If you want to find out more about

DOALL Tungsten Carbide Bandsaw Blade Olympia

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

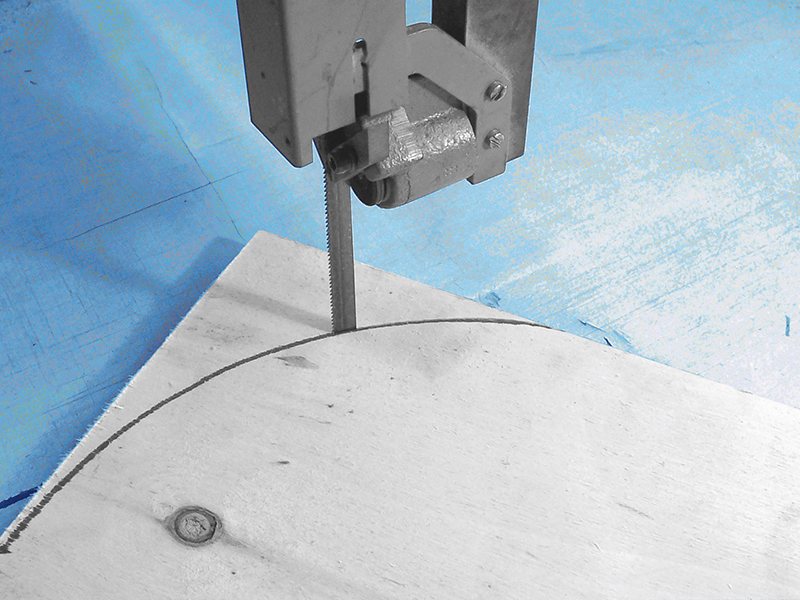

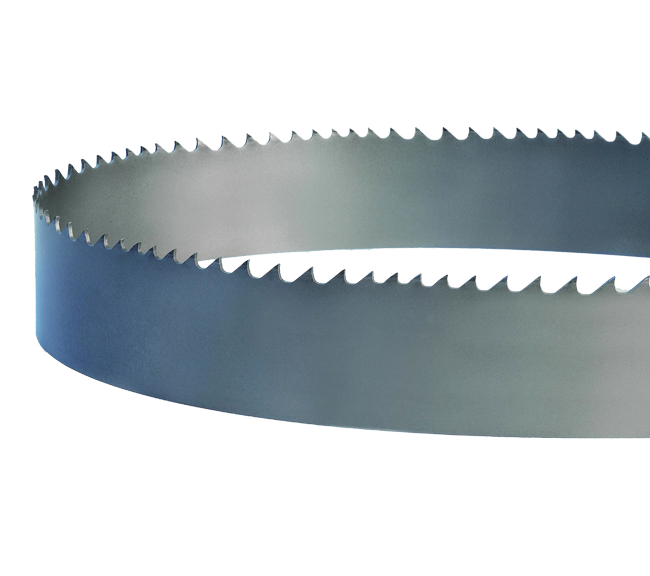

DoALL Olympia bandsaw Blade is made of carbon steel material for various bandsaws application. The sawing teeth are heat treated to provide high-strength steel base which precisely cut against fibrous matter and structure of wood as well as plastic material. The sawing teeth are harder (suitable for many alloy and ferrous material), meanwhile, the backing area itself is flexible for more resistant to cracking and breaking (which is desirable when you are working with the busy queue). Depends on your machinery set up, DoALL Olympia bandsaw Blade performs consistently balanced between the power to cut ratio for a cost-effective job on various woodworking job, general engineering and art-crafts workshops. You can work on logs, veneers such as plywood, MDF or particle board, some engineered wood products like oriented strand board (OSB), engineered cellulosic products from other lignin-containing materials such as rye straw, wheat, and hemp stalks, Acrylic, Plastic, Pelts, Hard Rubber and many more. Features : Precision milled teeth Flame hardened tooth tips Spring hardened back Benefits : Long blade life Strong blade for accurate contour sawing Applications : Typical woodworking and plastic operations

DoALL Olympia bandsaw Blade is made of carbon steel material for various bandsaws application. The sawing teeth are heat treated to provide high-strength steel base which precisely cut against fibrous matter and structure of wood as well as plastic material. The sawing teeth are harder (suitable for many alloy and ferrous material), meanwhile, the backing area itself is flexible for more resistant to cracking and breaking (which is desirable when you are working with the busy queue).

Depends on your machinery set up, DoALL Olympia bandsaw Blade performs consistently balanced between the power to cut ratio for a cost-effective job on various woodworking job, general engineering and art-crafts workshops. You can work on logs, veneers such as plywood, MDF or particle board, some engineered wood products like oriented strand board (OSB), engineered cellulosic products from other lignin-containing materials such as rye straw, wheat, and hemp stalks, Acrylic, Plastic, Pelts, Hard Rubber and many more.

Features :

- Precision milled teeth

- Flame hardened tooth tips

- Spring hardened back

Benefits :

- Long blade life

- Strong blade for accurate contour sawing

Applications :

- Typical woodworking and plastic operations

Overview

Customer value

Built to perfoms

TECHNICAL SPECIFICATION

DOALL Tungsten Carbide Bandsaw Blade Olympia Ordering Guide:

| Metric | Olympia | ||||

| Width | Gauge | 1,3 | 2 | 3 | 4 |

| 6 | 0,6 | 358-054 | |||

| 10 | 0,6 | 358-108 | 358-118 | ||

| 0,8 | 358-104 | 358-114 | |||

| 13 | 0,6 | 358-152 | |||

| 0,8 | 358-156 | ||||

| 16 | 0,8 | 358-211S | 358-215 | ||

| 20 | 0,8 | 358-252 | 358-256 | ||

| 358-254W | |||||

| 25 | 0,9 | 358-304 | 358-328 | ||

| 32 | 0,9 | 358-356 | 358-362 | ||

| 38 | 0,9 | 358-423 | |||

| 50 | 0,9 | 358-513 | |||

| Claw tooth | |||||

| S | Straight set | ||||

| W | Wide-set | ||||

| Coil lengths up to 20 mm 152,4 mm and over 20 mm 91,4 mm | |||||

Request a Quote

Request A Quote

Please complete the below form to receive further information.