If you want to find out more about

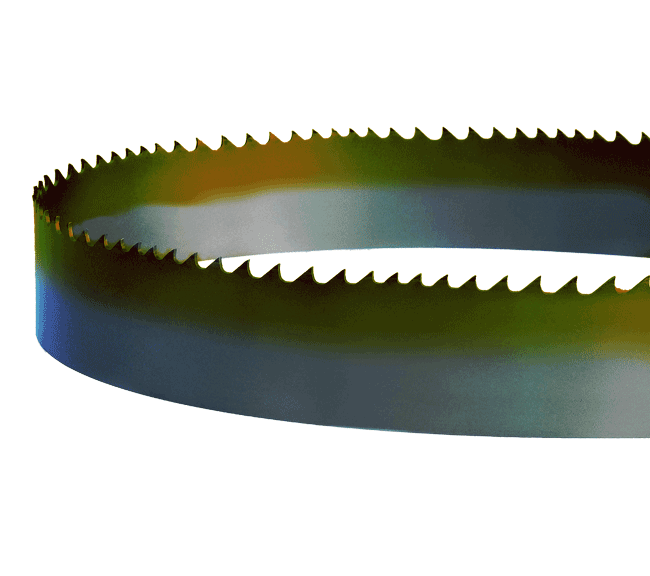

DoALL Penetrator Saw Blade TiN Coated Series

Talk to us at :

(65) 6749 9697

sales@lfc.com.sg

DoALL Penetrator Saw Blade TiN Coated Series is designed with a high speed steel tooth tips which curved and coated with “TiN” which is an extremely hard ceramic to improve the blade's surface properties when working with high tensile material with thinner or aerosol lubrication (solid iron etc.). The sawing teeth are harder compared to regular HSS model, meanwhile, the backing area of the DoALL Penetrator Saw is softer and also flexible for more resistant to cracking and breaking (which is desirable when you are working with busy queue). Depends on your machinery set up, DoALL TiN Coated Saw Blade performs consistently balanced between power delivery to cut ratio for a cost effective job on cutting solids, corrugated and heavy wall tubing. DoALL Penetrator Saw Blade TiN Coated Series fare better in cutting speed and durability demanded when you are having an autonomous cutting system with minimal operator supervision. DoALL Penetrator TiN Coated Saw Blade is particularly suitable when you need the reliability and versatility in working with oil and gas tube, high compression chemical tube and blanks for CNC fabrication which may varies from each customer. High Line Bi-Metal Blade For Solids & Heavy Wall Tubing Coating provides longer blade life Available in Penetrator en Supreme Features Available in TiN Penetrator (M42) and TiN Supreme (Powder metal) Low surface friction Benefits Improved wear resistant Extended blade life Applications Use these blades to saw any material recommended for Penetrator or Supreme blades For large volume cutting jobs

DoALL Penetrator Saw Blade TiN Coated Series is designed with a high speed steel tooth tips which curved and coated with “TiN” which is an extremely hard ceramic to improve the blade's surface properties when working with high tensile material with thinner or aerosol lubrication (solid iron etc.). The sawing teeth are harder compared to regular HSS model, meanwhile, the backing area of the DoALL Penetrator Saw is softer and also flexible for more resistant to cracking and breaking (which is desirable when you are working with busy queue).

Depends on your machinery set up, DoALL TiN Coated Saw Blade performs consistently balanced between power delivery to cut ratio for a cost effective job on cutting solids, corrugated and heavy wall tubing. DoALL Penetrator Saw Blade TiN Coated Series fare better in cutting speed and durability demanded when you are having an autonomous cutting system with minimal operator supervision. DoALL Penetrator TiN Coated Saw Blade is particularly suitable when you need the reliability and versatility in working with oil and gas tube, high compression chemical tube and blanks for CNC fabrication which may varies from each customer.

High Line Bi-Metal Blade For Solids & Heavy Wall Tubing

- Coating provides longer blade life

- Available in Penetrator en Supreme

Features

- Available in TiN Penetrator (M42) and TiN Supreme (Powder metal)

- Low surface friction

Benefits

- Improved wear resistant

- Extended blade life

Applications

- Use these blades to saw any material recommended for Penetrator or Supreme blades

- For large volume cutting jobs

Overview

Built to perfoms

Customer values

TECHNICAL SPECIFICATION

DoALL Penetrator Saw Blade With TiN Coated Model Ordering Guide:

| Metric | TiN Coated Penetrator | ||||||

| Width | Gauge | 1-1,5 | 1,5-2 | 2-3 | 3-4 | 4-6 | 5-8 |

| 27 | 0,9 | 319-423 | 319-598 | 319-615 | 319-645 | ||

| 34 | 1,1 | 319-558 | 319-533 | 319-567 | 319-789 | ||

| 41 | 1,3 | 319-880 | 319-640 | 319-319 | 319-375 | ||

| 54 | 1,6 | 319-071 | 319-070 | 319-327 | 319-085 | ||

| 67 | 1,6 | 319-185 | 319-184 | ||||

| 80 | 1,6 | 319-433 | |||||

DoALL Supreme Saw Blade With TiN Coated Model Ordering Guide:

| Metric | TiN Coated Supreme | |||

| Width | Gauge | 2-3 | 3-4 | 4-6 |

| 27 | 0,9 | 319-634 | 319-635 | |

| 34 | 1,1 | 319-656 | 319-658 | 319-346 |

| 41 | 1,3 | 319-809 | 319-814 | |

|

NOTES: Be advised that with suitable machining speed, types and flow rate of coolant will prevent the DoALL saw blade from overheating, improve precision, remove the slurry from the cut, and extend the life of the blade at the same time. |

You can also download DoALL Saw Blade catalogs here

Request a Quote

Request A Quote

Please complete the below form to receive further information.