If you want to find out more about

Widia HC Hydraulic Chuck Sleeves

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

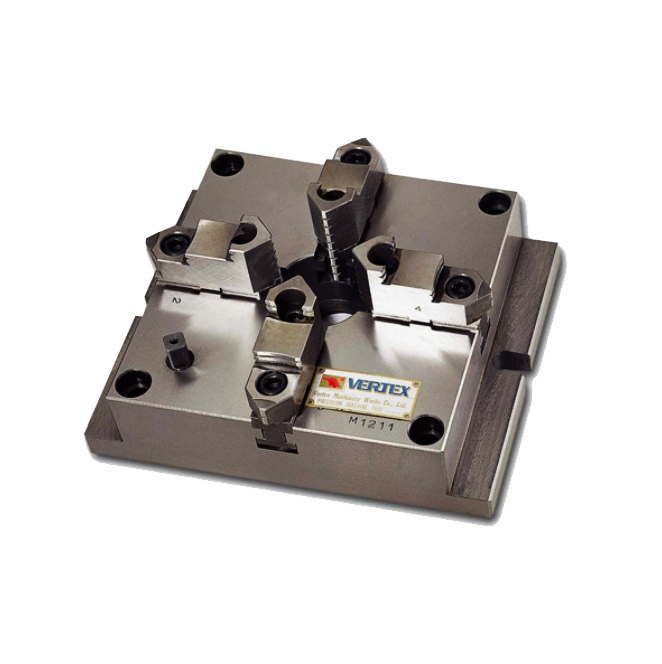

Widia™ offers high-precision ERICKSON Hydraulic Reduction Sleeves which are specially designed for clamping straight cylindrical cutting tool shanks. The self-sealing design enables efficient use of through-coolant cutting tools when the cutting tool shank completely engages the full gripping length of the sleeve. The design features a Four-wall pocket that provides insert stability for accelerated feed rates and increased productivity. Furthermore, the HC collets support through coolant standards for improved tool life, hole finish, and chip removal. There are 6 different models to choose from, Each model is specified with an outer-inner diameter with respective metric or imperial measurement, and for a higher-end model with Safe-Lock and smart coolant feature to accomodate cutting tool shank holding requirement of at least L9 dimension. WDIA collet chuck solution upgrades the fabricator's performance and final part tolerance as well as working faster and saving working hours. Your investment in Widia HC Hydraulic Chuck Sleeves will allow you to work with precision parts demanded by Aerospace, die/mold, and many other industries which encounter high-strength, difficult-to-machine materials requiring high torques, feeds, and forces. Hence, the danger of milling cutters being pulled out of the tool holder as the extreme forces have significantly increased. Widia HC Hydraulic Chuck Sleeves features: One-piece design with slot configuration to seal coolant. Capable of up to 100 bar (1,500 psi) coolant pressure. The cutting tool shank requirement tolerance is h6 and Ra =0,3 µm (12 µ in) surface finish. Maximum collapse is h6, with the cutting tool must be cylindrical and have a through the hole when using coolant. The sleeve must be inserted completely into the hydraulic chuck until the shoulder mates against the hydraulic chuck's front face. Cutting tools must be in full contact with the sleeve bore length (L9). Suitable for fully autonomous operation as the sturdy designs are sufficient in securing workpieces of high-strenght material. PDF catalog on metric can be downloaded here and on inches here (103 MB)

Widia™ offers high-precision ERICKSON Hydraulic Reduction Sleeves which are specially designed for clamping straight cylindrical cutting tool shanks. The self-sealing design enables efficient use of through-coolant cutting tools when the cutting tool shank completely engages the full gripping length of the sleeve. The design features a Four-wall pocket that provides insert stability for accelerated feed rates and increased productivity. Furthermore, the HC collets support through coolant standards for improved tool life, hole finish, and chip removal.

There are 6 different models to choose from, Each model is specified with an outer-inner diameter with respective metric or imperial measurement, and for a higher-end model with Safe-Lock and smart coolant feature to accomodate cutting tool shank holding requirement of at least L9 dimension. WDIA collet chuck solution upgrades the fabricator's performance and final part tolerance as well as working faster and saving working hours.

Your investment in Widia HC Hydraulic Chuck Sleeves will allow you to work with precision parts demanded by Aerospace, die/mold, and many other industries which encounter high-strength, difficult-to-machine materials requiring high torques, feeds, and forces. Hence, the danger of milling cutters being pulled out of the tool holder as the extreme forces have significantly increased.

Widia HC Hydraulic Chuck Sleeves features:

- One-piece design with slot configuration to seal coolant.

- Capable of up to 100 bar (1,500 psi) coolant pressure.

- The cutting tool shank requirement tolerance is h6 and Ra =0,3 µm (12 µ in) surface finish.

- Maximum collapse is h6, with the cutting tool must be cylindrical and have a through the hole when using coolant.

- The sleeve must be inserted completely into the hydraulic chuck until the shoulder mates against the hydraulic chuck's front face.

- Cutting tools must be in full contact with the sleeve bore length (L9).

- Suitable for fully autonomous operation as the sturdy designs are sufficient in securing workpieces of high-strenght material.

PDF catalog on metric can be downloaded here and on inches here (103 MB)

Overview

Customer value

Built to last

TECHNICAL SPECIFICATION

Widia HC Hydraulic Chuck Sleeves with Safe-Lock™ and Smart Coolant (Metric) Ordering Guide:

| Order number | catalog number | D1 | D2 | D | L1 | L9 | V | G3X | G2 | WF | |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

5998607 | 32MHCSFC120M | 12 | 36 | 32 | 2,5 | 41 | 4 | M12 | M6 | 32 |

| 5998608 | 32MHCSFC140M | 14 | 36 | 32 | 2,5 | 41 | 4 | M12 | M6 | 32 | |

| 5998609 | 32MHCSFC160M | 16 | 36 | 32 | 2,5 | 44 | 4 | M12 | M6 | 32 | |

| 5998610 | 32MHCSFC200M | 20 | 36 | 32 | 2,5 | 46 | 4 | M12 | M6 | 32 | |

| 5998751 | 32MHCSFC250M | 25 | 36 | 32 | 2,5 | 47 | 4 | M12 | M6 | 32 | |

|

NOTE: Inserting the cutting tool less than the gripping length (L9) of the sleeve can permanently damage the sleeve and hydraulic chuck. Recommended to clean coolant holes periodically with air. |

|||||||||||

Request a Quote

Request A Quote

Please complete the below form to receive further information.