- Home

- Products

- Non-destructive Tester

- Coating Thickness Gauge

- DeFelsko Zero Plates For Coating Thickness Gauge

If you want to find out more about

DeFelsko Zero Plates For Coating Thickness Gauge

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

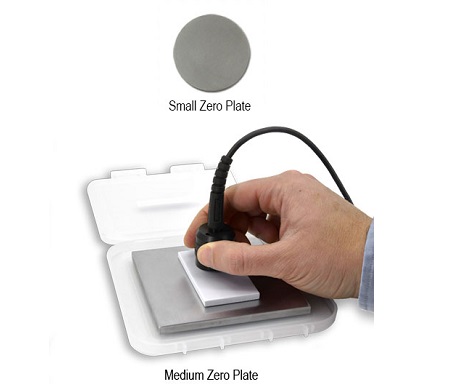

Zero Plates are available as uncoated precision machined steel or aluminum (6061-T6) in a variety of plate sizes. What are zero plates used for? Use with Certified Coated Metal StandardsCoated Metal Standards for magnetic and eddy current gages usually include an uncoated zero plate. The first gage measurement is taken on the zero plates to verify that the gage measures zero correctly. If not, electronic gages can usually be adjusted to "0" on the zero plates. After this adjustment is performed, the gauge should measure within tolerance on the coated standards. Use with certified and non-certified plastic shims and polystyrene blocksA zero plate provides a convenient base onto which plastic shims and polystyrene blocks can be placed for verification purposes. Check zero, adjust to "0" if necessary, then place the shim/block on the zero plates and measure. Substitute as a base for materials without a substrateZero plates can be used to provide a substrate where none exists. Large sheets of material such as paper, plastic, fabric, and rubber can be measured with a coating thickness gauge by placing the material over zero plates. This is useful when the measured item is too large to access with a micrometer or other device. For example, the screen printing industry uses zero plates to measure the thickness of the "substrate" that is printed.

Zero Plates are available as uncoated precision machined steel or aluminum (6061-T6) in a variety of plate sizes.

What are zero plates used for?

Use with Certified Coated Metal Standards

Coated Metal Standards for magnetic and eddy current gages usually include an uncoated zero plate. The first gage measurement is taken on the zero plates to verify that the gage measures zero correctly. If not, electronic gages can usually be adjusted to "0" on the zero plates. After this adjustment is performed, the gauge should measure within tolerance on the coated standards.

Use with certified and non-certified plastic shims and polystyrene blocks

A zero plate provides a convenient base onto which plastic shims and polystyrene blocks can be placed for verification purposes. Check zero, adjust to "0" if necessary, then place the shim/block on the zero plates and measure.

Substitute as a base for materials without a substrate

Zero plates can be used to provide a substrate where none exists. Large sheets of material such as paper, plastic, fabric, and rubber can be measured with a coating thickness gauge by placing the material over zero plates. This is useful when the measured item is too large to access with a micrometer or other device. For example, the screen printing industry uses zero plates to measure the thickness of the "substrate" that is printed.

Overview

TECHNICAL SPECIFICATION

| Order Code | Ideal For | Type | Plate Size |

| STDZSTL |

PosiTector 6000 F, FS, FRS, FN, FNS, FNRS, FXS, FNDS, F microprobes PosiTest DFT Ferrous Combo |

Steel | Small Disk Diameter: 38 mm (1.5") |

| STDZALM |

PosiTector 6000 N, NS, NAS, NRS, FN, FNS, FNRS, FNDS, N microprobes PosiTest DFT Combo |

Aluminum | Small Disk Diameter: 38 mm (1.5") |

| STDZSTLM | PosiTector 6000 FT, FTS, FTRS, FNTS, FKS, FHXS probes | Steel | Medium Square 100 mm x 100 mm x 6 mm (4" x 4" x 0.25") |

|

STDZALMM

|

PosiTector 6000 FNTS, NKS probes | Aluminum | Medium Square 100 mm x 100 mm x 6 mm (4" x 4" x 0.25") |

| STDZSTLL | PosiTector 6000 FLS, FJS, FNGS probes | Steel | Large Square 180 mm x 180 mm x 6 mm (7" x 7" x 0.25") |

Request a Quote

Request A Quote

Please complete the below form to receive further information.