminating chatter and excessive vibration. Vertex Machining Jaw Chuck VMJ Series are often used on various milling vise and indexing heads. Your work-piece are gripped firmly by the formed jaws. ensuring high precision (Deviation: within 0.03mm). Vertex Machining Jaw Chuck VMJ Series Features: Use froming rings (jaw locks) to form the soft-jaws. Large work pieces can be held tight with the low profile vise body. Able to grip square works by using this chuck as a two-way jaw unit, *The fixed jaw (optional) is necessary. Longitudinal works can alse be gripped by using the bore of this chuck with the cover removed. A dust cover is provided and this keeps the shavings from entering the machine. The handle is set on the face and does not interfere with the table. A number of chucks can be used together.

Vertex Machining Jaw Chuck VMJ Series as a self-centering chuck or scroll chuck, uses 4 dogs (usually called jaws), interconnected via a scroll gear (scroll plate), to hold onto a tool or workpiece. Compared with conventional 3 Jaws model, Vertex Machining Jaw Chuck VMJ Series are best suited to grip circular or hexagonal cross-sections when very fast, reasonably accurate (±0.005 inch [0.125 mm] TIR) centering is desired to your fabrication specifiication

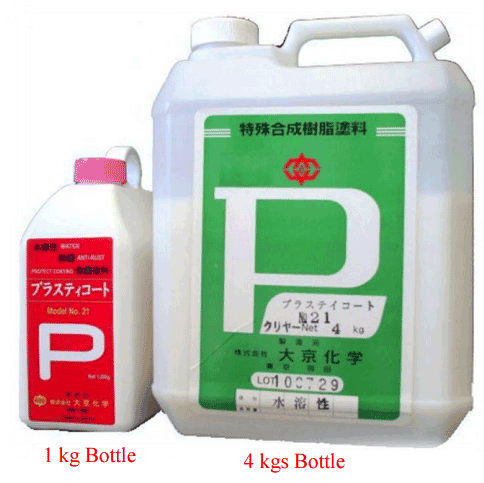

Vertex Machining Jaw Chuck VMJ Series can be used to further improve the concentricity after the workpiece has been gripped by the scroll jaws. Vertex Machining Jaw Chuck VMJ Series can last you many years as they were fabricated from high tensile alloy which requires medium lubrication on the maintenance to make sure the jaws slide with lesser friction. This feature is meant to combine the precision, speed and ease of the scroll plate's self-centering with the run-out eliminating chatter and excessive vibration. Vertex Machining Jaw Chuck VMJ Series are often used on various milling vise and indexing heads. Your work-piece are gripped firmly by the formed jaws. ensuring high precision (Deviation: within 0.03mm).

Vertex Machining Jaw Chuck VMJ Series Features:

- Use froming rings (jaw locks) to form the soft-jaws.

- Large work pieces can be held tight with the low profile vise body.

- Able to grip square works by using this chuck as a two-way jaw unit, *The fixed jaw (optional) is necessary. Longitudinal works can alse be gripped by using the bore of this chuck with the cover removed.

- A dust cover is provided and this keeps the shavings from entering the machine.

- The handle is set on the face and does not interfere with the table. A number of chucks can be used together.

Overview

TECHNICAL SPECIFICATION

Vertex Machining Jaw Chuck VMJ Dimension:

Vertex Machining Jaw Chuck VMJ Series Ordering Guide:

| ORDER NO. | A | B | C | D | E | G | H | I | WEIGHT | CODE NO. |

|

VMJ-6

|

165

|

215

|

144

|

18

|

50

|

26

|

130

|

40

|

13.7

|

5002-240

|

|

VMJ-8

|

200

|

250

|

174

|

18

|

50

|

28

|

160

|

55

|

21.5

|

5002-241

|

|

VMJ-10

|

250

|

310

|

218

|

18

|

60

|

32

|

200

|

70

|

36.1

|

5002-242

|

|

VMJ-12

|

310

|

380

|

274

|

22

|

70

|

40

|

260

|

100

|

61.7

|

5002-243

|

Request a Quote

Request A Quote

Please complete the below form to receive further information.