Dot Peen Marking is one of the most used marking machines for industrial activities. It functions to mark on metallic materials. If you are curious about other forms of marking available, you can read more about marking machines in general in our previous article.

In this article, we will be uncovering the dot peen marking in detail.

What is Dot Peen Marking?

Dot peen marking or often also called dot pin marking is a process of sticking an electromechanically controlled stylus on the surface of a part of the workpiece. Dot peen marking machines are essentially stamping machines that work electromechanically by moving the stylus back and forth and creating indentations on your product. With this machine, you will get a result in the form of a series of stress points that are pressed under the surface, with the size, distance, and shape of the dots that can be adjusted to your needs.

Function of the Dot Peen Marking

(Example of Dot Peen Marking)

The dot peen marking's function is to mark a section with a dotted pattern, with the result in the form of numbers, text, logos, and 2D data matrix codes. The marking process can be completed in just seconds, depending on the size of your part.

Types of Dot Peen Marking Machines

Classified based on their use, dot peen marking machines can be divided into three types, namely:

1. Dot Peen Column Mounted or Benchtop Machine

(SIC Marking Dot Peen Marking Machine E10 C153)

A column mounted dot peen machine or often also called a benchtop dot peen machine is a machine that operates with high power and extreme speed, this is what makes it perfectly accurate. This machine uses electromagnetic technology and can work on workpieces of various shapes, sizes, and surfaces, such as flat, concave, or convex surfaces.

2. Portable Dot Peen Machine

(SIC Marking Portable Marking Gun E10 P123)

A portable dot peen machine or also known as a handheld dot peen machine is a dot peen machine that is easy to use, portable and lightweight. With this machine you can mark large products easily, just by holding the machine and pressing the button. The plate at the front of the machine is in the form of a sturdy aluminum box that is specially designed to be curved to optimize the marking process on flat or cylindrical surfaces, both metal and plastic.

3. Integrated Dot Peen Machine

(SIC Marking Dot Peen Marking Head e10 R i53)

The integrated dot peen marking machine is a dot peen marking machine that can operate automatically with the help of the built-in software or using software compatible with the Windows/Mac operating system. With this machine, your work will be made easier, because they are integrated to an automation system tailored to your requirements, without the need for manual control. This machine has a simple, sleek design and is easy to install.

How Dot Peen Marking Works

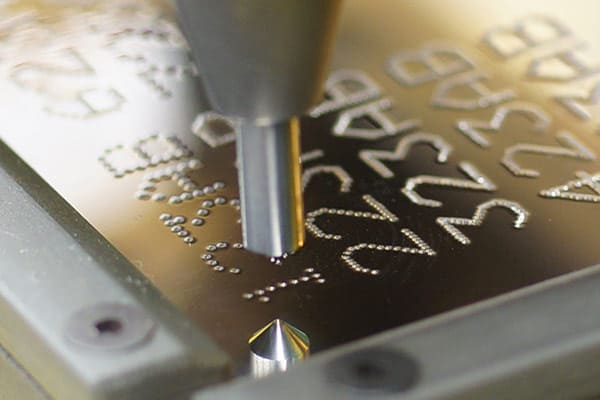

The dot peen marking machine works by using a stylus or a pneumatically driven pin to stamp (peen) the surface of the workpiece to form a series of dots.

(Dot peen marking stylus)

The stylus moves in the X and Y directions to produce a very precise series of dots at a resolution of 0.025 mm. You can control the quality and depth of marking by adjusting the marking settings, air pressure, point distance, and clearance between the stylus and the workpiece surface.

