- Home

- Products

- Non-destructive Tester

- Coating Thickness Gauge

- DeFelsko Certified Coated Metal Plates

If you want to find out more about

DeFelsko Certified Coated Metal Plates

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

Ensuring Accuracy in Coating Thickness Gauges with DeFelsko Certified Coated Metal Plates Certified coated metal plates are an essential tool for ensuring the accuracy and proper functioning of coating thickness gauges, making them a crucial component of ISO and in-house quality control requirements. To maintain accuracy, many organizations require the verification of gauge accuracy on-site every time a coating thickness gauge is put into service and at regular intervals during use. Thankfully, DeFelsko-certified coating thickness standards are perfectly suited for this purpose, as they provide measured values that are traceable to a National Metrology Institution. Here are some features of DeFelsko Certified Coated Metal Plates: Used to verify the accuracy and operation of any Type 1 (mechanical) and Type 2 (electronic) magnetic, eddy-current or ultrasonic coating thickness gage Ideal for use in the calibration lab, in the field, or on the factory floor Standards with steel or aluminum substrates consist of 4 plates mounted in a protective binder Polystyrene thickness standards consist of 4 blocks supplied in a rugged acrylic storage box Individually serialized for traceability to NIST or PTB - includes a Certificate of Calibration Certified and labeled in both Metric and Imperial units Zero Plates are available for Certified Coated Metal Plates.

Ensuring Accuracy in Coating Thickness Gauges with DeFelsko Certified Coated Metal Plates

Certified coated metal plates are an essential tool for ensuring the accuracy and proper functioning of coating thickness gauges, making them a crucial component of ISO and in-house quality control requirements.

To maintain accuracy, many organizations require the verification of gauge accuracy on-site every time a coating thickness gauge is put into service and at regular intervals during use. Thankfully, DeFelsko-certified coating thickness standards are perfectly suited for this purpose, as they provide measured values that are traceable to a National Metrology Institution.

Here are some features of DeFelsko Certified Coated Metal Plates:

- Used to verify the accuracy and operation of any Type 1 (mechanical) and Type 2 (electronic) magnetic, eddy-current or ultrasonic coating thickness gage

- Ideal for use in the calibration lab, in the field, or on the factory floor

- Standards with steel or aluminum substrates consist of 4 plates mounted in a protective binder

- Polystyrene thickness standards consist of 4 blocks supplied in a rugged acrylic storage box

- Individually serialized for traceability to NIST or PTB - includes a Certificate of Calibration

- Certified and labeled in both Metric and Imperial units

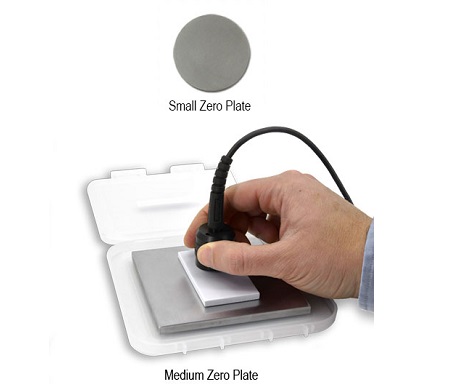

Zero Plates are available for Certified Coated Metal Plates.

Overview

TECHNICAL SPECIFICATION

DeFelsko Certified Coated Metal Plates

|

|

Order Code |

Ideal for | Approximate Thickness |

Coating/ |

Accuracy |

|||||

|

Plate 1

|

Plate 2 |

Plate 3 |

Plate 4 |

||||||

|

S1 |

PosiTector 6000 F, FS, FRS, FN, FNS, FNRS |

0 |

75 um |

250 um |

1500 um |

Epoxy |

± 0.43 um |

||

|

S2 |

PosiTector 6000 F0S, F45S, F90S

PosiTest DFT Ferrous & Combo |

0 |

75 um |

250 um |

1000 um |

||||

|

S3 |

PosiTest G & GM

PosiPen A, B & C |

0 |

15 um |

40 um |

100 um |

||||

|

A1 |

PosiTector 6000

N ,NS, NRS, FN, FNS, FNRS |

0 |

75 um |

250 um |

1500 um |

Epoxy |

± 0.43 um |

||

|

A2 |

PosiTector 6000 NAS , N0S, N45S, N90S |

0 |

75 um |

250 um |

500 um |

||||

|

A3 |

PosiTector 100B, 200, 200B

|

75 um |

125 um |

250 um |

500 um |

||||

|

All certified standards are supplied with a Certificate of Calibration traceable to NIST or PTB. |

Request a Quote

Request A Quote

Please complete the below form to receive further information.