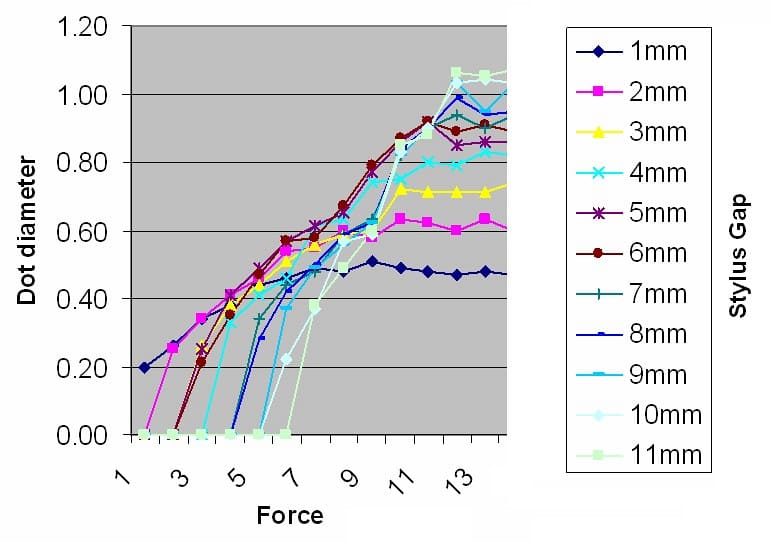

The dot peen marking machine can mark characters with a depth of 0.15 to 49.95 mm. The depth of the dot peen marking depends on the following factors:

- Marking power

- Marking gap (distance between the tip of the stylus and the workpiece)

- Workpiece hardness level

- The angle of the stylus tip

The effect of marking strength on the marking gap is shown in the following graph.

Use of Dot Peen Marking in Various Industries

Dot peen marking machines are used in a variety of industries, including the aerospace, automotive, manufacturing, transportation, and medical industries. In the aerospace and automotive industries, these machines are used for casting and metal tagging. In the manufacturing industry, these machines are often integrated into automatic and semi-automatic assembly lines and are sometimes installed as part of a test station. In the medical industry, dot peen marking is used to add identification to plastic molds and surgical instruments.

Dot Peen Marking Products for sale in Singapore

1. SIC Marking E-Mark Cordless Portable Marking Machine

E-Mark has no awkward cables that can risk shock or trip hazards. Lightweight and versatile, this completely autonomous marking gun is perfect for the identification of heavy, large, or difficult to access parts. Robust and ruggedly reliable, E-Mark's advanced mechanical precision allows for superior quality marking that is perfect for, among other things, data matrix marking.

2. SIC Marking e10 p123 Portable Marking Gun

The p123 portable dot peen marking machine is ideal for marking large and difficult-to-access parts. The specially designed front plate arches along the width to optimize marking on both flat and cylindrical surfaces. Thanks to the solenoid actuated marking pin, the p123 requires minimal maintenance and no pneumatic system. Capable of marking any material (including plastics and metals up to 62HRC), this portable engraving machine maintains a consistent quality and precise accuracy.

3. Vector VM2020 Air Pen Marking Machine

The Vector Air Pen Marking VM2020 has been devised as a versatile machine for precision dot peen marking for mass production. Powered by pneumatic air supply, the VM2020 can mark 2D codes containing huge data on the small space of workpiece permanently.

Vector's VM2020 mark characters and 2D-codes consists of dimples on workpieces by pressing the vibrating stylus tip directly. Air pen marking machine vibrates the stylus tip by pneumatic pressure.

4. Vector VM2030 Ultrasonic Pen Marking Machine

Vector Ultrasonic Pen Marking VM2030 is a precision dot peen marking machine for use in mass production. VM2030 is driven by electricity. It uses ultrasonic power to vibrate the stylus to produce markings. No air devices are required. You can use the machine simply by connecting to the power source. The use of the ultrasonic pen comes with many advantages. Firstly, this machine will produce less noise when compared to other dot peen marking machines using electromagnetic stylus. This is also remarkably effective for marking thin workpieces.

5. Vector VM1250 Multi-stylus Pen Marking Machine

Vector Ultrasonic Pen Marking VM1250 is a highly efficient precision dot peen marking machine for mass production. VM1250 is equipped with multi-stylus pen (having 4 styli) and can mark dots twice or faster than single pen models. VM1250 gives vibration priority to unworn and undamaged styli. The pneumatic system provides deep marking on your workpiece. It increases the efficiency of your work and thus lowers production costs.

Dot Peen Marking Distributor in Singapore

LFC PTE LTD is the official distributor of Sisma, SIC Marking, Pryor, and Vector marking machines in Singapore.

If you want to discuss marking machines to support your business, please contact us via the contact page.

Also visit our facebook, instagram, youtube and linkedin pages to get the latest updates about industrial equipment.